Sorry, this entry is only available in Brazilian Portuguese.

Category: News

Former B-MRS president Osvaldo Novais de Oliveira Junior is the author of a text about Brazilian science published in Folha de São Paulo

Professor Osvaldo Novais de Oliveira Junior (IFSC-USP), member and former president of SBPMat, is the author of a text published in Folha de São Paulo, one of the main Brazilian newspapers, on the blog ‘Darwin e Deus’ (column by science journalist Reinaldo José Lopes) about the success and impact of Brazilian science. In the text, the professor describes three types of knowledge resulting from science and highlights the importance of increasing the number of scientists and professionals trained in research environments in order to meet the demands of the Brazilian population.

Here follows the text:

The greatest proof of the success of Brazilian science is at the Planalto Palace. Were it not for the excellence of Brazilian medicine, the result of decades of scientific work, today there would be another President of the Republic.

Without the competence of the doctors of Juiz de Fora who promptly attended the then candidate after the stabbing episode, as well as the doctors in São Paulo who performed the other surgeries, President Bolsonaro, even if he survived, would not have recovered so quickly to the point of working normally shortly after the attack.

In my opinion, the connection between facts that change the direction of the country and Brazilian science does not seem to have been made as of yet. This is probably so because the effect of the different forms of knowledge that science creates has not been analyzed in detail.

Doing science generates three types of knowledge. The most visible and tangible is the knowledge that generates, in a relatively short time, technology and solutions for humanity. It is the knowledge transferred from scientists to technology innovators, which in the 21st Century has been accomplished mostly by the great technological powers, that is, the United States, China and other Asian countries, and some countries in Europe. Here, the majority term is essential, as it is not enough to have quality science and technology, as knowledge transfer only occurs effectively when there is a volume of research, products and solutions.

The two other types of knowledge are less visible to society in general. One is the knowledge derived from the curiosity and perseverance of humans in understanding how the universe works, without concern if there will be any practical application. Often, the application exists, but it will only become evident long after such knowledge has been generated. Perhaps the most emblematic example today is Einstein’s theory of relativity. It was created with an abstract conception, incomprehensible even for scientists of the time, to explain the phenomena of nature that had no correlation with people’s daily lives.

As far as I know, Einstein never suggested the possibility of a direct application to his theory. Well, the Theory of Relativity is now essential for positioning systems (GPS). Without taking into account the Theory of Relativity, determining the position of a person or object on Earth would be wrong for about 10 km with the errors accumulated in a week of GPS operation. In short, without the Theory of Relativity there would be no GPS or the navigation systems we use in our daily lives.

The third type of knowledge has so little visibility that it is confused with the result of university education. It is knowledge that does not lead directly to new technologies, but serves to absorb and adapt technologies, develop local solutions and allow high-level functioning of systems that depend on technology. This type of knowledge is incorporated by qualified professionals trained at research universities.

What is not always understood is that professionals with this level of skill and competence can only be trained in an environment where science is done. In medicine, to stay on the initial example, the incorporation and improvement of new technologies are usually done by doctors with sophisticated training, with postgraduate degrees and active participation in research programs conducted at universities of excellence.

For those who consider this third type of knowledge is of little relevance, I emphasize that countries with better quality of life and higher development rates are not on the list of those that generate more technology. I refer to Scandinavian countries and others like Switzerland and Luxembourg, which, due to the size of their population, are not large enough to generate a lot of technology – compared to the largest technology-producing countries. However, without any exception, all these countries with high quality of life have high density in generating knowledge of the third type, with excellent science.

And Brazil? Our country has outstanding examples of knowledge generation of the first type, with science providing competitive technology worldwide in sectors such as aeronautics, oil extraction in deep waters and agribusiness. Other sectors have created relevant technologies, albeit with less economic impact.

Unfortunately, despite the quality of science carried out in these sectors, density is low and we generate very little technology when the dimensions of the country and its population are taken into account. This is explained by the small size of our scientific system. Despite the great advance in recent decades, the number of scientists per inhabitant is still much smaller than that of developed countries. In this regard, Brazil does not appear on the list of the 20 best ranked countries.

A similar situation occurs in knowledge oriented to the development of local solutions, which I classified as a third type. Brazil trains excellent professionals at its research universities, which in turn incorporate new technologies and create solutions for society in many areas. This results in the country’s excellence in areas such as medicine and health, engineering, agriculture and livestock, and in many other areas.

Again, we have the density problem: the number of trained professionals, and their role in generating knowledge, is insufficient to benefit the entire Brazilian population. This insufficiency is at the root of our inequality, since the extremely low productivity at work depends essentially on the good functioning of technologies that demand knowledge of this third type, in which the supply of trained professionals is insufficient.

In short, the problem in Brazil is not low quality of science that is done here, but the low density of scientists and professionals trained to meet the demands of society. In addition to bringing the erroneous perception of lack of quality, the low density in fact makes it difficult (when not preventing) a country to achieve excellence in topics that require concentrated efforts of great importance. It is not for any other reason that Brazil is competitive in technologies, such as those already mentioned, in which there is a density of trained researchers, based on public policies initiated decades ago.

I expect our leaders, at all levels, will realize the direct and indirect benefits of a robust and quality scientific system. Even if it is for their survival in the event they need adequate health care. But mainly to fulfill the dream of transforming Brazil into a less unequal country.

B-MRS Newsletter. Year 7, issue 2.

|

||||||||||||||||||||

|

||||||||||||||||||||

|

Featured paper: Nanomembrane microtubes and hybrid materials for advanced electronic devices.

Some of the challenges of the next generation of smartphones, sensors and other electronic devices can be solved with the help of nanomembrane microtubes (sheets made from various materials with nanometric thicknesses and micrometric lateral dimensions, which can be self-rolled and form microtubes).

In the city of Campinas (São Paulo State), at the Brazilian Nanotechnology National Laboratory of the National Center for Research in Energy and Materials (LNNano / CNPEM), a group of scientists has developed expertise in processes for the synthesis, manufacture and characterization of nanomembranes and their applications. In papers published in January and February of this year in the journals Nano Letters and Nature Communications, the authors explore some nanomembrane potentials, mainly related to their flexibility and dimensions, to develop new memristors and transistors – two widely used electronic devices.

More precisely, the LNNano researchers show that nanomembrane microtubes can be key parts in the manufacture of promising components using organic and hybrid materials (organic-inorganic) such as memristors and transistors. Thus, the novelties proposed in the articles can contribute to the development of even smaller, flexible, portable, cheaper devices and equipment that combine better performance and more low energy consumption features.

