|

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

Villain of global warming and ocean acidification, the excess of carbon dioxide generated by human activities can be used to produce very useful compounds.

One example is the production of fuels from carbon dioxide, water and sunlight through photosynthesis-like processes, in which catalytic materials can play a key role in significantly increasing the efficiency of reactions.

Scientists from several countries are currently addressing a number of scientific and technological challenges related to the “recycling” of carbon dioxide. Their ultimate objective is to enable the so-called circular carbon economy, a system based on the use of carbon dioxide, renewable energy and environmentally friendly materials, and on the principle of minimizing waste and maximizing reuse.

One of these scientists is Joan Ramón Morante Lleonart, director of the Institute of Energy Research of Catalonia (IREC) and Professor of the Faculty of Physics of the University of Barcelona. Morante, who holds a PhD in Physics from the University of Barcelona, is also the editor-in-chief of the Journal of Physics D: Applied Physics (IOP Publishing). According to Google Scholar, his scientific production has more than 24,000 citations and his h-index is 82.

This Spanish scientist will be in September at the XVII B-MRS Meeting, where he will offer a plenary lecture entitled “Catalyst materials for solar refineries, synthetic fuels and procedures for a circular economy of the CO2”.

See our brief interview with Professor Morante.

B-MRS Newsletter: – Which materials can play an important role in circular economy of the CO2?

The circular CO2 economy implies different materials. First, the CO2 itself that must be captured and purified. These processes are not direct and even require the improvement of these steps, especially the development of materials for membranes that help to properly separate the CO2 from other components that, although smaller, such as sulfur can degrade the catalytic materials.

This is necessary both for the capture of CO2 from the carbon consumption of fossil origin and for the CO2 contained in the processes of fermentation and putrefaction that produce biogas.

However, apart from the caking process, the most critical point that requires the contribution of a deep knowledge of the materials is the step of the catalytic transformation of CO2 to achieve its direct reduction to products such as CO, methanol, formic acid, etc. . or its transformation, using other feed-stock, to methane (synthetic methane) or other products for example by hydrogenation of CO2 (methanation according to the reaction named reaction of Paul Sabatier).

These processes require not only the development of efficient catalysts but also materials for new reactors that combine their resistance to use, being able to resist corrosive conditions together with their thermal dissipation capacity in some cases, or electrical conductivity in other cases, or the lighting conditions for those cases in which the solution passes through the direct transformation of CO2 using the photons of the sun.

The development of these materials offers a magnificent opportunity to apply nanomaterials, being necessary to have large active surfaces per gram of material and controlled characteristics at the nanometer level avoiding degradation phenomena.

All these features constitute a great opportunity for developing science and technology promoting, at the same time, the transfer of science toward larger knowledge as well as new business opportunities giving answers to a truly problem of our society as it is the consumption of fossil energy sources that generate climatic change.

B-MRS Newsletter: – We want to know your work a little more. Choose your favorite scientific contribution and describe it briefly, in addition to sharing the reference.

Some years ago I was working on the compatibility of different materials with the microelectronics processes just looking for the integration of different functionalities (sensors and actuators) together with the processing units. In a way, it is a biomimetic activity because the scientific community tries to do something similar to living beings, that is, put the senses (sensors) to have a signal as information and connect it to a brain (processors) to process it.

In these activities it was necessary to generate electrical signals and control them. From this, I moved to generate electrical signals in different environments but now considered not as a signal of information but as a source of energy.

Again, the best features are achieved by controlling these phenomena on a nanometric scale and that is why now my activities are focused on “nano energy” in order to produce GWh.

Currently, I am focused in the mechanisms of energy transfer in solid interfaces involving electrons, photons and phonons as well as chemicals.

Likewise, I am specialized in the development of renewable energy devices and systems for applications in the field of energy and environment based on nano structures and their functionalization. So I have paid my attention on advanced materials and structures for artificial photosynthesis including the production of hydrogen and fuels at solar refineries. One of my main objectives is how to storage the electrical energy beyond the hydraulic pumping or the limited capacity by using batteries. Chemical storage using hydrogen or synthetic methane or biomethane constitute my main goal although I am also working on electrochemical batteries.

