A captivating group of materials whose existence has been experimentally proven a little over a decade ago will feature on the afternoon of September 25 at the XVIII B-MRS Meeting. These are topological insulators, which in broad lines can be described as materials that are insulating in their interior but can support flows of electrons on their surface. These materials have attracted the scientific community both for the challenges they pose to basic science and for their application possibilities in quantum computing and spintronics, two areas that should generate technologies for the very high performance devices we will use in the future.

The lecturer will be Mingzhong Wu, Professor of Physics at Colorado State University (USA). Prof. Wu received his Ph.D. in Solid State Electronics from Huazhong University of Science and Technology (China) in 1999. In 2007 he joined the faculty of Colorado State University. Between 2012 and 2016 he was an Editor for IEEE Magnetics Letters. Currently he serves as an Editor for Physics Letters A, besides being on editorial boards of Journal of Applied Physics and Journal of Magnetism and Magnetic Materials. He has authored about 140 papers and 4 book chapters, and he has co-edited a book on magnetic insulators.

In his plenary lecture at the XVIII B-MRS Meeting, Professor Wu will talk about the experiments he conducted on a system consisting of a topological insulator layer interfacing with a magnetic insulator layer. Working with this system, Professor Wu could understand a little more about the nature of topological insulators, as well as explore applications related to the control of magnetic properties.

See our mini interview with this scientist.

B-MRS Newsletter: – We´d like to know more about your scientific work. Please choose your favorite contribution, briefly describe it, and share the references.

The main interests of my research group are with magnetization dynamics and spintronics. We have contributed to the development of the research field of insulator-based spintronics. We explored different approaches for using magnetic insulators to generate pure spin currents; demonstrated the use of spin currents to manipulate and control magnetization in magnetic insulator thin films; and developed unique processes for the growth and patterning of high-quality magnetic insulator thin films. Using spin waves in magnetic insulator thin films, we have observed experimentally a number of new nonlinear phenomena, such as soliton fractals and chaotic solitons. These observations contributed to the advance of “Nonlinear Dynamics” in general and the understanding of magnetization dynamics in magnetic thin films in particular. Some of our works are listed at: https://www.physics.colostate.edu/about/people/mingzhong-wu/

B-MRS Newsletter: – What does the word “topological” refer to in the case of the insulators you study?

The word “topological” refers to the topological distinction between topological insulators and ordinary insulators. Insulators can be characterized by a Z2 topological invariant. This invariant takes odd integers for topological insulators but takes even integers for ordinary insulators.

For more information on this speaker and the plenary talk he will deliver at the XVIII B-MRS Meeting, click on the speaker’s photo and the title of the lecture here https://www.sbpmat.org.br/18encontro/#lectures.

Due to the high participation in the

Due to the high participation in the

A mix of entrepreneurial spirit, born in childhood, and scientific training, developed in the university stage, led Brazilian Amanda Luizetto dos Santos to create

A mix of entrepreneurial spirit, born in childhood, and scientific training, developed in the university stage, led Brazilian Amanda Luizetto dos Santos to create

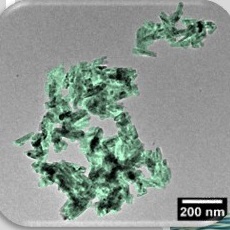

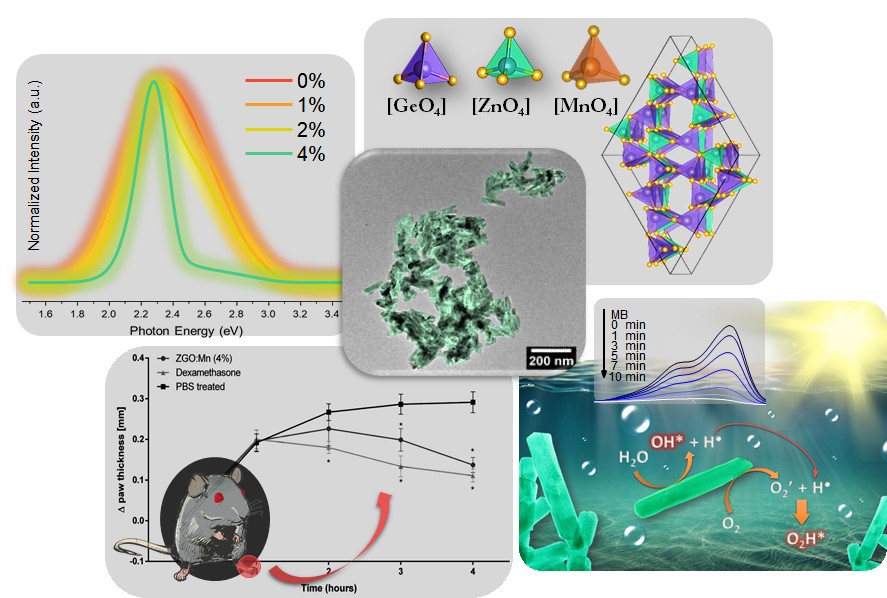

A team of researchers from Brazilian universities found, in cylindrical nanostructures known as nanorods, an anti-inflammatory effect equivalent to that achieved by commercial drugs. Researchers have also demonstrated the effectiveness of these nanorods as catalysts (accelerators) in the degradation of a pollutant. These applications are even more relevant considering that the scientific team was able to produce large quantities of the material through a simple and fast process. The work carried out shows the potential of these nanorods for the development of new medicines and for the treatment of effluents.

A team of researchers from Brazilian universities found, in cylindrical nanostructures known as nanorods, an anti-inflammatory effect equivalent to that achieved by commercial drugs. Researchers have also demonstrated the effectiveness of these nanorods as catalysts (accelerators) in the degradation of a pollutant. These applications are even more relevant considering that the scientific team was able to produce large quantities of the material through a simple and fast process. The work carried out shows the potential of these nanorods for the development of new medicines and for the treatment of effluents.

The Royal Society of Chemistry (RSC) has prepared an online collection of articles by Brazilian authors in celebration of the

The Royal Society of Chemistry (RSC) has prepared an online collection of articles by Brazilian authors in celebration of the