In an interview with the B-MRS Newsletter, Carlos Cesar Bof Bufon, corresponding author of both articles, talks about the scientific, technological and social impact of the research and about the skills and infrastructure involved in carrying it out. Bufon is a researcher and head of the Devices Division at LNNano/CNPEM.

B-MRS Newsletter: The articles present advances, developed at LNNano, in technologies for electronic devices (transistors and memristors). In your opinion, what are the main technological and/or scientific contributions of these articles?

Carlos Cesar Bof Bufon: The work entitled “Ambipolar Resistive Switching in an Ultrathin Surface-Supported Metal–Organic Framework Vertical Heterojunction” published in Nano Letters (DOI: 10.1021/acs.nanolett.9b04355), reports the development of a new type of memristor using structures called Surface-Supported Metal-Organic Frameworks (SURMOFs). SURMOFs are hybrid structures composed of metallic ions connected by organic ligands. The structure is highly organized on surfaces covered with chemically active self-assembled monolayers (SAMs). There are more than 70 thousand types of metal-organic structures (MOFs) that can be prepared as SURMOFs to confer new features to electronic devices. In addition to the unique properties, its considerable mechanical flexibility and low cost arouse interest in the scientific community for applications. However, in the case of a hybrid material consisting of organic and inorganic elements, the integration of this class of nanomaterials becomes a technological challenge. To circumvent this limitation, this work presents a new architecture for the integration of these SURMOFs structures for the development of a new type of memristor. The proposed architecture is based on the upper electrical contact of SURMOF HKUST-1 ultrathin films using self-rolled metal nanomembranes (microtubes). The SURMOF films explored in this work have thicknesses of the order of 20 nanometers. This new architecture opens up promising paths in the area of electronic devices based on SURMOFs, as well as providing a technological platform for conducting studies not yet reported in the literature for this class of materials. For example, the investigation of how electrical charges are conducted in layers of ultrathin SURMOFs.

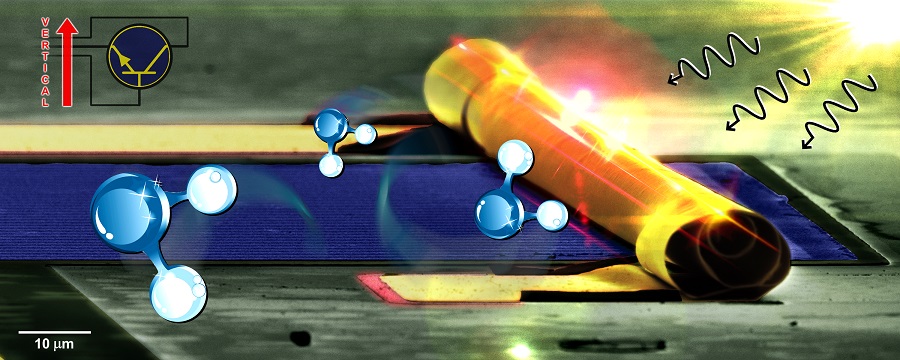

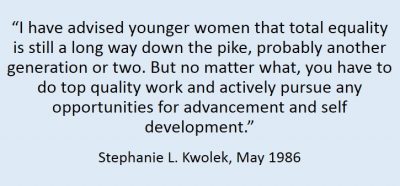

The work entitled “Edge-driven nanomembrane-based vertical organic transistors showing a multi-sensing capability” published in Nature Communications (doi: 10.1038/s41467-020-14661-x) presents the development of a vertical organic transistor platform. Transistors are the main components for electronic circuits and processors. Compared to inorganic transistors, the organic ones have the advantages of low-cost and easy fabrication, which makes them attractive for flexible electronic devices in several areas. A significant advantage of vertical transistors is their easy integration with light-emitting devices and photodetectors in the formation of integrated optoelectronic systems. The devices presented in this work were processed entirely using conventional microfabrication and photolithography techniques, which is an advantage of technological feasibility. One of the main differences of these new transistors is related to the use of self-rolled metallic nanomembranes as drain electrodes, thus promoting the formation of a smooth mechanical contact with the organic semiconductor layer. In this architecture, the organic semiconductor layer can reach thicknesses below 50 nanometers. The manufactured devices showed high current densities (~ 0.5 A / cm2) with low operating voltages (≤ 3 V). Based on our theoretical study, it was possible to predict an improvement in the structure of the transistor, resulting in projections of devices with current densities of up to 10 A / cm2. Such values, obtained at low operating voltages on a platform composed of active organic layers, highlights the potential of these devices to be integrated with flexible and portable electronic applications in the future. Besides, the new transistors were able to detect different levels of humidity and light, thanks to the device platform based on self-rolled nanomembranes. Therefore, the developed transistors also have great potential for advancing next-generation sensor technology.

Scanning electron microscopy image (artificially colored) of the vertical organic transistor based on rolled nanomembrane (yellow tones). The incident radiation and the water molecules (artificially placed) illustrate the multiple sensitivity characteristics of the new electronic device.

B-MRS Newsletter: How could the results of the articles impact people’s daily lives (social impact)? Do you think that the proposed technologies could replace those currently used or create new applications? If so, what would be the advantages of these new technologies developed at LNNano? Would it still need many steps to bring the results of the articles to the market?

Carlos Cesar Bof Bufon: Memristor is considered one of the four fundamental electronic components. On a computer, it is capable of performing information processing and storage functions. In this work, the behavior of a memristor was observed in conditions of high relative humidity (between 90-70%). Analogous to a sponge, the water molecules present in the environment are absorbed by SURMOF nanopores. In a given electric field, these molecules facilitate the conduction of electrons within the material by changing its electrical resistance. The difference in electrical resistance can reach 1 million times using low operating voltages, less than 2 V. In a practical application, this difference can correspond to the binary states 0 and 1. The total fabrication of the device was carried out with conventional techniques photolithography, compatible with industrial scale production. The fact that it depends on the humidity for its operation does not limit its commercial application, as this can be easily bypassed through encapsulation processes, common in the electronic device industry.