So if I check my last published papers, from one hand, I could highlight “Recent developments in organic redox flow batteries: A critical review” published in J. of Power Sources which is going beyond the lithium ion approaches for batteries , but from the other hand, I would like to underline “Enhanced photoelectrochemical water splitting of hematite multilayer nanowire photoanodes by tuning the surface state via bottom-up interfacial engineering” or “A prototype reactor for highly selective solar-driven CO2 reduction to synthesis gas using nanosized earth-abundant catalysts and silicon photovoltaics” both published in Energy and Environmental Science. Especially the last one is very representative of the above discussed issues.

B-MRS Newsletter: – Choose also a technological contribution that you have participated in: a case of transfer to the industry or a patent, for example, and make a brief description.

Our institute promotes and encourages the transfer of technology and the generation of patents only linked to its industrial exploitation.

During these last years we have patented some aspects of the technology to produce industrial solar or synthetic fuels. So with one of our industrial collaborators some patents have been carried out as “filter-press photoelectrochemical water oxidation and CO2 reduction cell” or “substrate-electrode interface illuminated photoelectrodes and their photoelectrolechemical cells”.

However I would like to indicate another of the patents made in collaboration with other groups that open a new perspective to the catalytic materials for the catalytic conversion of CO2. Its title is “procedure for the reduction of carbon dioxide to methane by catalytic activated by DBD plasma” and deals with the development of new concepts of catalytic materials that are subjected to the action of a plasma which changes all the conditions of the chemical reactions that take place on the surface of the catalyst at the same time that the own plasma contributes a complementary energy to have a different catalytic behavior. This allows to develop other behaviors and concepts. Thus, it has been achieved under adiabatic conditions to have a conversion rate of CO2 at room temperature comparable to that of a standard isothermal thermochemical conversion process at 300-400 °C. This opens new routes to implement more economical and high performance reactors.

—————————–

For more information on this speaker and the plenary talk he will deliver at the XVII B-MRS Meeting, click on the speaker’s photo and the title of the speech here https://www.sbpmat.org.br/17encontro/home/

The “old-fashioned” sewing thread universally used, for example, to sew buttons, has recently been transformed by a Brazilian scientific team into an electrically conductive and multifunctional material. In fact, the various uses of this new sewing thread go far beyond sewing. It works very well as a mini electric heater, as a component of supercapacitors (devices that store and release energy, similar to batteries) and as a bactericidal agent. In addition, the thread is flexible and comfortable to the touch, and retains its electronic properties even after being washed, twisted, curled or folded repeatedly.

With these characteristics, this fiber can play an important role in wearable electronics – the set of electronic devices designed to be worn on the human body, incorporated into clothing or accessories.

“As the thread is a basic element for the design of textiles, we imagine that any wearable product can make use of this technology”, says Helinando Pequeno de Oliveira, a professor at the Brazilian Federal University of the Vale de São Francisco (Univasf) and leader of the scientific team that developed the conductive and bactericidal thread. Together with three other authors, all linked to Univasf, Oliveira authors an article reporting this work, which was recently published in the journal ACS Applied Materials and Interfaces.

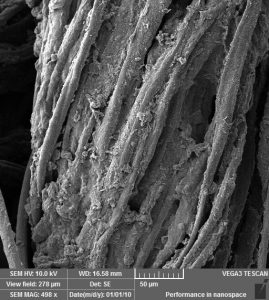

The conductive and bactericidal fiber of Oliveira and his collaborators is made of a composite material: cotton thread of 0.5 mm diameter, coated with carbon nanotubes and polypyrrole. The resulting material presents, in addition to high electrical conductivity, good electrochemical activity – necessary characteristic for it to be used in supercapacitors.

To make the conductive fiber, the Univasf team developed a very simple process, formed by two main stages. In the first step, pieces of cotton thread are submerged in a paint of carbon nanotubes, previously modified in order to increase their interaction with the cotton. As a result, the thread is coated by a continuous network of interconnected nanotubes.

