|

|||||||||||||||||||||

|

|||||||||||||||||||||

|

|

|||||||||||||||||||||

|

|||||||||||||||||||||

|

Graphene-based products are already being used by manufacturers, from heat-dissipating helmets to antistatic packaging. However, this wonderful material, as it is often called, still has much to deliver to society. As it is two-dimensional, flexible and excellent conductor of electricity, among other properties, graphene can be the basis of a series of high-performance miniaturized electronic and optoelectronic devices. However, this requires producing, at an industrial scale, a graphene whose network of atoms is free of unwanted impurities, but which contains, besides the carbon inherent in the graphene, small amounts of other elements (doping) in order to control its electronic properties.

In a work totally carried out in Brazil, a scientific team has proposed a process that can help produce large-scale graphene that is suitable for electronic devices. “The process developed in our group allows us to improve and adjust the graphene properties, as well as the removal of contaminants from its surface,” said Professor Claudio Radtke (UFRGS), corresponding author of an article reporting the study, recently published in The Journal of Physical Chemistry C.

The team acquired graphene samples produced by chemical vapor deposition (CVD) and transferred to silicon substrates. This technique is currently one of the most suitable for large-scale production of relatively large area graphene sheets, but it leaves residual impurities and generates defects in the graphene. To remove impurities, it is common to apply a heat treatment in an atmosphere of carbon dioxide (CO2), which is efficient in removing contaminants, but ends up generating new defects in the graphene sheet. The good news is that these defects can be neutralized (passivated).

While looking for strategies to passivate these defects, then PhD student Guilherme Koszeniewski Rolim found a scientific paper from 2011, which pointed to, through theoretical calculations, the possibility of using nitric oxide (NO) to passivate graphene defects with nitrogen atoms, while doping it to modulate its electronic properties (mainly transforming it into a semiconductor material, an essential condition for using graphene in electronic devices).

The team then decided to experimentally verify the theoretical prediction and, after performing the traditional treatment with CO2 at 500 °C, they applied a second heat treatment to the samples, this one in nitric oxide atmosphere and at different temperatures, from room temperature to 600 °C.

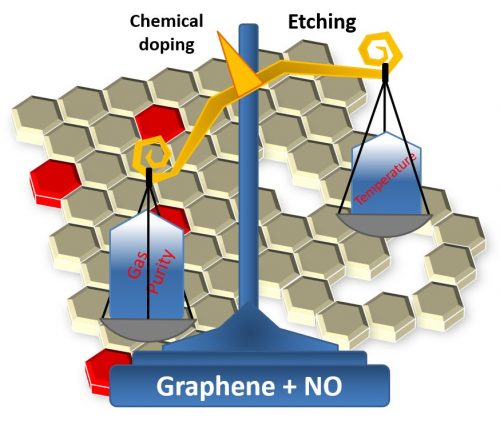

After the process, the researchers used various characterization techniques to check the results and gladly confirmed that nitrogen doping had taken place and that it had passivated the defects, thus improving the material’s electronic properties. However, the researchers also noted an unwanted effect of nitric oxide treatment: etching of graphene sheets at some points. After much scientific work, the team was able to determine the cause. During heating, there was a conversion of NO to NO2, which, as it is a much more reactive compound than the former, eventually oxidized the graphene.

However, the Brazilian team found a solution to this problem. The “eureka” moment occurred as the researchers were trying to determine the amount of nitrogen atoms that had been incorporated into graphene using a technique based on the analysis of nuclear reactions triggered by the effect of an ion beam on the graphene samples. In order to apply this technique, the team had to use an isotopically enriched nitric oxide in the heat treatment, which has a purity of 99.9999% instead of 99.9% of the gas previously used.

The analysis did not yield the expected results as it failed to quantify nitrogen, which was below the detection limit. However, the use of the enriched gas eventually brought great satisfaction to the team. Indeed, when the researchers compared the electronic properties of both sample types, they found that graphene treated with enriched gas always had superior properties. “Initially, such a result created much confusion in the interpretation of the results,” says Professor Radtke. “But after a few more experiments, it became one of the most important points of the article, highlighting the importance of gas purity during processing,” he adds. Specifically, the conclusion was that by properly controlling the temperature and purity of the gas during the treatment one can eliminate the problem of oxidative graphene degradation.

Thus, based on solid knowledge and scientific method, as well as some serendipity, the UFRGS team was able to develop a process of waste removal, defect neutralization and graphene doping, which improved the electronic properties of the material without producing deleterious side effects. Because it is a heat treatment in a gas atmosphere, a step that is now part of the industrial production of graphene, the process proposed by the Brazilian team could be easily applied in the production of graphene sheets for devices.

