Sorry, this entry is only available in Brazilian Portuguese.

Category: News

B-MRS and IUMRS announce new schedule and plenary sessions for the joint event to be held in 2021.

The Brazilian Materials Research Society (B-MRS) and the International Union of Materials Research Societies (IUMRS) announce the new schedule and confirm the plenary speakers of the joint event XIX B-MRS Meeting + IUMRS ICEM. Due to the Covid-19 pandemic, the joint event, which would be held this year, was postponed to be held from August 29 to September 2, 2021. The venue will be maintained: the Rafain Palace Hotel and Conventions, located in Foz do Iguaçu (PR, Brazil).

The Brazilian Materials Research Society (B-MRS) and the International Union of Materials Research Societies (IUMRS) announce the new schedule and confirm the plenary speakers of the joint event XIX B-MRS Meeting + IUMRS ICEM. Due to the Covid-19 pandemic, the joint event, which would be held this year, was postponed to be held from August 29 to September 2, 2021. The venue will be maintained: the Rafain Palace Hotel and Conventions, located in Foz do Iguaçu (PR, Brazil).

The new call for thematic symposium proposals starts on May 4 and ends on November 2, 2020. The symposium organizers who submitted proposals in 2019 will be able to again submit them in this new call. In addition, the system will be open to receive new proposals, which should be prepared by groups of researchers, preferably composed of international researchers, on topics related to any type of materials, from synthesis to applications (including electronic materials, which are the focus of IUMRS ICEM).

To submit a symposium proposal, simply complete the online form on the event website. The symposium proposals will be evaluated by the event committee, and, the list of approved symposia will be released between the end of 2020 and the beginning of 2021. The submission of abstracts for presentation within the symposia will remain open from February 1st to April 11th, 2021. The symposium organizers will be responsible for the evaluation of the submitted abstracts and for the symposium program.

The symposia will be the main axis of the event along with the plenary lectures, which will feature internationally renowned scientists, such as Alex Zunger (University of Colorado Boulder, USA), Edson Leite (LNNano, Brazil), Hideo Hosono (TokyoInstitute of Technology, Japan), John Rogers (Northwestern University, USA), Luisa Torsi (Università degli Studi di Bari “A. Moro”, Italy), Tao Deng (Shanghai Jiaotong University, China) and Thuc-Quyen Nguyen (University of California Santa Barbara, USA). The traditional memorial lecture of the B-MRS Meeting will be given by professor Cid Bartolomeu de Araújo (UFPE, Brazil). All speakers have confirmed their presence at the event.

The organizing committee of XIX B-MRS Meeting + IUMRS – ICEM 2021 is formed by professor Gustavo Martini Dalpian (UFABC) as conference chair, Carlos Cesar Bof Bufon (LNNANO) as program chair, and Flavio Leandro de Souza (UFABC) in the general secretary. In the international committee, the event has scientists from America, Asia, Europe and Oceania.

Event website: https://www.B-MRS .org.br/19encontro/

Featured scientist: Edson Roberto Leite.

Edson Roberto Leite memories related to science are all very pleasant: the book about rockets in his childhood in the interior of São Paulo, the opportunity to use an exceptional microscope during the sabbatical period in the United States, the discovery of a mechanism for the growth of nanocrystals at the Brazilian National Synchrotron Light Laboratory…

Some of these wonderful memories include the many occasions experienced alongside his tutor and scientific father, Professor José Arana Varela, a prominent Brazilian materials scientist who died in 2016. Arana Varela was honored by B-MRS with the creation, in 2019, of an award that bears his name, and which annually distinguishes a prominent researcher from Brazil, who gives a plenary lecture at the Society’s annual event. In its first edition, the award was befittingly granted to Edson Roberto Leite, professor at the Federal University of São Carlos (UFSCar) and scientific director of the Brazilian National Nanotechnology Laboratory (LNNano-CNPEM). Leite is also editor for Latin America of the Journal of Nanoparticle Research (Springer).