The manufacture of organic transistors in vertical architecture using curled nanomembranes as drain electrodes allows the reduction of the region of interest to less than 50 nanometers (more than a thousand times less than the thickness of a hair). This implies a significant advance in the electronics industry, because the portability of electronic applications, such as smartphones, computers and televisions, depends on the reduction in the number and size of transistors. The mechanism of operation of the device reported in this work expands the current understanding of vertical organic transistors, showing that current densities can be improved by performing careful manipulations in the spatial structure of the intermediate metallic electrode (source). Besides, the preparation of transistor microchips was carried out using microfabrication techniques compatible with the industrial scale. Thus, these devices can be easily integrated into electronic applications with a few additional steps, such as encapsulating microchips, to prevent degradation of organic materials.

The two concepts of devices based on nanomembranes expand the possibilities for the use of hybrid materials in electronics. As much as there is a tendency to substitute one technology for another, the concepts developed in our works seek to open new frontiers and possibilities through the design of functional structures from their fundamental elements such as atoms and molecules.

All the technologies that we develop in the area of devices at LNNano/CNPEM are firmly grounded in two focus: the understanding of the fundamental concepts that govern the properties of the components, and their technological application. These two papers started fundamentally from scratch. In terms of technology readiness level (TRL), the devices have reached the functional validation of the components in the laboratory environment. Within the TRL scale, we achieved the fourth level out of a total of 9 – the latter being commercialization. It is also worth mentioning that the next level of development must involve the participation of the productive sector, which is who can accelerate the research towards the market.

B-MRS Newsletter: Briefly tell us the story of the works reported in the two articles: how and when the idea came up, whether it was necessary to gather very different skills, the infrastructure used, curiosities etc.

Carlos Cesar Bof Bufon: The works are the result of different stories, but were developed in the same research group sharing the idea of exploring the potential of nanomembranes in the area of functional devices. This theme is part of my Young Researcher project financed in 2016 by FAPESP. The idea of applying SURMOFs as a memristor, using nanomembranes as the top contact, was developed together with the post-doctorate Dr. Luiz Gustavo Simão Albano. Our research group started evaluating the feasibility of using SURMOFs as functional materials in devices about 3 years ago. Since then, the group has been continuously establishing the implementation of synthesis and integration routes for applications in the areas of electronic components. The work was carried out entirely at LNNano/CNPEM, and has a list of co-authors who actively contributed to making this work possible: Tatiana P. Vello (growth of SURMOFs), Davi HS de Camargo (manufacture of devices and illustrations), Ricardo ML da Silva (device manufacturing), Dr. Antonio CM Padilha (DFT simulations) and Prof. Dr. Adalberto Fazzio (DFT simulations).

The work with the transistor follows the same pattern as the memristor – a combination of functional materials and nanomembranes. About 15 years ago, I became interested in the potential of using nanostructured layers as fundamental blocks in vertical electronics. Once I was aware of the work of Prof. Ivo Humlegem, from UFPR (died 2018), in the area of vertical transistors, a series of advantages and challenges caught my attention. The idea of the work came by anticipating that an improvement of the performance of vertical transistors could be achieved with the use of a drain electrode based on nanomembrane combined with a patterned intermediate electrode (source) using photolithography. In May 2018, Dr. Ali Nawaz (a former student of Prof. Ivo!), started the execution of the project at LNNano/CNPEM. Being a complex project, the advanced infrastructures for processing and characterizing LNNano/CNPEM devices were essential. And like the memristor, the research depended on a set of varied expertise. During the project, Dr. Leandro Merces provided critical assistance in the investigation of the theoretical aspects of the devices, while collaborators Davi Camargo (specialist in microfabrication) and Denise de Andrade (graduate trainee at the State University of Ponta Grossa), provided the entire work the necessary technical support.

[Papers: Ambipolar Resistive Switching in an Ultrathin Surface-Supported Metal–Organic Framework Vertical Heterojunction. Luiz G. S. Albano, Tatiana P. Vello, Davi H. S. de Camargo, Ricardo M. L. da Silva, Antonio C. M. Padilha, Adalberto Fazzio, Carlos C. B. Bufon. Nano Lett. 2020, 20, 2, 1080-1088. https://doi.org/10.1021/acs.nanolett.9b04355 and Edge-driven nanomembrane-based vertical organic transistors showing a multi-sensing capability. Ali Nawaz, Leandro Merces, Denise M. de Andrade, Davi H. S. de Camargo & Carlos C. Bof Bufon. Nature Communications volume 11, Article number: 841 (2020). https://www.nature.com/articles/s41467-020-14661-x ].

From idea to product: Kevlar, the strength of a scientific discovery.

The bulletproof vests that protect police and military personnel around the world, the cords that held the Pathfinder spacecraft on its descent to the surface of Mars, and the gloves worn by workers in the metalworking industry. What do they have in common?

The answer is Kevlar®, a highly durable polymeric synthetic fiber that combines high strength and low weight (it is five times more resistant than steel per weight module). The fiber can be used as a raw material for cords or flexible and comfortable fabrics. Also, it can be added to other materials to reinforce them. Kevlar® generates products capable of resisting the most diverse aggressions, from shrapnel and stab wounds to firearm shots. Also resistant to extreme temperature and pressure conditions, the fiber has been in the desert, on the mountain, in Antarctica, on the seabed and in space.

The history of this material begins, of course, with a scientific discovery that was made in 1965 in one of the DuPont laboratories by Stephanie Louise Kwolek. Stephanie had a bachelor’s degree in chemistry, without a doctorate and was the only female representative in the laboratory. Her competence and passion found in this place and at that moment a favorable environment, which yielded good results, not only for the company, but also for humanity as a whole.

From walks in the woods to DuPont laboratories

Stephanie Kwolek was born on July 31, 1923 in the United States, the daughter of Polish immigrants. Together with her parents and younger brother, her childhood was in New Kensington, a small town 30 km from Pittsburg, Pennsylvania, in a wooded area she used to walk with her father while trying to discover animals and identify plant species, whose leaves were pasted and classified in a notebook. Her father deceased when she was only 10 years old, but he was responsible for developing a strong curiosity and taste for experimentation in Stephanie. With her mother, who until her father’s death spent much of her time at home in front of the sewing machine (later she started working in the industry to support the family), Stephanie developed her creativity and taste for fashion. The girl loved making paper clothes for her paper dolls.

After fantasizing about a career as a fashion designer, Stephanie Kwolek discovered that she wanted to be a doctor. However, as medical school was very expensive, she went to study science at Carnegie Mellon University in Pittsburg. More precisely, she attended Margaret Morrison Carnegie College, which was a college for women within that university. During her university years, in addition to an excellent academic performance, Stephanie gathered laboratory experience, doing work for the university and for companies during her summer vacations.