The second step is intended to coat the fibers with a second material: polypyrrole. To do this, a solution is initially formed by pyrrole and the solvent hexane, in which the fibers coated with nanotubes are submerged. Thereafter, another solution is poured over this preparation. The second solution consists of water and some compounds, which will be incorporated in very small amounts into the chemical composition of the polypyrrole in a process called “doping” of the material. At the interface between both solutions, which do not mix, the small pyrrole molecules are bound together, resulting in the formation of polypyrrole macromolecules that are deposited on the surface of the fibers. This process, in which a polymer forms at the interface between two solutions, is called “interfacial polymerization”. “Given the good polypyrrole doping level (optimized for this synthesis) and its strong interaction with the functionalized nanotubes, the resulting fibers display excellent electrical properties,” says Professor Oliveira.

The scientific team also produced some variants of this sewing conductive thread. For example, a fiber without carbon nanotubes and another fiber whose polypyrrole coating was produced by means of non-interfacial polymerization. However, the lines with carbon nanotubes and interfacial polymerization showed the best electrical and electrochemical performance.

Heaters and supercapacitors made of cotton fibers

“The high electrical conductivity (together with the good porosity of the material) made of the material a great prototype for application in electrodes of supercapacitors”, says Oliveira. “These properties also made it possible to use it as an electric heater with very low operating voltages (of the order of a few volts). In addition to these applications, the antibacterial potential of the matrix”, he adds.

In addition to testing the performance of the conductive and bactericidal fiber in isolation in the laboratory, Oliveira and his collaborators developed a proof of concept. “We used a needle to sew the thread in a glove”, says the professor. With this we could monitor the temperature that the hand, wearing this glove, would reach when we connected the device to a power supply,” he explains.

The heating system tested on the glove can be adapted to a variety of contexts, such as an ambulatory version of thermotherapy (therapeutic heating of body regions, which is often used in physiotherapy sessions)with the added advantage of antibacterial action. This property is particularly interesting in materials that are used in contact with the skin, since, in this way, they avoid diseases and odors. In the case of polypyrrole, the action occurs when the material electrostatically attracts the bacteria and promotes the breakdown of its cell wall, inhibiting its proliferation.

A possible wearable product based on the conductive sewing thread is a thermal jacket.It could be powered by a solar cell incorporated into the jacket, or by means of triboelectric devices, which would reap the energy generated by the user’s movement of the jacket.The resulting energy would be stored in a supercapacitor made with the conductive fiber. Tailored to the jacket, the supercapacitor would provide electricity to the heater when needed.

Another example is the energy storage t-shirt, in which Professor Oliveira’s group is currently working to generate a marketable product. We are currently optimizing the production of supercapacitors in pieces of cotton and lycra fabrics as a way to connect them directly to portable power generators, thus enabling the development of energy storage t-shirts,” says Oliveira.

Science and technology developed in the backlands

The work reported in the ACS Appl. Mater. Interfaces and their developments were fully carried out at the Materials Science Research Institute of Univasf, on the campus of the municipality of Juazeiro, located in the north of the state of Bahia. Univasf, which has six campuses located in the interior of the states of Bahia, Pernambuco and Piauí, was created in 2002 and inaugurated in 2004. In the same year, Oliveira became a professor at the institution.

The development of the conductive cotton lines was born from a thread of research on electronics and flexible devices, created in 2016. In 2017, the idea became the theme of the master’s work of Ravi Moreno Araujo Pinheiro Lima, guided by Professor Helinando Oliveira, within the Postgraduate Program in Materials Science at Univasf – Juazeiro, created in 2007. Post-doc José Jarib Alcaraz Espinoza, who was optimizing syntheses of conductive polymers for supercapacitors, adapted a methodology to interfacial polymerization in cotton. With this, the researchers realized that the conductor lines worked as good supercapacitor electrodes, and fabricated these devices. At the same time, with the collaboration of Fernando da Silva Junior, a doctoral student of the institutional postgraduate program Northeast Network of Biotechnology, the team tested the action of the material against the bacterium Staphylococcus aureus, responsible for a series of infections of varying degrees of severity not human.