“The insertion of heteroatoms (such as nitrogen) into the graphene network without the degradation of its properties is especially important in the production of optoelectronic devices, high speed transistors, low power electronics and photovoltaic cells,” says Radtke, noting that manufacturing these graphene-based devices may be a reality in years to come. “The Graphene Flagship (European consortium of industries, universities and institutes) has announced the implementation of a pilot plant to integrate graphene at different production stages of devices as early as 2020,” comments the professor from UFRGS.

The study, which was funded by the Brazilian agencies CNPQ (mainly through INCTsNamitec and INES), Capes and Fapergs, was developed within the PhD in Microelectronics by Guilherme Koszeniewski Rolim, held at the UFRGS Graduate Program in Microelectronics and defended in 2018. The experimental work was carried out at the UFRGS Solid Surface and Interfaces Laboratory and the Brazilian National Synchrotron Light Laboratory.

[Paper: Chemical Doping and Etching of Graphene: Tuning the Effects of NO Annealing. G. K. Rolim, G. V. Soares, H. I. Boudinov, and C. Radtke. J. Phys. Chem. C, 2019, 123, 43, 26577-26582. https://doi.org/10.1021/acs.jpcc.9b02214.]

Forty-nine (49) proposals were submitted by the international scientific community within the XIX B-MRS Meeting + IUMRS ICEM symposium call. The number of submissions is one of the largest in the history of B-MRS events. “We received proposals from 18 different countries,” says Professor Gustavo Dalpian, chair of the event.

Forty-nine (49) proposals were submitted by the international scientific community within the XIX B-MRS Meeting + IUMRS ICEM symposium call. The number of submissions is one of the largest in the history of B-MRS events. “We received proposals from 18 different countries,” says Professor Gustavo Dalpian, chair of the event.

The organizing committee is already working on the analysis of the proposals, in order to solve cases of thematic overlap and to ensure the symposia are adequate to the structure of the event. When necessary, the committee will contact the authors of the proposals. The final list of symposia will be announced as soon as possible on the event website, B-MRS website, B-MRS Newsletter and social media. In February 2020, the abstract submission will be opened.

About the event

The event, which will be held from August 30 to September 3, 2020 at the Rafain Palace Hotel in Foz do Iguaçu (Brazil), will bring together the nineteenth edition of B-MRS annual meeting and the seventeenth edition of the international conference on electronic materials organized every two years by IUMRS.

In addition to symposia oral and poster presentations, the program will include plenary lectures by leading scientists such as Alex Zunger (University of Colorado Boulder, USA), Edson Leite (LNNano, Brazil), Hideo Hosono (Tokyo Institute of Technology, Japan), John Rogers (Northwestern University, USA), Luisa Torsi (Università degli Studi di Bari “A. Moro”, Italy) and Tao Deng (Shanghai Jiaotong University, China).

The event is coordinated by professors Gustavo Martini Dalpian (UFABC) in the general coordination, Carlos Cesar Bof Bufon (LNNANO) in the program coordination and Flavio Leandro de Souza (UFABC) as general secretary. At the international committee, the event features scientists from America, Asia, Europe and Oceania.

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

The Brazilian Materials Research Society (B-MRS/SBPMat) and the International Union of Materials Research Societies (IUMRS) invite the international scientific community to submit symposium proposals.

Until

Until October 31st NOVEMBER 18th 2019, the call for symposium proposals is open for the event that will bring together the XIX B-MRS Meeting (the annual B-MRS event) and the IUMRS – ICEM 2020 (seventeenth edition of the International Conference on Electronic Materials). The event will be held from August 30 to September 3, 2020 in Foz do Iguaçu (Brazil), a tourist town near the border with Argentina and Paraguay, which serves as a base for visits to the stunning Iguazu Falls and to others attractions in the surroundings.

Symposium proposals may be submitted by groups of researchers, preferably of international composition, who wish to organize a thematic symposium within the event. The conference will have a special focus on electronic materials due to the realization of IUMRS-ICEM. However, as in all editions of the B-MRS Meeting, the event will cover a wide range of materials science and technology topics. The organizers therefore welcome symposium proposals on topics relating to all types of materials, from synthesis to applications.

To submit a symposium proposal, simply fill out the online form available at http://sbpmat.org.br/proposed_symposium/.

The symposia will be the main focus of the event with plenary lectures, which will feature internationally renowned scientists such as Alex Zunger (University of Colorado Boulder, USA), Edson Leite (LNNano, Brazil), John Rogers (Northwestern University, USA) , Luisa Torsi (Università degli Studi di Bari “A. Moro”, Italy) and Tao Deng (Shanghai Jiaotong University, China).

Symposium proposals will be evaluated by the event committee, and by the end of 2019 the list of approved symposia will be released. In February 2020, the call for papers will be opened, which should be submitted within the scope of the thematic symposia. Symposium organizers will be responsible for evaluating the submitted abstracts and scheduling the symposium.