Stephanie graduated in 1946, at the age of 23, with a “major” in chemistry and a “minor” in biology, and went on to look for a job in the field, thinking about working for a few years until she collected the money to start her medical course. Stephanie was quickly hired by DuPont – by then already famous for the invention of nylon, the first synthetic fiber in history, among other products. The young woman then moved to Buffalo, New York, to work as a chemist in the Rayon Department, which would later become the Pioneer Textile Research Laboratory, where she worked with the synthesis of new polyamides and polyesters.

In 1950, the laboratory was transferred to the company’s main “invention site,” the so-called Experimental Station, located in Wilmington, Delaware, where Stephanie moved to in order to contribute with the team that would try to develop new methods of polymer production, performed at low temperatures, to create fibers with the highest possible resistance.

Passionate about the laboratory

By that time, Stephanie had already traded her dream of being a doctor for the passion of being a scientist. It fascinated her to have a new challenge each day and to learn something new every day. Furthermore, the working environment in that DuPont laboratory was very positive for her.

To begin with, the job was stable and there was a certain freedom to choose the research topics, within a list that the director prepared based on the company’s objectives. (Stephanie always liked participating in two projects simultaneously, preferably one that was more fundamental and the other one more applied). To develop her research, Stephanie could work independently, following her own plans, and without the pressure to generate immediate economic results. She just needed to have good sense to know when to stop a project that would not bear fruit in the medium term. This possibility of independent and free research was important not only to satisfy the researcher’s creative and curious nature, but also because she was working on very new lines of research, still lacking fundamental research, which needed to be done within the laboratories of the company.

In addition, there was great equipment and many opportunities to exchange ideas with colleagues. Finally, Stephanie was able to publish her results in articles or books, after the texts were reviewed by professionals from various sectors of the company, who checked whether the publication of that data could harm business. For Stephanie, writing articles was an important moment in her work, when ideas became more organized and results were subjected to scrutiny.

In her view, the set of good working conditions generated a conducive medium for scientific discoveries capable of generating radical innovations (new materials or molecules and new synthesis processes) that could position the company at the forefront of the market. As was the case with Kevlar®.

In her view, the set of good working conditions generated a conducive medium for scientific discoveries capable of generating radical innovations (new materials or molecules and new synthesis processes) that could position the company at the forefront of the market. As was the case with Kevlar®.

The discovery that spawned Kevlar®

In the 1960s, the Pioneer Research Laboratory in Textile Fibers became involved in the search for a fiber being very resistant, but also very light. One of DuPont’s goals was to offer the market a material that would replace steel as a rubber additive in tire manufacturing, so as to make tires lighter and thus reduce fuel use, as a period of oil shortage was expected in the following years.

After experimenting with dozens of different polymers, the laboratory decided to start working with the group of polyaramides, or aromatic polyamides, which were promising in terms of properties, but also famous among researchers for the difficulty of dealing with them in the laboratory. The polyaramides were particularly difficult to dissolve due to the rigidity of their rod-shaped molecules, unlike the flexibility of many other polymer molecules.

Persistent, as well as competent, Stephanie Kwolek was cast to participate in the challenge. Or, rather, the challenges, in the plural, that arose daily in each of the stages involved: the choice and synthesis of the compounds that would react to form the polymer (which, at the time, did not readily exist for sale), the polymerization method and, not least, the dissolution of the polymer obtained. In fact, to form the polymer fiber desired by DuPont, it was necessary to spin the polymer. For this, the laboratory had a very simple equipment, called a spinneret, in which a polymeric solution is forced to pass through small holes. In the next step, the solvent is removed and the fibers obtained.

At this stage of development, Stephanie was testing different compounds to dissolve the difficult polyamides, when she looked at her freshly prepared polymer solution and noticed, with the naked eye, that it was essentially different from all the others she had ever seen. The new solution was opaque and fluid, and not transparent and viscous as expected. In addition, when stirred, it was opalescent (with reflections in the colors of the rainbow).

Instead of throwing it down the drain, she got excited and took it to the spinneret to perform the spinning test. Believing that the milky aspect was due to the presence of particles in suspension that could clog the holes of the spinneret, the equipment technician refused to do the test. The spinning was done a few days later, after Stephanie scientifically proved that there were no particles in the solution. And the result was remarkable. The polyamide fibers obtained with the recipe developed by Stephanie were much more resistant than nylon, and also more resistant than steel, but much lighter. As soon as she confirmed the results of the characterization of the new material, she presented her discovery to her superiors, who joined her enthusiasm.

But what is the explanation for the super strength of polyamide fibers? Here’s the thing. Stephanie Kwolek managed to temper a polyaramide and with it prepare a polymeric solution of rigid macromolecules. During the spinning process, these molecules remained fully stretched and aligned in an orderly fashion. The result was a fiber with a very organized structure, from which the exceptional properties emerged.

The solution she had placed in the spinneret, the scientist would later discover, could be classified as a liquid crystalline solution. From this discovery, several new high-performance fibers were created based on liquid crystalline solutions, mainly Kevlar®.

The solution she had placed in the spinneret, the scientist would later discover, could be classified as a liquid crystalline solution. From this discovery, several new high-performance fibers were created based on liquid crystalline solutions, mainly Kevlar®.

Product and market development

The development of the Kevlar® product, which started immediately after Stephanie’s discovery in 1965, took several years within DuPont, and involved an interdisciplinary team without the direct participation of Stephanie, who remained in the laboratory in search of new discoveries. The process included the development of the final chemical formula and adjustments to the spinning equipment. The adaptation to the industrial scale took into account economic, practical and ecological issues. In addition, starting in 1972, a marketing plan for Kevlar® was designed and put into practice, based on partnerships with potential customers to customize the product according to the desired application, generating an entire family of fibers.

Thus, it was in 1982 that the product was actually marketed, seventeen years and hundreds of millions of dollars after the initial scientific discovery. Since then, the Kevlar® family has conquered dozens of markets through hundreds of products, such as firemen boots, coatings for armored cars, rackets and components for boats, airplanes and automobiles, to name just a few examples besides those mentioned in the beginning of this story.