Edson Roberto Leite received his first degree in Materials Engineering from UFSCar in 1988. In doubt between pursuing a career in industry or academia, he initially tried to reconcile both. After graduating, he worked in the research and development area at 3M, while doing his master’s degree and starting his doctorate, both in Materials Science and Engineering at UFSCar. In 1992, he left the company in order to dedicate his time to the doctorate, a decision that he recalls did not please his father-in-law, who was concerned with the livelihood of the family that by now included two children. However, over the years, the results of this decision have been very positive. In 1994, shortly after defending his doctorate, Leite became a professor in the Chemistry Department at UFSCar and started a career as a researcher in materials, which would not only be fruitful, but also enjoyable.

Co-author of more than 400 scientific articles published with more than 19 thousand citations, today Leite has an h index of 72 (Google Scholar). The scientist is also the editor of three books related to materials for energy and co-author of a book on the process of nucleation and growth of nanocrystals. Leite received several awards, including the Scopus Prize from Elsevier/CAPES (2006), for the excellence of his scientific production as a whole, and the John Simon Guggenheim Memorial Foundation Fellowship (2009), awarded to scientists with exceptional research skills. In 2012, Edson Leite was elected member of the World Academy of Ceramics and the Academy of Sciences of the State of São Paulo. In 2014, he was cochair of the Spring Meeting of Materials Research Society, held in San Frascisco (USA). In 2019 he was elected full member of the Brazilian Academy of Sciences (ABC).

Read our interview and learn more about this scientist, his main contributions and his memories of Professor Arana Varela.

B-MRS newsletter: At school, you had more affinity with science subjects, right? Do you remember how this taste for science originated?

Edson Roberto Leite: A person’s story always has the personal version and the version of the people who interacted with him. I will recount my perspective of how it happened.

At school I always had a strong affinity for Science and History. A striking memory was when I was in the third grade of elementary school and my father took me to the Municipal Library of Araras to take out a membership card so I could access books. The first book I chose was about rockets. I have always loved the conquest of space and the science behind fundamental historical moments. It is noteworthy that man had reached the moon only a few years earlier, nuclear power was seen as the global energy solution and semiconductors were just beginning.

In addition to this fond memory, there were other motivations, including Jonny Quest, a really cool cartoon. This animation, in addition to the adventures, had a lot of science fiction, and Jonny’s father (Dr. Benton Quest) was a renowned scientist with an excellent research laboratory in his own home.

My childhood, then, was always marked by a strong influence of science classes. I think it easily guided me to choose Engineering. At first the idea was to become a mechanical engineer, but during my prep course for the entrance exam I was introduced to Materials Engineering, at UFSCar. I took the exam in the middle of 1983 and passed. From then on I knew what I wanted and what I liked.

However, there was still a doubt, whether to go to the academic area or go to industry (my father was a Nestlé employee in Araras and the industrial sector always caught my attention). During my undergraduate studies, I went to live at the student housing headed by Celso V. Santilli (today an important researcher in the field of Materials, Professor at IQ-UNESP-Araraquara) and he helped me to participate in an undergraduate research program with professors Elson Longo and José Arana Varela. That was when I learned what science was and that increased my taste for the academic area. In 1984, I had the first undergraduate scholarship from FAPESP under the guidance of Professor Varela (who was a visiting professor in the Materials Engineering department (DEMa) at UFSCar). In 1988 I graduated, joined the DEMa-UFSCar master’s degree program and went to work as a development engineer at 3M do Brasil, in Sumaré, SP. My director at 3M was the engineer Aloysio Pizarro and he released me for the master’s degree (which I defended in 1990 under the guidance of Professor Elson) and for the doctorate (in 1990). In 1992, I realized it would be impossible to reconcile the research area and my activities at 3M, so I left 3M to focus entirely on my academic research, returning to São Carlos. I finished my doctorate in 1993 under the supervision of Professor José A. Varela. In January 1994, I became an adjunct professor in the Chemistry department at UFSCar and joined LIEC (Interdisciplinary Laboratory of Electrochemistry and Ceramics), founded by Elson, Varela and Bulhões (Professor Luís Otávio S. Bulhões). I went back to the place that had introduced me to science.

Those moments influenced me…

B-MRS newsletter: In your assessment, what are your main contributions to the Materials area?

Edson Roberto Leite: Ever since undergraduate research, I have been working mainly with inorganic materials, more specifically with ceramic materials. So, I will report the contributions I believe are most important, according to my point of view (in fact these may be the contributions I most enjoyed working with).