“These results reflect Brazil’s investment in the internalization of its network of federal teaching and research institutions. With this, the migration of the sertanejo towards the great capitals in the search for knowledge has been reduced. Now there is also more science being produced in the northeastern backlands”, says Professor Oliveira. “However, recent cuts in S & T have launched a huge cloud of uncertainty about the future of science in the country (and in particular about these young institutions). The Brazilian government does not have the right to throw so many dreams in the trash. Science needs to overcome this crisis,” completes the researcher.

[Paper: Multifunctional Wearable Electronic Textiles Using Cotton Fibers with Polypyrrole and Carbon Nanotubes. Ravi M. A. P. Lima, Jose Jarib Alcaraz-Espinoza , Fernando A. G. da Silva, Jr., and Helinando P. de Oliveira. ACS Appl. Mater. Interfaces, 2018, 10 (16), pp 13783–13795. DOI: 10.1021/acsami.8b04695]

About 1700 abstracts were submitted to the XVII B-MRS Meeting, with oral or poster presentations at one of the 21 symposia that comprise this edition of the event.

The works submitted are signed by authors from 42 countries worldwide and, within Brazil, from 25 states of the federation, representing all regions of the country.

Some of the symposia had more than 100 papers submitted. This was the case for the symposia on (nano) materials for biomedical applications (224 submissions), surface engineering (120), metal oxide nanostructures (118), and organic electronics and bioelectronics (117).

B-MRS member Victor Carlos Pandolfelli, professor in the Department of Materials Engineering at the Federal University of São Carlos (DEMa-UFSCar), was reelected as a member of the advisory board of the World Academy of Ceramics (WAC) to fulfill his second 4-year term (2018 to 2022). The board will include the Brazilian researcher, along with Professor Gary Messing (Penn State) and Dr. M. Singh (NASA), as representatives of the Americas.

In order to be part of the WAC advisory board, it is necessary to be a member of the Academy and be elected by vote of the members of the same region of the planet (in this case, the American continent). The names of the most voted must be endorsed by the presidency of the Academy. To be a member of the WAC, one must undergo a selection process that includes nomination by two effective members, evaluation of the application by a peer committee selected by the Academy, and final approval by at least ten of the twelve members of the advisory board.

According to Professor Pandolfelli, some of the activities he will hold in the council over the next four years are: reviewing the WAC admission rules, defining the members who will participate in the new candidate selection processes, defining the topic and speakers for technical presentations and awards in the scientific forum for members of the Academy.

The inauguration and first meeting of the new council will be held next June in Perugia (Italy).

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

Yesterday, April 30th, was the deadline for abstract submission to the 17th Brazil-MRS meeting, Natal, 2018. However, the organization received a number of messages from last minute authors experiencing system difficulty to send their contributions. Therefore, the system will remain open until May 4th to receive your abstract.

For details, visit https://www.sbpmat.org.br/17encontro/home/

Brazil-MRS 2018 Organizing Committee

Guess what it is.

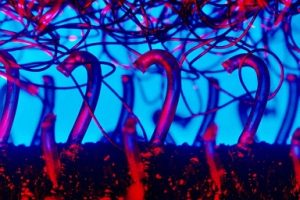

It is perhaps the best known among biomimetic products (products developed by humans to imitate living beings that have been “developed” by nature over many millions of years).

It is an invention that became innovation (entered the market) and after some time it was widely accepted by consumers. Its use spread on planet Earth (on land, water and air) and reached the Moon

It is an invention that was the seed of a multinational company that today markets thousands of products.

Have you guess it? Here’s another clue.

The word popularly used to designate this product actually corresponds to a trademark, not to the object itself. It is a case of metonymy.

Do you know what invention we’re talking about? Not yet? Then, carefully read the history of this invention.

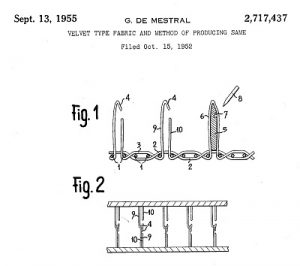

It all began in 1941 in the Swiss Alps. George de Mestral, a thirty-something Swiss electronics engineer, was back from a walk in the mountain with his dog, removing the burrs that had stuck to the dog’s hair and his clothing during the walk. These small spiked balls are the fruits of some plant families, and their ability to attach to animal hair is an advantage of these species as it helps to disperse the seeds that are inside the fruit.