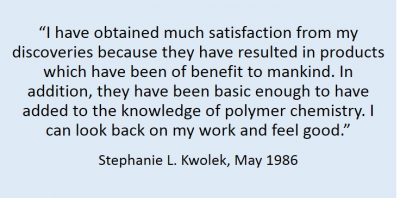

As for Stephanie Kwolek, she continued to work at DuPont until her retirement in 1986. She won several awards and honors for her work with liquid crystal solutions. She became a female icon of scientific discovery and “the face” of Kevlar®. After leaving the company, she dedicated time to encouraging girls to work in research, in addition to advising DuPont. She died at the age of 90, in June 2014, in Wilmington.

Some references:

- Stephanie L. Kwolek, interview by Raymond C. Ferguson in Sharpley, Delaware, 4 May 1986 (Philadelphia: Chemical Heritage Foundation, Oral History Transcript # 0028). Available here.

- Stephanie L. Kwolek, interview by Bernadette Bensaude-Vincent at Wilmington Delaware, 21 March 1998 (Philadelphia: Chemical Heritage Foundation, Oral History Transcript #0168).

- Women in Chemistry: Stephanie Kwolek. Canal no YouTube do Science History Institute. Available here.

- The Kevlar Story – an Advanced Materials Case Study. David Tanner, James A. Fitzgerald, and Brian R. Phillips. Angew. Chem. Int. Ed. Engl. Adv. Mater. 28 (1989) No. 5.

- Kevlar Technical Guide. Available here.

(Português) SBPMat endossa nota da SBPC em defesa da democracia.

B-MRS member receives award from TMS (USA)

Professor Victor Carlos Pandolfelli (DEMa-UFSCar), a B-MRS member, received an award from TMS (The Minerals, Metals and Materials Society, USA) as co-author of the work “Improving the reliability of fluidized bed calciners by suitable refractory lining selection,” presented in 2019 at this society’s annual meeting. The award, whose name is “Light Metals Subject Award – Alumina/Bauxite” is dedicated to research that highlights the application of science in solving practical problems. The award ceremony took place on February 24, 2020, during the 149th TMS Annual Meeting, which was held in San Diego, California (USA).

The award-winning work, coordinated by Pandolfelli, was carried out within a joint project between the company 4 Cast, specialized in ceramic materials for high temperature applications, and UFSCar. Mariana A. L. Braulio (4Cast), J. R. Cunha (Alcoa Alumar – Brazil) and D. Whiteman (Alcoa- Australia) also received the award as co-authors of the work.

New B-MRS Board of Directors took office at a ceremony.

The new board of directors of the Brazilian Materials Research Society (B-MRS) took office on the morning of February 14, in a ceremony held in the auditorium of the Gleb Wataghin Institute of Physics at Unicamp (IFGW – Unicamp), in the city of Campinas (São Paulo state), with the presence of more than 80 people.

Elected by the members of B-MRS in October 2019 for the February 2020 to February 2022 term, the new board is chaired by Prof. Mônica Alonso Cotta (IFGW-Unicamp), who became the first female president of B-MRS.

Another characteristic of this board is the broad representation in geographical terms (directors from the south, southeast, northeast and north Brazilian regions), disciplinary terms (backgrounds in Physics, Chemistry and Materials Engineering) and gender (four men and three women).

Along with the president, Rubem Luis Sommer (CBPF) assumed his duties as director of administration, finance and patrimony, as well as five scientific directors: Prof. Andrea Simone Stucchi de Camargo (IFSC-USP), Prof. Antonio Eduardo Martinelli (UFRN), Prof. Iêda Maria Garcia dos Santos (UFPB), Prof. Ivan Helmuth Bechtold (UFSC) and Prof. Newton Martins Barbosa Neto (UFPA).

In her speech, the president highlighted the interdisciplinary nature of the materials research community and, in particular, that of B-MRS. “One of our strengths derives precisely from the synergy between the areas, and this requires good communication skills between researchers, respecting complementary expertise, sharing knowledge, to obtain a product that is greater than the sum of its parts,” said Cotta, who added that communication with the lay public will be one of the fronts that the new board will focus on as a priority.

In addition, Professor Cotta highlighted the importance of the scientific community in taking a stand against political decisions with no scientific basis that can affect the lives of millions of people. “B-MRS will continue to support the excellent work that the Brazilian Society for the Advancement of Science and the Brazilian Academy of Sciences have lead in recent years, working with Congress in a purposeful and meaningful way, and demonstrating strong defense of Brazilian research and science,” she added. See full speech here.

Professor Cotta received this position from her predecessor, Prof. Osvaldo Novais de Oliveira Junior (IFSC-USP), who chaired B-MRS for two consecutive terms. The former president, who received praise for his management in the speeches of the authorities, expressed words of gratitude to the B-MRS team, to the directors and members of the deliberative council that accompanied him, and to the B-MRS members who participated in the actions of the society. “I am sure that the next years will be even better,” she said.

Speeches given by the authorities: economic-social development and women in science

The ceremony, which lasted a little over an hour, also included the words of Unicamp authorities (the vice-chancellor, Prof. Teresa Dib Zambon Atvars, and the director of the IFGW-Unicamp, Prof. Pascoal José Giglio Pagliuso) and the representatives of several entities: Brigadier Maurício Pazini Brandão, from the Brazilian Ministry of Science, Technology, Innovations and Communications (MCTIC); Prof. Marcia Cristina Bernardes Barbosa, director of the Brazilian Academy of Sciences (ABC); Prof. Carola Dobrigkeit Chinellato, board member of the Brazilian Physics Society (SBF); Prof. Antonio José Roque da Silva, director of the Brazilian National Center for Research in Energy and Materials (CNPEM); Prof. Ronald Cintra Shellard, director of the Brazilian Center for Research in Physics (CBPF), and Elson Longo (CDMF-UFSCar), who was president of B-MRS in the 2004-2005 biennium.

In the brief speeches given, some of the constant subjects were the conquest of spaces by women, the need to unite different individuals and organizations for the survival and advancement of science and technology, and the seriousness and impact of the research developed in Brazilian universities. One of the most discussed subjects was the transformation of scientific knowledge into wealth, not only as a desire or need, but also as a fact of the current Brazilian reality, which can be observed mainly in startups and companies resulting from universities and research centers.

The first speaker was Brigadier Maurício Pazini Brandão, professor at the Technological Institute of Aeronautics (ITA), who participated in the ceremony as regional director of the representative office of MCTIC in São Paulo. In his words, he stressed that the materials research community must go beyond the production of scientific articles. “We want products and innovation with invoices,” he said.

