Bacterial biofilms are formed by communities embedded in a self-produced polymeric matrix forming a three-dimensional structure. Biofilms grow attached to the most diverse surfaces, natural or artificial, and can include a variety of bacteria and fungi. When found on our teeth, these microbial communities can cause well-known health damage, such as dental caries. Even inside the mouth, where biofilms tend to form, dental implants can also be harmed by the action of biofilms. In fact, the main cause of failure in dental implants is related to infections in the tissues surrounding the implant, due to bacterial accumulation on the titanium screws implanted by a surgeon dentist in the jaw bone or maxilla to support the dental prosthesis.

In light of this problem, a team of researchers from areas related to dentistry and materials developed a coating capable of reducing the adhesion of bacteria and fungi to the titanium surface, thus attacking the formation of biofilms in its initial stage. In the new coating, the bacterial adhesion was eight times less than in uncoated titanium. In addition, the coating changed the composition of the microbial population in the biofilms that appeared on the surface. Thus, the presence of bacteria directly responsible for generating infections around the implants was seven times less in the coating than in the uncoated titanium. “Our coating not only reduced the adhesion of microorganisms, but also modified its composition to a less aggressive host profile,” summarizes professor Valentim Adelino Ricardo Barão (UNICAMP), corresponding author of the paper related to the study, recently published in ACS Applied Materials and Interfaces. Finally, in addition to generating antibiofilm properties on titanium, the coating maintained this material’s biocompatibility, allowing the growth of human cells on its surface, and increased its resistance to corrosion.

According to the authors of the work, this new coating may be a promising strategy to control the formation of biofilms in titanium implants and thus reduce the development of microbial infections. “Countless coatings have been developed in this area,” contextualizes Professor Barão. “However, the ones available on the market aim, mainly, to improve biomechanical properties and biocompatibility, but not effective in reducing the accumulation of microorganisms.” According to the authors of the article, in order to apply coated titanium to patients and make it available on the market, it would be necessary to test its insertion as a dental implant in animal models and, finally, to conduct a controlled clinical trial that contemplates the insertion of the material in humans.

From developing the material to in vitro and in situ studies

Nociti, Magda Feres, Elidiane Cipriano Rangel, and Valentim Adelino Ricardo Barao.

The research was carried out within the doctorate of João Gabriel Silva Souza, with guidance from Professor Barão and funding from Brazilian agencies Fapesp and Capes. The thesis was defended in 2019 in the Graduate Program on Dental Clinic of the School of Dentistry at UNICAMP Piracicaba.

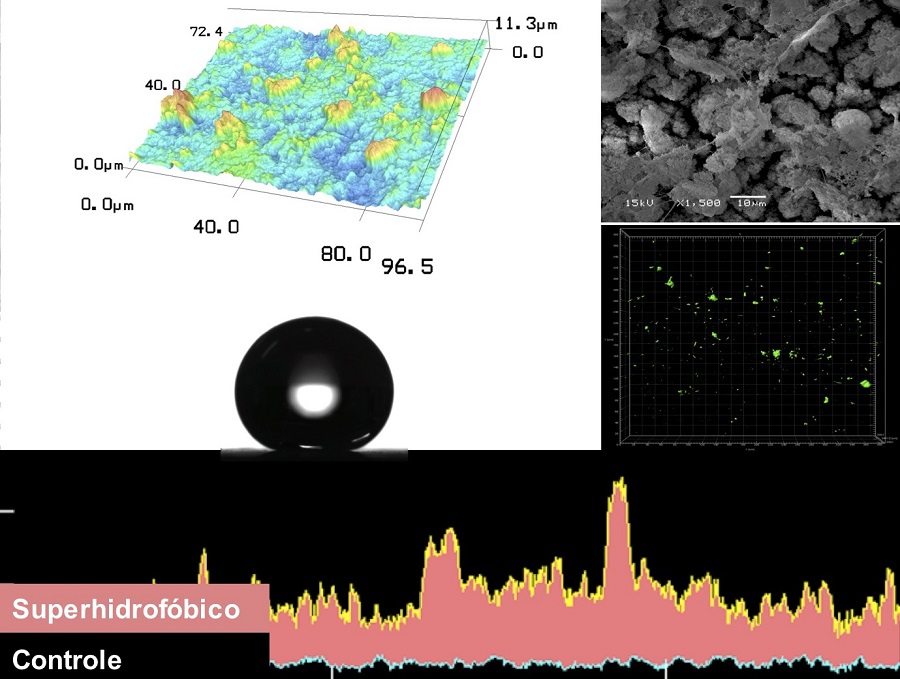

The main objective of the thesis, says Souza, was to develop a coating for titanium, a widely used material in dentistry, that has the ability to reduce microbial accumulation by using low-pressure plasma technology. Bibliographic searches have shown that a superhydrophobic surface would be a promising alternative to reduce the adhesion of bacteria to titanium and its alloys. A surface is considered to be superhydrophobic (that is, very difficult to wet) when the angle formed between it and a drop of water is greater than 150º. Superhydrophobicity, in turn, is based on high surface roughness and chemical composition.