The story goes that at that moment Mestral wondered why the burrs stuck and decided to look at them with a microscope in his house. The engineer then noticed that the fixation occurred between two elements. On the one hand, tiny loops formed on the matted coat of the dog or on the surface of the tissues. On the other hand, the tips of the little thorns, which were shaped as a hook. These flexible little “hooks” were tangled in the loops and only loosened by pulling them out with some force. With a biomimetic look and inventive spirit (Mestral presented his first patent at age 12), he saw in this natural system of reversible fixation, a model to artificially develop a very useful product.

Have you guessed what the invention is? Whether yes or no, see how the rest of the story.

For some years, George de Mestral faced the challenge of creating a prototype of this system of tiny hooks and loops. The main problem was to develop a method which would allow manufacturing a strip of fabric that could push upward, perpendicularly, a considerable amount of flexible hooks.

It seems the process was not easy, and that Mestral had a hard time finding people to help him produce this fabric. However, in 1952, he filed a patent application with the United States patent office about such a fabric and how to fabricate it. In the document, Mestral presented a “velvet-like fabric,” as it was covered, like velvet, with a dense “forest” of upright wires. However, unlike velvet, in the new fabric the threads were made of nylon (a newly created material), and a good part of the threads had hook-like tips. The manufacturing process proposed in the patent was similar to traditional velvet, using a loom, but with a few additional tricks to shape the hooks at the ends of the nylon strands.

Granted in 1955, this seems to be the first in a series of patents by the Swiss engineer around the invention that is the answer of our guessing game.

Mestral then founded a company to manufacture and market the product. However, the manufacturing system he had proposed in the patent was not fully mechanized and did not allow it to be produced at an industrial scale. The finishing process to produce the hooks was manual… and quite time consuming. The engineer had to wait about 20 years from his “eureka!” for a loom capable of mass producing the fabric with the tiny hooks.

When coupling the fabric with the hooks with another fabric covered by a tangle of loops, Mestral obtained a reversible fixation product with a thousand and one utilities, and with potential to revolutionize the market of zippers and buttons.

At first, the system invented by Mestral did not look very attractive. But little by little he gained visibility (from newspaper columns to futuristic films) and was adopted by various segments. In the late 1960s, for example, the invention began to be used by sports shoes manufacturers, replacing shoelaces and stood out in the NASA space program “Apollo” as a system to attach small objects to the walls of the spacecraft, preventing them from floating.

Currently the product is incredibly widespread. It helps solve small day-to-day problems in offices, shops, residences, hospitals, laboratories, walkways, schools…

Need another clue to guess what the invention is? Here goes the last one:

In 1956, George de Mestral obtained the trademark registration for his company. The name invented by the Swiss is the combination of two words in French (predominant language in the region of Switzerland where he was born and died): “velours” (velvet) and “crochet” (hook).

We do not need to pronounce the name of this invention, do we? Mainly because it’s forbidden to use the term “Velcro ®,” as it is a registered trademark of this multinational company which markets this and other similar products, and is also the trademark used for all the company products, not just for “hook and loop fastener.” Go explain this to the children, who really like V________, especially in sports footwear…

A Brazilian scientific team announced in Nature Physics (impact factor 22,806), a remarkable novelty about the atomic and subatomic dimension of nature, object of Quantum Physics, in which tiny particles that also behave like waves move around without stopping.

The team, led by Professor Sergio Machado Rezende, was able to experimentally detect, for the first time in science history, phonons with spin – something like a collective vibration of interconnected atoms (phonon) spinning around an axis (spin). “Never had anybody observed a phonon with spin before these experiments,” contextualizes Prof. Rezende (Federal University of Pernambuco, UFPE).

The research was entirely carried out in the Department of Physics of UFPE, with funding from Brazilian research support agencies (CNPq, CAPES and FINEP and FACEPE).

The spin is a property of subatomic particles, and it is the origin of magnetic properties in materials. In a first approach to the concept, it can be represented as a rotational movement of the particle.