Then, the vice-chancellor of Unicamp returned to the question raised by Brandão, with some data on companies founded by former students of that university. Together, these “daughter companies” have an annual turnover of R$ 7.9 million, equivalent to three times the annual budget of Unicamp, informed Professor Atvars, who ended the brief speech highlighting the achievements of women, often obtained by means of “triple shift work.” More examples of companies and innovations from the academic world, in the area of ceramic tiles and cosmetic products, were presented later in the speech by Professor Elson Longo.

Professor Pascoal José Giglio Pagliuso spoke about Professor Mônica Cotta, his colleague at the teaching staff and the IFGW board, where she is the associate director. The IFGW director described the new B-MRS president as tireless, vigilant, with a huge heart and a prominent position in matters involving minorities and human rights. “She is the first woman and the first professor at Unicamp to occupy this impactful position in Brazilian research,” he highlighted.

Afterwards, Marcia Barbosa, professor at UFRGS and director at ABC, took up the issue of transforming knowledge into wealth and affirmed that basic science does in fact generate development. A scientist with outstanding performance in favor of the participation of women in the exact sciences, Barbosa said she was concerned with the present times and called on the scientific community to all work “together.” “The new B-MRS board will know how to build windmills to transform the energy of tsunami and gather together other entities,”she said. Work in partnership was also highlighted in the words of Professor Carola Dobrigkeit Chinellato (Unicamp), who hoped that the new board will make new bonds and extend the scope of B-MRS.

In the penultimate speech of the ceremony, Antonio José Roque da Silva, who directs Sirius (construction of the new Brazilian synchrotron light source), commented on the budgetary difficulties he has faced to carry out the project, sometimes linked to the difficulty of politicians and society in general in understanding the times and actors involved in scientific research and its transformation into social development and wealth. “We need to better explain this time scale,” he urged.

Concluding the speches, Ronald Cintra Shellard brought some data that show the imbalance, in Brazil, between the research carried out in the universities (where there is more freedom to choose a theme) and in the research institutes (in which the scientific work aims to fulfill a determined mission). The ratio of university/institute researchers, which in the world ranges from 1/1 to 4/1, in Brazil it is 12/1, said the director of CBPF. According to the scientist, this does not reflect an excess of professionals at the university, but a lack of researchers in the country, particularly in research institutes.

B-MRS Newsletter. Year 7, issue 1.

|

|||||||||||||||||||||

|

|||||||||||||||||||||

|

Featured scientists: Interviews with winners of the Brazilian award for best doctoral theses.

The Capes Thesis Award distinguishes, annually, the best doctoral theses of each area, defended during the precedent year within Brazilian graduate programs. On December 12, 2019, 49 awards and 98 honorable mentions were bestowed by Capes to recently graduated doctors, among 1.142 applications.

Capes is the Brazilian federal government agency under the Ministry of Education, responsible for quality of undergraduate and postgraduate courses in Brazil.

Meet some of the winners from the materials research community.

Interview with Miguel Henrique Boratto, winner of the Capes Award in Materials area.

Thesis: Semiconducting and insulating oxides applied to electronic devices. Available at https://repositorio.unesp.br/handle/11449/153215

Author: Miguel Henrique Boratto.

Supervisor: Luis Vicente de Andrade Scalvi (UNESP).

Improving performance and reducing the cost of electronic devices that are part of our daily lives is the desire of almost everyone. However, contributing to this is a not a reality for everyone. Miguel Henrique Boratto, dedicated the four years of his doctorate and the two years of his master’s degree to study some materials from the oxide group, with a view to their possible use in the production of fundamental pieces of electronics.

With a degree in Physics and a master’s and doctorate in Materials Science and Technology from UNESP (the São Paulo State University), Miguel first studied this group of materials during his master’s degree, but it was in his doctorate that he managed to manufacture thin films of tin, titanium and zirconium oxides using inexpensive processes, and testing their performance in electronic devices (transistors, capacitors and memristors), always guided by professor Luis Vicente de Andrade Scalvi.

The work that generated the awarded thesis was carried out in laboratories at UNESP in the cities of Bauru and Araraquara, and also at The University of Western Ontario (Canada), where Miguel did a 12-month internship, under the supervision of professors Giovanni Fanchini and Lyudmila Goncharova. During his doctorate, Miguel received fellowships from Brazilian agencies Capes (in Brazil) and CNPq (in Canada).

Five scientific articles directly related to the thesis were published in peer reviewed international journals with good impact factor. In addition, the results presented by Miguel at the 2017 B-MRS Meeting were awarded with two awards for the best oral presentation and best poster of their symposium.

After defending his doctorate, Miguel continued studying materials for electronic applications, as a postdoctoral fellow at UFSC. In addition, in June/July last year, he was selected to be part of a group of 580 young scientists from 89 countries participating in physics discussions with 30 Nobel Prize laureates, the 69th Lindau Nobel Laureate Meeting. Currently, as a post-doc fellow, he researches organic devices for bioelectronic applications at UNESP – Bauru and teaches Modern Physics Laboratory.

See our brief interview with Miguel Boratto, 32 years old, born in São João da Boa Vista (São Paulo).

B-MRS Newsletter: In your view, what is the most relevant contribution (scientific/technological/social) of the awarded thesis?

Miguel Boratto: In and of itself, the thesis presents a good part of the work developed and published, that’s why I think this is the most relevant work I have produced. Among the works presented, scientific relevance is in obtaining, by means of low cost methods, known materials followed by their applications in electronic devices to study their properties and final performance.

B-MRS Newsletter: From your point of view, what are the main factors that allowed you to carry out a prominent research work at the national level?

Miguel Boratto: Aid from the national program “Science without Borders,” with CNPq scholarship for internship abroad, greatly expanded my horizon in relation to the work to be developed and partnerships to be carried out. I also think the partnerships I have made are important, as they are necessary to carry out work with more resources and possibilities.

B-MRS Newsletter: Leave a message for our readers who are undergraduate or graduate students.

Miguel Boratto: The epigraph of my thesis, by Niels Bohr: “An expert is a man who has made all the mistakes which can be made in a very narrow field.”

Interview with Heloísa Pimenta de Macedo, winner of the honorable mention in Materials area.

Thesis: Hybrid Porous Ceramics Derived from Polysiloxanes Containing Ni Nanoparticles for Production of Methane via Hydrogenation of CO2. Available at https://repositorio.ufrn.

Author: Heloísa Pimenta de Macedo.