Since 1994 I have been working with chemical and physical-chemical materials and have been involved in several areas, among them: chemical synthesis of ceramic oxides, synthesis of nanoparticles with controlled size and morphology, growth of nanocrystals, electrical properties of ceramic oxides, materials for application in alternative energy devices and transmission electron microscopy (TEM). During this period, always developing works in collaboration with professors Elson Longo and José A. Varela, at LIEC of DQ-UFSCar. Among these different areas I will highlight my contributions to the growth of nanocrystals and the work on alternative energy.

In 1998, that is, 4 years after I was hired, I went on a sabbatical in the USA, in the group of Professor Martin P. Harmer, at Lehigh University (Betlehem, PA). In my sabbatical, I worked on converting polycrystalline ceramics into monocrystalline ceramics, using controlled grain growth. It was a wonderful year and my recollection of that period is vivid in my memory. I still remember the smell of the laboratory and the friendships I cultivated. From a professional point of view, the work drew my attention to the process of solid-state crystal growth. My contribution to the project was to characterize the growth process using advanced transmission electron microscopy techniques. At that time I had the opportunity to operate the VG-603 analytical transmission electron microscope. There were few microscopes like this being produced, and I still remember the words of the coordinator of the Lehigh microscopy laboratory, Dr. Dave Ackland saying that “few researchers in the world have had the honor of operating this equipment.” Returning to Brazil in 1999, I dedicated a lot of my time to microscopy and, with the help of the newly created Electronic Microscopy Laboratory of LNLS (created in 1997 by Dr. Daniel Ugarte), I began studying the process of growing nanocrystals in colloidal solution. I quickly identified, for SnO2 nanocrystals, a growth mechanism recently described in the literature known as “Oriented Attachment” (OA). The first article we published about this nanocrystal growth mechanism was in 2003. During this period I created a group of high-level master and doctoral students (today these students are researchers and professors), which truly allowed exploring this growth mechanism. In fact, we published, almost simultaneously with American groups, the first kinetic model to describe this growth process, and shortly afterwards we published two important articles, one related to the growth of anisotropic nanocrystals and the other correlating the OA process with a polymerization process. Both articles are considered pioneers in the area. International recognition in the area came with the invitation to publish two review articles (one at Nanoscale and the other at CrysEngComm), one of them in collaboration with leading international experts in the field of nanocrystal growth kinetics by OA.

I started working in alternative energy in 2004, when I helped organize a symposium on the theme at the MRS Spring Meeting in San Francisco. After that, we invested in this area and, with a new group of brilliant students, we achieved fantastic results, between 2007 and 2016, regarding the development of hematite photo anodes to promote water photo-electrolysis aimed at hydrogen production. We developed an electrode manufacturing process based on colloidal nanocrystal deposition. This enabled the highest impact publications of my career, in journals such as JACS and Energy Environ. Sci. In the same period we developed a method for synthesizing MoS2 (2D material), combining non-hydrolytic sol-gel method and microwave reaction. This again resulted in excellent materials for electrocatalysis and for supercapacitors. This research also enabled publications in high-impact journals, such as Chem. Comm and Advanced Energy Materials. Without a doubt, this team of students placed us in the state-of-the-art to develop materials for alternative energy.

I would like to highlight just one more important contribution, which was in the study of the combustion process in glass-melting furnaces, carried out with funding from White Martins/Praxair. In this work, carried out with Professor Carlos Paskocimas (currently at UFRN) and Professors Elson and Varela, we characterized the corrosion rate of the furnaces and proposed technological solutions to inhibit this corrosion. This work was a success at the time and we were invited to present the results at Corning Glass and Praxair in the United States.

B-MRS newsletter: You were celebrated in the first edition of the B-MRS José Arana Varela award, which honors this prominent Brazilian scientist (who died in 2016), former president of B-MRS. Professor Varela was your doctoral advisor and co-author of many published articles. Could you share with us some memories about Professor Varela and comment on the scientific partnership both of you developed over time? Feel free to leave any more personal comments.