The joint event XIX B-MRS Meeting + IUMRS – ICEM 2020 is coordinated by professors Gustavo Martini Dalpian (UFABC) as the Conference Chair, Carlos Cesar Bof Bufon (LNNANO) as the Program Chair and Flavio Leandro de Souza (UFABC) as General Secretary. At the international committee, the event features scientists from America, Asia, Europe and Oceania.

The latest editions of the B-MRS Meeting brought together between 1,100 and 2,000 participants from various countries around the world, who presented their contributions within the symposia.

See the event website: https://www.sbpmat.org.br/19encontro/.

(Established by B-MRS in honor of Bernhard Gross, a pioneer of Brazilian materials research. It distinguishes the best oral and poster contributions presented by students in each symposium)

Symposium A

Symposium B

Symposium C

Symposium D

Symposium E

Symposium F

Symposium G

Symposium I

Symposium J

Symposium M

Symposium N

Symposium O

Symposium P

Symposium Q

Symposium R

Symposium S

Symposium U

Symposium V

Symposium X

(Sponsored by journals of ACS Publications, a division of the American Chemical Society. Prizes for the best student contributions of all the event)

ACS Publications Best Oral Presentation Prizes

ACS Publications Best Posters Prizes

(Sponsored by journals of the Royal Society of Chemistry. Prizes for the best student contributions of all the event)

On the occasion of the XVIII Meeting of the Brazilian Materials Research Society (B-MRS), which brought together about 1800 researchers from Brazil and more than a dozen other countries, from September 22 to 26, 2019, in Balneário Camboriú, Santa Catarina, Brazil, B-MRS executive board and council are publicly expressing their concern about the cuts and contingencies of funds for education and research in Brazil. If cuts in public universities and research and postgraduate funding bodies such as CAPES, CNPq and Finep persist, the country will be doomed to setback in its development process. We emphasize that the need to contain public spending due to the economic crisis does not justify the cuts in science and education, as these cuts are much larger – in percentage – than in other areas of government.

As the history of nations’ progress shows, the prosperity and well-being of population is directly related to a country’s ability to generate and absorb knowledge. It is unbelievable that in the 21st Century it is still necessary to justify investments in research and knowledge generation. Especially in an era of space travel, unprecedented longevity for mankind, and technologies like mobile phones that allow communication that a few decades ago was only in science fiction books.

We would like to address the Brazilian society that pays taxes to maintain the country’s science, technology and innovation system. With so much false news spread today, questions may arise about the intentions of the academic and university community. One might wonder if such a manifesto is not just a corporatist defense of an elite that sees its interests affected by policies adopted with cuts and contingencies. This is a legitimate question, but also one that can be firmly answered by the B-MRS community. Making science and developing new technologies presupposes the search for the truth, so we cannot shy away from alerting Brazilian society about the consequences of current policies of attacks on public universities and investment cuts.

Even if people don’t realize it everyday, their lives are highly dependent on technology: for energy and communication through mobile phones, access to medical treatments, availability of clean water and affordable food. There are many examples of Brazilian technology that benefit the Brazilian population and economy, such as the most obvious ones in which Brazil has world leadership: deepwater oil exploration, agribusiness and the production of medium-sized aircraft. On the other hand, the existence of laboratories and trained personnel, resulting from the investment in science and technology of many decades, allowed Brazil to quickly unravel the mechanisms of action of Zika virus, which causes microcephaly in infants. Thanks to this knowledge, the same virus brings hope of treatment for brain tumors that today have no chance of cure. Mention should also be made of the need for training qualified professionals who can serve the population, which can only be achieved with a thriving university system that includes research.

The academic community must have a responsibility not to be an alarmist. However, it also has a duty to alert the Brazilian people to some of the effects that the destruction of our science, technology and innovation system will have – inevitable if policies of cuts persist. Worldwide, the largest contribution of resources to science and technology is made by the state; companies generally account for the cost of applied research, built on the basic knowledge acquired in more fundamental studies. It is important to remember that the destruction of this system can be much faster than the decades required to build it.

We want to close this manifesto with a note of hope. In one of the lectures at the XVIII SBPMat Meeting, one of the achievements that makes Brazilian science proud was presented: the Sirius particle accelerator, installed at the National Center for Energy and Materials Research, in Campinas. Built with 85% national technology, Sirius is among the most advanced in the world, and can enable the generation of knowledge essential for many strategic areas for the Brazilian economy. The creation of Sirius is yet another demonstration of the capacity of the Brazilian scientific community, which we hope can continue its work. This will only be possible, however, if there is a change in policies for education and research in Brazil.

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

|

|

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

|