Supervisor: Dulce Maria de Araújo Melo (UFRN).

Co-supervisor: Michaela Wilhelm (Universität Bremen).

When she started her doctorate in Materials at the Brazilian Federal University of Rio Grande do Norte (UFRN), under the guidance of Professor Dulce Maria de Araújo Melo, Heloísa Pimenta Macedo was already familiar with ceramic materials and their applications in catalysts – themes in which she had worked during her Materials Engineering degree and her Master’s in Materials, always at UFRN. However, it was in her doctorate that she had the opportunity to investigate superior properties to those she already knew, and to contribute to a relatively new research area.

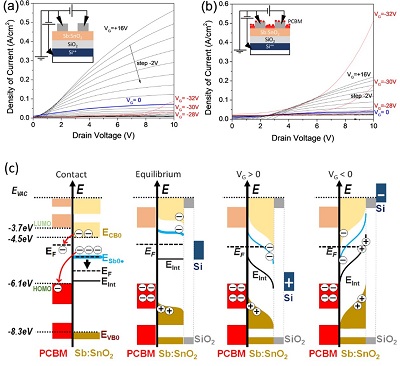

The theme of Heloísa’s doctorate was the development of hybrid ceramics, their characterization and their application as catalysts in a process of converting carbon dioxide (CO2), the great villain of the greenhouse effect, into methane (CH4), a compound with added value that can be used as fuel or raw material.

Hybrid ceramics have the distinctiveness of being obtained through the pyrolysis of polymeric compounds. They are polymers that convert into ceramics after going through high temperatures (400 to 600 °C, in Heloísa’s work). In addition, to work as catalysts, these ceramics can be added with metals (in this case, nickel nanoparticles).

Heloísa completed her doctorate with a Capes scholarship, and it was this same Brazilian agency that awarded her a scholarship to do a one-year internship at Universität Bremen (Germany), in a group with equipment and skills in the subjects she was researching.

The work of Heloísa’s doctorate was reported in an article published in a peer reviewed international journal with good impact factor. In addition, during her doctorate, Heloísa participated in some research projects that resulted in a series of published papers.

See our brief interview with this 30-year-old researcher from Natal (Rio Grande do Norte state), who is currently conducting research as a postdoctoral fellow at the UFRN Environmental Technology Laboratory.

B-MRS newsletter: In your view, what is the most relevant contribution (scientific/technological/social) of the awarded thesis?

Heloísa de Macedo: The development of hybrid ceramics with a wide variety of easily adjustable properties, featuring promising materials for important catalytic reactions, such as the conversion of CO2 into CH4.

B-MRS newsletter: From your point of view, what are the main factors that allowed you to carry out a prominent research work at the national level?

Heloísa de Macedo: To be part of a modern laboratory (Environmental Technology Laboratory) and of an excellent Postgraduate Program (with maximum score according to Capes), offered me all the resources for developing the thesis. In addition, of course, of the opportunity to undertake a doctoral internship at an excellent university in Germany, with renowned professionals in the field of materials, and all the infrastructure and equipment available, which allowed me to do high quality work.

B-MRS newsletter: Leave a message for our readers who are undergraduate or graduate students.

Heloísa de Macedo: I would tell them to persist in their dreams and believe in their potential, as they are the fundamental parts for Brazilian science.

Interview with Bernardo Jordão Moreira Sarruf, winner of a honorable mention in the area of Engineering.

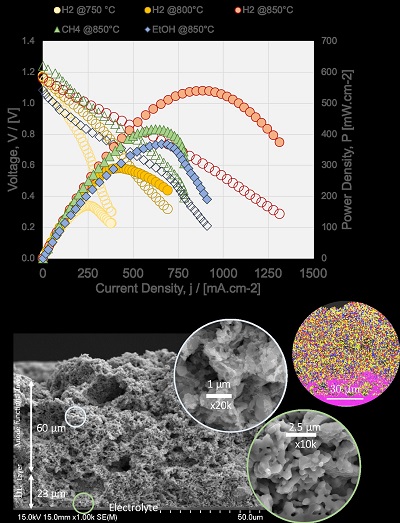

Thesis: Ceria-based anodes with cobalt and copper additions for the direct utilization of methane in solid oxide fuel cells. Available at https://www.researchgate.net/publication/338789167_BernardoSarruf-PhDThesis2018?channel=doi&linkId=5e2a4e8b299bf15216787c23&showFulltext=true

Author: Bernardo Jordão Moreira Sarruf.

Supervisor: Paulo Emílio Valadão de Miranda (UFRJ).

In his doctoral research, Bernardo Jordão Moreira Sarruf made a contribution to the development of fuel cells which is particularly relevant to the Brazilian reality. Fuel cells are devices that generate electricity and which have increased in popularity in recent years due to the emergence of some electric car models based on this technology. In fact, fuel cells are capable of transforming the chemical energy of a compound (the fuel) into electrical energy, through electrochemical reactions of oxidation and reduction. They work similarly to ordinary batteries, with the difference that the compounds that undergo the reactions come from outside the device.

The most common fuel in these batteries is currently hydrogen. However, this element, although it is the most abundant in the universe, is not easily obtained on planet Earth, and even less so in gas stations in Brazil. The good news is that other compounds can be used as fuel for fuel cells. Such is the case of methane (the main component of vehicular natural gas) and ethanol – two fuels widely available in the country.

In his doctoral research, Bernardo Sarruf developed a material based on cerium dioxide that performed very well on fuel cells “fueled” with methane, ethanol and hydrogen. The material was used as a battery electrode, that is, as a propellant for the transformation of chemical energy into electrical energy.

Bernardo’s first leap into the subject of fuel cells was in 2008, during his undergraduate degree in Materials Engineering at Brazilian Federal University of Rio de Janeiro (UFRJ), when he performed undergraduate research under the guidance of Professor Paulo Emílio Valadão de Miranda at the Hydrogen Laboratory. Between 2011 and 2013, when carrying out the master’s degree with the same advisor and in the same laboratory, Bernardo went deeper into the microstructural characterization of fuel cell anodes, while developing a software company for characterizing materials that he had just incubated in the university startups incubator.