Edson Roberto Leite: As I mentioned above, I was introduced to Professors Varela and Elson during my undergraduate years, and Professor Varela was my undergraduate and PhD advisor. In fact, I was Varela’s first doctoral student, in 1993. Being the first to win this award is an honor, which made me very happy. Besides being my advisor, Professor Varela was a tutor and almost a father, teaching me and introducing me to the national and international scientific community. It was with him that I made my first trip abroad, in 1993, where he introduced me to the great names of international Ceramics at the American Congress of The American Ceramic Society. It was at this opportunity that I met Professor Gary Messing and Professor Harmer. I remember him introducing me to the famous Professor W.D. Kingery, the father of modern Ceramics. It was Varela who encouraged me to be a member of World Academy of Ceramics. There were several trips, opening new work fronts and new research areas. As a tutor and advisor he knew how to get my attention and point out my mistakes. I remember, more recently, at an MRS Fall meeting in Boston (USA), a long discussion that we had where he, without hesitation, “pulled my ear” and helped me handle future problems I would face as a group leader in the Materials Chemistry area. I know he saw me as a rebellious student, but I’m sure he was proud of the training he gave me. His premature death took me by surprise and I miss him very much. I miss our discussions, our conversations and especially his advice and guidance.

B-MRS newsletter: Please leave a message for our younger readers who are starting a scientific career or are evaluating this possibility.

Edson Roberto Leite: I am not good with words, my students and former students know that I am very direct. I never worried about planning my career, everything was happening as I followed my instincts. What I am today is largely due to my students and the support of two scientific parents, professors Elson and Varela. My job is not a job, it is a hobby. So my message is: To achieve success in a scientific career you must really like what you do.

Featured paper: Antimicrobial dental implants.

Bacterial biofilms are formed by communities embedded in a self-produced polymeric matrix forming a three-dimensional structure. Biofilms grow attached to the most diverse surfaces, natural or artificial, and can include a variety of bacteria and fungi. When found on our teeth, these microbial communities can cause well-known health damage, such as dental caries. Even inside the mouth, where biofilms tend to form, dental implants can also be harmed by the action of biofilms. In fact, the main cause of failure in dental implants is related to infections in the tissues surrounding the implant, due to bacterial accumulation on the titanium screws implanted by a surgeon dentist in the jaw bone or maxilla to support the dental prosthesis.

In light of this problem, a team of researchers from areas related to dentistry and materials developed a coating capable of reducing the adhesion of bacteria and fungi to the titanium surface, thus attacking the formation of biofilms in its initial stage. In the new coating, the bacterial adhesion was eight times less than in uncoated titanium. In addition, the coating changed the composition of the microbial population in the biofilms that appeared on the surface. Thus, the presence of bacteria directly responsible for generating infections around the implants was seven times less in the coating than in the uncoated titanium. “Our coating not only reduced the adhesion of microorganisms, but also modified its composition to a less aggressive host profile,” summarizes professor Valentim Adelino Ricardo Barão (UNICAMP), corresponding author of the paper related to the study, recently published in ACS Applied Materials and Interfaces. Finally, in addition to generating antibiofilm properties on titanium, the coating maintained this material’s biocompatibility, allowing the growth of human cells on its surface, and increased its resistance to corrosion.

According to the authors of the work, this new coating may be a promising strategy to control the formation of biofilms in titanium implants and thus reduce the development of microbial infections. “Countless coatings have been developed in this area,” contextualizes Professor Barão. “However, the ones available on the market aim, mainly, to improve biomechanical properties and biocompatibility, but not effective in reducing the accumulation of microorganisms.” According to the authors of the article, in order to apply coated titanium to patients and make it available on the market, it would be necessary to test its insertion as a dental implant in animal models and, finally, to conduct a controlled clinical trial that contemplates the insertion of the material in humans.

From developing the material to in vitro and in situ studies

Nociti, Magda Feres, Elidiane Cipriano Rangel, and Valentim Adelino Ricardo Barao.

The research was carried out within the doctorate of João Gabriel Silva Souza, with guidance from Professor Barão and funding from Brazilian agencies Fapesp and Capes. The thesis was defended in 2019 in the Graduate Program on Dental Clinic of the School of Dentistry at UNICAMP Piracicaba.