The discovery could have an important effect on the so-called “spintronics,” both from a fundamental (understanding of phenomena) and applied point of view. Just as electronics uses the electric charge of electrons to develop technology, the still incipient spintronics takes advantage of spin to encode and store data, transport, and decode them. That is why the evidence presented in the article of Nature Physics opens possibilities of employing phonons in the development of spintronic devices.

The research was developed within the PhD thesis of José Holanda da Silva Júnior, defended on April 20 of this year at UFPE, and guided by Professor Sergio Rezende (known for having held the position of Minister of Science and Technology in Brazil from 2005 to 2010).

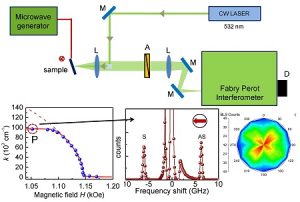

The idea of the thesis work was to generate a spin wave (a collective excitement of spins) into a ferromagnetic material and convert it into an elastic wave (a collective vibration of a network of atoms). In quantum terms, the goal was to convert “magnons” into “phonons” – a transformation that can be achieved since in ferromagnetic materials the motion of spins can cause vibrations in the network of atoms.

The idea of the magnon-phonon conversion was well studied in the 1960s and 1970s, Rezende comments. However, at that time it was not possible to obtain clear experimental evidence of the conversion, since the materials available to make the experiments limited the observation of the effect. “Cylinders of ferromagnetic materials were used,” says Rezende. “The effect occurred, but it was inside the material and there was no way to test if it was actually occurring,” he adds. To obtain definitive evidence, it was necessary to use very thin layers of ferromagnetic material.

In the last 20 years, explains Rezende, technology has been developed to make thin films of various materials. As a result, the academic interest in magnon-phonon conversion has returned, generating numerous advances in the understanding of the phenomenon in the last decade.

In this new context, José Holanda, his advisor Prof. Rezende and collaborator Prof. Antônio Azevedo da Costa were able to manufacture a thin film of the most suitable ferromagnetic material to study the magnon-phonon conversion, the yttrium and iron grenade. With this thin film, the team prepared samples in the form of tapes of 2 x 12 square millimeters of surface and 8 micrometers of thickness, and used them to perform two types of major experiments.

The first consists, in broad lines, of applying microwave radiation to one of the two ends of the film, generating spin excitations in the material. Consequently, the spin is oriented around the magnetic field that is applied (phenomenon known as “precession”). This collective precession starts at one end of the sample and propagates as a real “spin wave” until it reaches the other end.

If the magnetic field applied to the sample is uniform, the spin wave attenuates itself and does not become an elastic wave. Therefore, the Pernambuco team used rare earth magnets (one at each end of the sample) to cause variations in the magnetic field along the film, following the spin wave displacement.

The experiments with microwaves generated evidence that the magnon-phonon conversion was taking place, but the group considered it important to confirm, or not, the results through measurements of the so-called Brillouin scattering. In this experiment, laser light is applied at some point in the sample and the scattered light is analyzed. The result allows determining the nature of the excitation (in this case, magnon or phonon) that is interacting with light. “The great advantage of using a film instead of a massive material is that you can focus the laser at any position in the film and can vary the angle of incidence,” explains Rezende.

Through Brioullin scattering, the team not only could verify that the spin wave (magnon) subjected to a non-uniform magnetic field had actually converted into an elastic wave (phonons), but also they came upon a surprise: these phonons spread circularly polarized light. – evidence that they had spin. “We did not expect that the phonon produced by the conversion of the magnon also had a certain rotation motion, which is what we call spin,” says Rezende.

After making this discovery experimentally, the team made the corresponding theoretical calculations. “We confirmed that the theory actually predicted that the phonon had spin, but we did not know the theory before,” Professor Rezende reveals.

[Paper: Detecting the phonon spin in magnon–phonon conversion experiments. J. Holanda, D. S. Maior, A. Azevedo & S. M. Rezende. Nature Physics (2018) doi:10.1038/s41567-018-0079.]

Instructions for authors: https://www.sbpmat.org.br/17encontro/authors/