“Based on this idea and previous studies already developed by Professor Barão’s research group, we aimed to develop a superhydrophobic coating with plasma technology, changing various parameters, such as pressure, gases, etc.” says Souza.

The coating was developed and characterized at the Laboratory of Technological Plasmas – UNESP – Sorocaba, which includes the Multi-User Laboratory for Characterization of Materials, under the guidance of Professor Elidiane Rangel. “Professor Elidiane has broad experience in the area and has been contributing extensively to our research group in the development of coatings for dental applicability,” explains Professor Barão.

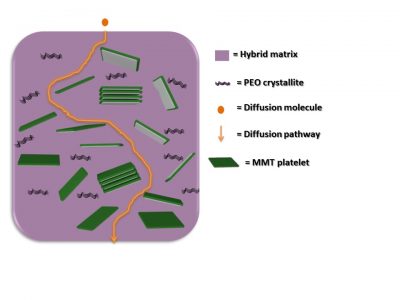

While the scientific literature recorded superhydrophobic coatings manufactured mainly in two stages (one to obtain roughness and the second to achieve hydrophobicity), Professor Rangel manufactured the coating in just one step, using the technique of PECVD (plasma-enhanced chemical vapor deposition). In this technique, an atmosphere of carefully selected gases is formed inside a reactor (in this case, oxygen, argon and hexamethyldisiloxane, of the formula C6H18OSi2). This atmosphere is highly energized (in a plasma state) after applying an electrical voltage, when the gases decompose and generate species (atoms, molecules, ions) with great propensity to react chemically. These species form new compounds that are deposited in a solid state on the surface of the material to be coated (in this case, titanium).

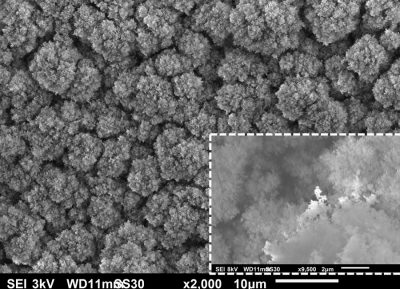

To manufacture the superhydrophobic coating using this technique, Professor Elidiane carried out a unique 60-minute process. The result was a surface based on silicon and oxygen, similar in appearance to cauliflower, with a different roughness. Making an analogy with the relief of our planet, the coating presented, on the micrometric scale, mountains of different heights and shapes, separated by valleys and canyons.

After obtaining the coating, in order to test its effectiveness as an antibiofilm, the study involved research groups from the University of Guarulhos and the University of Connecticut Health Center (USA), where the then doctoral student Souza carried out a doctoral internship.” In addition, the Brazilian National Nanotechnology Laboratory (LNNano) and the Brazilian Biosciences National Laboratory (LNBio) were used to characterize the coating and analyze the composition of adhered proteins, respectively.

The team of scientists then carried out a series of microbiological tests and analyses, both in the laboratory (in vitro) and in the mouth of volunteers (in situ), always comparing uncoated titanium and the titanium with the superhydrophobic coating. In one of the in vitro experiments, they used natural saliva as a culture medium for several microorganisms usually found in biofilms that grow on the implants. In contact with this medium, the coated titanium samples showed a very good antibiofilm performance with respect to the uncoated titanium: the adhesion of the set of microbes was eight times lower, and, in particular, the adhesion of a bacteria directly responsible for the formation of the biofilm matrix was 17 times smaller. Consequently, in a later stage of the experiment, biofilm formation in the coating was scarce and sparse.

In another interesting test, carried out in situ, four volunteers used a device on the palate during 3 days. This device was made with some untreated titanium discs and others with a superhydrophobic coating. When analyzing the composition of biofilms formed on the two surfaces, with the collaboration of professor Magda Feres of the University of Guarulhos, the researchers were once again surprised by the positive performance of the developed coating, which reduced by seven times the presence of pathogens directly associated with infections that lead to dental implant failures.