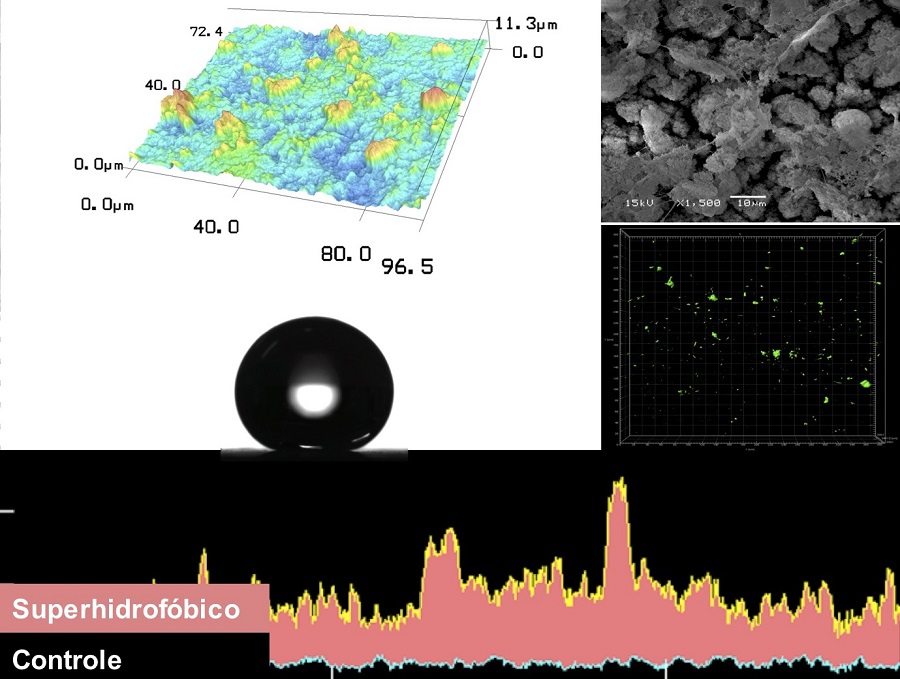

The main objective of the thesis, says Souza, was to develop a coating for titanium, a widely used material in dentistry, that has the ability to reduce microbial accumulation by using low-pressure plasma technology. Bibliographic searches have shown that a superhydrophobic surface would be a promising alternative to reduce the adhesion of bacteria to titanium and its alloys. A surface is considered to be superhydrophobic (that is, very difficult to wet) when the angle formed between it and a drop of water is greater than 150º. Superhydrophobicity, in turn, is based on high surface roughness and chemical composition.

“Based on this idea and previous studies already developed by Professor Barão’s research group, we aimed to develop a superhydrophobic coating with plasma technology, changing various parameters, such as pressure, gases, etc.” says Souza.

The coating was developed and characterized at the Laboratory of Technological Plasmas – UNESP – Sorocaba, which includes the Multi-User Laboratory for Characterization of Materials, under the guidance of Professor Elidiane Rangel. “Professor Elidiane has broad experience in the area and has been contributing extensively to our research group in the development of coatings for dental applicability,” explains Professor Barão.

While the scientific literature recorded superhydrophobic coatings manufactured mainly in two stages (one to obtain roughness and the second to achieve hydrophobicity), Professor Rangel manufactured the coating in just one step, using the technique of PECVD (plasma-enhanced chemical vapor deposition). In this technique, an atmosphere of carefully selected gases is formed inside a reactor (in this case, oxygen, argon and hexamethyldisiloxane, of the formula C6H18OSi2). This atmosphere is highly energized (in a plasma state) after applying an electrical voltage, when the gases decompose and generate species (atoms, molecules, ions) with great propensity to react chemically. These species form new compounds that are deposited in a solid state on the surface of the material to be coated (in this case, titanium).

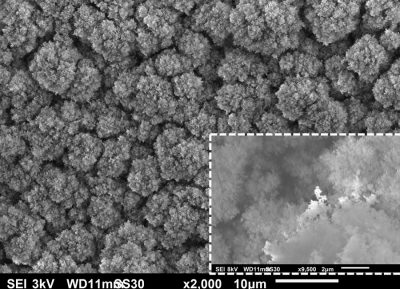

To manufacture the superhydrophobic coating using this technique, Professor Elidiane carried out a unique 60-minute process. The result was a surface based on silicon and oxygen, similar in appearance to cauliflower, with a different roughness. Making an analogy with the relief of our planet, the coating presented, on the micrometric scale, mountains of different heights and shapes, separated by valleys and canyons.

