In several Brazilian universities, multidisciplinary scientific teams are currently working to deliver to society, in the shortest possible time, solutions to help combat COVID-19. Beyond generating publications, and even knowledge, the main objective of these works is to save lives.

The materials research community is actively participating in some of these challenges, which could generate important solutions such as rapid, reliable diagnostic tests and virucidal materials for ventilator valves, as well as personal protective equipment (PPEs) produced in Brazil.

In the early afternoon of May 7, in its first live transmission, B-MRS brought together four researchers who are working on these challenges. These scientists told an audience of about 100 how they organized to respond to this emergency situation, and what may be the social impact of their projects. The reports showed the importance of continuous investment in research and collaboration between individuals and institutions.

The discussion was mediated by Carlos César Bof Bufon, researcher and head of the Devices Division at the Brazilian Nanotechnology Laboratory (LNNano/CNPEM). Bufon is part of the organizing committee of the next annual B-MRS event, the XIX B-MRS Meeting.

The online discussion panel, broadcasted on B-MRS’s Zoom platform and Facebook, was held within the Brazilian Virtual March for Science, an event promoted by Brazilian Society for the Progress of Science (SBPC) with the aim of calling attention to the importance of science.

National tests for COVID-19 diagnosis and detection of antibodies.

The scientists Mariana Roesch Ely (professor at the University of Caxias do Sul, UCS) and Talita Mazon (researcher at CTI Renato Archer) talked about their respective works to develop sensors for COVID-19 diagnostic tests, which they are carrying out with the support of specialists in the Chemistry, Electronics, Informatics, Physics, Materials, Biology and Health areas.

Both sensors are point-of-care instruments. This expression designates miniaturized devices that allow performing tests anywhere, without the need for laboratories or other equipment, and receiving the result within a few minutes.

According to the researchers, the sensors they are developing will be able to detect those infected with COVID-19 within the first day of infection – a characteristic that none of the diagnostic techniques currently used in the country allows. Finally, they said that the new sensors will provide more accurate results (with fewer false negatives or positives) than many of the rapid tests that are currently available on the market.

In both works, the development of the sensors is quite advanced. However, the two scientists concur in stating that 6 months is a reasonable time for a product to be ready, tested with respect to the RT-PCR method (the most reliable at the moment) and viable at an industrial scale.

In her statement, Professor Mariana said that since 2012 she has been working on developing sensors based on magnetoelastic technology, initially aimed at the detection of bacteria and yeasts. When Brazil experienced the outbreak of the Zika virus in 2015, the scientist and her entire research network directed their work towards this virus, gaining experience in detecting this type of organisms, which are much smaller than bacteria. According to Professor Mariana Roesch Ely, the magnetoelastic sensor would be able to detect both the viral particle (from the beginning of the infection) and the antibodies produced by the person who is or has been infected. Thus, it could be an important tool to define measures and protocols in all phases of the pandemic, including the resumption of face-to-face economic activities.

Researcher Talita Mazon said that she has worked five years on integrating ceramic and biological materials to develop point-of-care sensors, which, in her view, are well adapted to the Brazilian reality, given that a large part of the population lives far away from laboratories and hospitals. With the experience accumulated during that time, the scientist was able to finalize in 2019, together with a multidisciplinary team, an electrochemical sensor that detects the Zika virus accurately and within a few minutes. She is currently adapting this platform to detect Sars-COV-2 (the virus that causes the COVID-19 disease).

Thinking about the possibility of producing the sensor without the need for imported inputs, mainly at an industrial scale, the researcher looked for local partners and adapted the sensor to the biological inputs that could be produced in Brazil. In addition, she is establishing a partnership with the public microelectronics company CEITEC, located in the state of Rio Grande do Sul, whose installed capacity would allow it to manufacture the chips for all the sensors needed to test the Brazilian population in the next phases of the pandemic. “We have to join forces to develop solutions that can actually be met by the country’s industrial capacity,” said Professor Talita Mazon.

Virucidal materials for masks and respirators

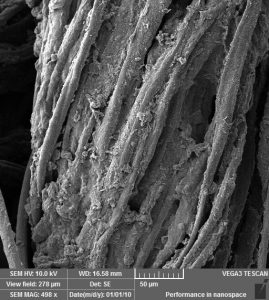

In the panel, Dachamir Hotza, professor at the Federal University of Santa Catarina (UFSC), told of the individual and group efforts carried out to bring responses to society during the COVID-19 pandemic. In one of these works, the researcher and his collaborators are carrying out the physical and biochemical characterization of masks used in hospitals in order to define precisely when the masks lose their functionality and need to be replaced. In addition, working with other institutions and a regional company he previously collaborated with, the researcher is advancing in the development of fabrics with virucidal activity. One difficulty that has not yet been overcome, said the researcher, was accessing a laboratory that has the appropriate level of biosafety procedures to perform tests with the new coronavirus.

Active materials in the elimination of the Sars-COV-2 virus were also addressed by Professor Petrus Santa Cruz, from the Federal University of Pernambuco (UFPE). The scientist told how he accumulated knowledge generated over decades, available in articles and patents from his research group, for his work related to fighting the pandemic. One example relates to an emergency action aimed at providing the public health system with respirator valves that could be used in patients infected with COVID-19 in a phase prior to intubation, given situations of high occupancy rates of ICU beds and mechanical ventilators. Professor Petrus’ interdisciplinary team, which includes software experts, was able to overcome the challenge of manufacturing these valves on 3D printers with the necessary surface roughness to prevent the bacterial adherence (initially bacteria and, probably, also viruses). In addition, the group is working to give this and other materials an active role in eliminating the virus, using nanotechnology to break through the wall that protects the viral RNA.

Continuous investments for fast results

The four panelists highlighted that the capacity of science to quickly respond to society in times of emergency is the result of many years of efforts and investments. “There is no on/off button for science, because it is made up of the accumulation of knowledge,” said Professor Petrus.

On the other hand, with successive cuts to the CTI budget, many Brazilian researchers have developed strategies to circumvent the difficulties and continue working. It is a characteristic of the Brazilian scientist to adapt to adverse situations, commented Professor Dachamir.

The panelists’ statements showed that a combination of expertise and persistence, on the one hand, and creativity and reinvention, on the other, is part of the method they are applying in their work related to fighting the pandemic.

Another aspect the scientists highlighted as fundamental to the success of emergency projects was the work in multidisciplinary collaborative networks, including with companies that could produce solutions at an industrial scale. “This is the time to intersect everyone’s expertise to give a quick response to society,” said Professor Mariana Roesch Ely.