Then, in 2013, Bernardo started his doctorate, once again under the guidance of Paulo de Miranda. From 2015 to 2016, he undertook an internship at the University of Birmingham (England), under the supervision of Professor Robert Steinberger-Wilckens, in a research center dedicated to fuel cells and their various fuels. In 2018, Bernardo defended the doctoral thesis that earned him the honorable mention in the Capes Thesis Award. The work generated five articles published in peer-reviewed international journals with good impact factor. During his doctorate, Bernardo received a scholarship from Brazilian agencies Capes (in Brazil) and CNPq (in England).

See our brief interview with Bernardo Sarruf, born in Niterói (Rio de Janeiro state), 33 years of age, who continues to work in the area of fuel cells at the Hydrogen Laboratory as a postdoctoral researcher, in addition to being a collaborating professor at the university.

B-MRS newsletter: In your view, what is the most relevant contribution (scientific/technological/social) of the awarded thesis?

Bernardo Sarruf: The fact that the work has demonstrated the development, even if embryonic, of a material that showed excellent results operating as an anode in solid oxide fuel cells for the use of both hydrogen and primary fuels, such as methane and ethanol, paves the way for inserting the fuel cells during the energy transition we are currently undergoing. A fuel cell is a device that combines hydrogen and oxygen from the air to produce electricity, with water as the electrochemical reaction by-product. In our case, instead of using hydrogen (which is still expensive and has an incipient supply infrastructure), we use methane (natural gas) or ethanol, products that already have a well-developed supply chain. As well known, policies to mitigate climate effects will increasingly consist of giving priority to low carbon technologies, which is the case with hydrogen chain technologies. Using ethanol as a fuel in an electrochemical device with almost zero CO2 emissions opens up even more opportunities for Brazil, which is currently the second largest exporter of this product.

B-MRS newsletter: From your point of view, what are the main factors that allowed you to carry out research work that is highlighted at the national level?

Bernardo Sarruf: The support of funding agencies (CAPES and CNPq) is and was fundamental, and we hope that research in Brazil will receive more and more the attention it deserves. The experience of my supervisors in the area was extremely important. I can say that I had a unique opportunity to work with cutting-edge resources and equipment, which were mostly acquired with the support of Hydrogen Laboratory projects over the years.

B-MRS newsletter: Leave a message for our readers who are undergraduate or graduate students.

Bernardo Sarruf: An important message is, perhaps a cliché: there is no magic recipe or shortcuts, if you wake up every day anxious to “get your hands dirty” and go to work, follow the experiment, cheer with the achievements and learn from mistakes, you will surely succeed. Moreover, what I try to do in my day-to-day life as a researcher is seeing beyond what is obvious to me; listening to people outside the professional environment also helps a lot in this task.

Interview with Fábio de Oliveira Braga, winner of a honorable mention in the area of Engineering.

Thesis: Optimized configuration of multilayer ballistic shielding with frontal ceramic and aramid composites or curauá fabric.

Author: Fábio de Oliveira Braga.

Supervisor: Sérgio Neves Monteiro (IME).

The bulletproof vests that offer highest levels of protection to police and military personnel in Brazil are reinforced with extremely resistant synthetic fabrics, which can be used in the form of thick plates, about 3 cm thick, or combined with ceramic plates. With these reinforcements, ballistic vests are able to protect a person from the firing of a 7.62 mm caliber rifle, for example.

Throughout his master’s and doctorate, conducted at the Brazilian Military Engineering Institute (IME) under the guidance of Professor Sérgio Neves Monteiro and with CNPq fellowships, Fábio de Oliveira Braga investigated whether it was possible to replace these synthetic fabrics with materials based on natural fibers, thus reducing the weight, thickness and cost of the reinforcement plates of the ballistic vests. In particular, Fábio has been dedicated to studying the fibers that are extracted from the leaves of an Amazonian plant belonging to the pineapple family, the curauá. These fibers can withstand high tensions – property that the Indians of the region have long used to make nets, to tie boats, etc.

Fábio’s doctoral research, awarded with the Capes Award, was entirely carried out in Brazil. At IME, Fábio prepared the samples, performed the physical and mechanical tests and applied a statistical method to find the best thickness ratio between ceramics, curauá and a third material (aluminum) in the composition of the vest plates. Thermogravimetric analyses were performed at the Institute of Macromolecules of the Brazilian Federal University of Rio de Janeiro. In addition, he used the facilities of the Army Assessment Center to perform ballistic tests, which showed that plates made with materials based on curauá are capable of absorbing energy from an impact that could be lethal to humans, in addition to retaining the projectile.

Seven scientific articles related to the thesis were published in peer-reviewed international journals with good impact factor.

In addition, the work won an award at the poster competition of a symposium on sustainable materials engineering at the annual meeting of the The Minerals, Metals and Materials Society, held in 2019 in the U.S.A.

See our brief interview with Fábio Braga, born in Resende (Rio de Janeiro state), metallurgical and materials engineer with a specialization in Inspection and Maintenance Engineering in the Petroleum Industry, and a master’s and doctorate in Materials Science.

Currently 30 years old, Fábio is a professor at Universidade Federal Fluminense (UFF) and at Faculdade SENAI Rio, where he coordinates the specialization courses in Welding Engineering and Equipment and Materials Inspection Engineering.

B-MRS newsletter: In your view, what is the most relevant contribution (scientific/technological/social) of the awarded thesis?

Fábio Braga: In the research line I was inserted in, we sought to replace aramid composites (such as Kevlar®) in ballistic vest plates, with lighter, sustainable, inexpensive and widely available composites made with natural lignocellulosic fibers. In my work, a commercial blanket of natural fiber from the Amazon, known as curauá, was used for the first time, integrating these ballistic plates. In order to maximize the performance of the material and minimize its weight, a statistical method of multivariate analysis was used to approach the problem. In the end, we obtained optimized material properties.

B-MRS newsletter: From your point of view, briefly, what are the main factors that allowed you to carry out a prominent research work at the national level?

Fábio Braga: I attribute the success of this work to the quality of the scientific training I had in Engineering and Materials Science, at State University of the North of Rio de Janeiro (UENF) as undergraduate student and at IME (master’s and doctorate). I had the opportunity to receive fellowships for undergraduate research (UENF) for 3 years, master and doctorate, which was fundamental. In addition, I had great emotional and financial support from my family, wife (Bianca) and my advisor, Professor Sergio Neves Monteiro, who was instrumental in my training.

B-MRS newsletter: Leave a message for our readers who are undergraduate or graduate students.

Fábio Braga: Research requires much dedication and study, but it is a very rewarding path. Today I live from teaching and doing research, and I am very grateful to have chosen this path.