After obtaining the coating, in order to test its effectiveness as an antibiofilm, the study involved research groups from the University of Guarulhos and the University of Connecticut Health Center (USA), where the then doctoral student Souza carried out a doctoral internship.” In addition, the Brazilian National Nanotechnology Laboratory (LNNano) and the Brazilian Biosciences National Laboratory (LNBio) were used to characterize the coating and analyze the composition of adhered proteins, respectively.

The team of scientists then carried out a series of microbiological tests and analyses, both in the laboratory (in vitro) and in the mouth of volunteers (in situ), always comparing uncoated titanium and the titanium with the superhydrophobic coating. In one of the in vitro experiments, they used natural saliva as a culture medium for several microorganisms usually found in biofilms that grow on the implants. In contact with this medium, the coated titanium samples showed a very good antibiofilm performance with respect to the uncoated titanium: the adhesion of the set of microbes was eight times lower, and, in particular, the adhesion of a bacteria directly responsible for the formation of the biofilm matrix was 17 times smaller. Consequently, in a later stage of the experiment, biofilm formation in the coating was scarce and sparse.

In another interesting test, carried out in situ, four volunteers used a device on the palate during 3 days. This device was made with some untreated titanium discs and others with a superhydrophobic coating. When analyzing the composition of biofilms formed on the two surfaces, with the collaboration of professor Magda Feres of the University of Guarulhos, the researchers were once again surprised by the positive performance of the developed coating, which reduced by seven times the presence of pathogens directly associated with infections that lead to dental implant failures.

B-MRS Newsletter. Year 7, issue 3.

|

||||||||||||||||||||||

|

||||||||||||||||||||||

|

STI policies: interview with the parliamentary advisor Mariana Mazza.

We can call her a lobbyist; she doesn’t mind. Quite the opposite. Mariana Mazza, 41 years old, a lobbyist for ST&I, believes that there should be more professionals like her monitoring the actions of the Executive and Legislative Branch with an impact on ST&I and negotiating priorities with parliamentarians for the collective benefit of certain areas of research and innovation. Under names like “congressional fellow” or “advocacy dashboard,” this work has more visibility in scientific societies in other countries, such as the United States, but also exists in Brazil.

A journalist who graduated from the University of Brasília, Mariana changed, at the end of 2016, her routine as a reporter with that of parliamentary advisor to the Brazilian Society for the Advancement of Science (SBPC), a society to which B-MRS is affiliated. In turn, SBPC is one of the eight entities that coordinate ICTP.br, an initiative that brings together the efforts of Brazilian institutions relevant to CT&I in joint actions in the National Congress.

In an interview with the B-MRS Newsletter, Mariana talks about her daily activities as a parliamentary advisor in ST&I, the main achievements and the challenges for the immediate future, in a time of resources scarcity and a pandemic.

B-MRS newsletter: What is your job? What activities do you carry out in your day-to-day parliamentary assistance?

Mariana Mazza: The activities I carry out for the SBPC have a broader scope than simply talking to congressmen and senators, as anyone unfamiliar with the National Congress may think. It’s quite dynamic, actually. There are basic activities such as evaluating the agendas of the House and Senate commissions and screening everything that may have an impact on ST&I. As SBPC has hundreds of associates in multiple areas, this is a very broad job. But the most critical part is to identify and evaluate political actions that can be passed in the National Congress. For example, we have done a very thorough job of recovering the budget for ST&I and R&D. This requires that I follow the budget proposal from the beginning, calculate the variations in relation to previous budgets and suggest strategies to the SBPC board. Once the strategies are outlined, the negotiating part begins with amendments that put more money into projects, which means writing these proposals and explaining them to the advisors of each office. To give you an idea, just for the 2020 Budget, I personally went to more than 300 offices of the Congress and the Senate. And this is just a part of what we do. Basically, any action by the Executive that can be reversed in Congress requires an action by the advisors in some aspect. And there are also bills from the Legislative itself that affect the scientific community and often need repair. I mediate the representatives of the SBPC with the representatives of these projects and members of the committees that can improve the proposal. We also organized scientific dissemination exhibitions, such as the Centennial of Eclipse in Sobral last year, which was very well received by visitors to the Congress. And there is also the work to expand awareness of the SBPC itself by parliamentarians. As the SBPC is a very active entity in the political discussions important for the country, there is no lack of work for parliamentary assistance.

B-MRS newsletter: Who do you interact with? How do you choose who to interact with?

Mariana Mazza: It depends on the subject we are dealing with. Parliamentarians have their niche. So, if the subject is the environment, there is a group of parliamentarians open to dialogue in line with SBPC’s activities. If it’s innovation, it’s another group. For budget, it’s other parliamentarians. And so on. But as Brazilian science increased its presence in the National Congress, we expanded our network of parliamentarians allied to CT&I, which we look for in the most strategic matters regardless of the specific area, so to speak. This web of science-friendly parliamentarians was woven in various ways. There are historical allies, who have supported science for years, and those who have identified themselves with the agendas we have taken on, better understanding how science works and its implications in the lives of Brazilians. It would be difficult to list them because it would leave out many of them. After the 2018 elections, we lost many congressmen and senators aligned with the scientific agenda. But luckily we have been able to open a new space in Congress, getting support from many leaders using the strategy of defending specific agendas. In the withdrawal of the FNDCT from the PEC Funds, for example, we were able to articulate with the leaders and other entities in the sector a supraparty support for the preservation of science resources. It is very gratifying when we can demonstrate that science is not an ideological agenda, of the left or right. It is an agenda for the benefit of all. Politicians are starting to see this.

B-MRS newsletter: You have a degree in Social Communication – Journalism and experience as a TV journalist. What skills do you use in this parliamentary advisory work?

Mariana Mazza: Yes, I am a journalist by training. Before joining SBPC, I worked at Grupo Bandeirantes as an editor and columnist. In my career as a reporter, I specialized in the area of infrastructure, which actually led me to Band media group, as a columnist for Telecommunications. It is public knowledge that the infrastructure sector is very active in the political lobby, although much of the social perception is on the negative side. Major service providers – such as telcos, energy distributors, fuel producers, airlines, contractors and media groups, which make up an infra reporter’s agenda, are extremely active in lobbyism. Following the operation of these sectors in the National Congress for more than a decade has taught me very much about how sectoral negotiations work in parliament. For instance, what kind of arguments work with politicians, how to approach them and how to present a cross-sectoral agenda.

B-MRS newsletter: Your work is not common in Brazil in the scientific environment, right? Do you get inspired or learn from professionals in other fields or from other countries?

Mariana Mazza: It’s not that uncommon, actually. Entities such as Fiocruz and Embrapa, which belong to the National System of Science, Technology and Innovation (SNCTI), are very professional in their work in the National Congress, with teams dedicated only to negotiating with parliamentarians and analyzing actions in the legislature. And there are important civil entities that do very diligent work in congress, defending and guiding the benches in specific sectors. The Socio-Environmental Institute (ISA), for example, has a very important role in the environmental agenda. I think what happens is that this is an “in the shadows” job, most of the time. When it works, it looks like it hasn’t even been done. The lobbyism is still very frowned upon in Brazil, because we are usually only aware of it when it is used for the benefit of some sector rather than for the collective benefit. This results in lobbyists in Brazil disguising their activities with other names, “parliamentary advisers,” “directors of institutional relations,” and so on. This helps to hide the bad lobby service, so to speak, but it also ends up taking away the visibility of the republican work of negotiating priorities with parliament. I believe that all sectors have the right to negotiate with representatives elected by society. It is like the work of a lawyer. Guilty and innocent people have a right to defend themselves. I am privileged to advocate in defense of a sector that I sincerely believe is beneficial for the development of any nation. But when working with politics, one must keep in mind that there is always a perspective that is opposite to ours. We have to face the negotiations without sentimentality. We need to find a common ground. Ironically, I end up being more inspired by business lobbyists, considered “bad” by society, simply because they are efficient in their performance. As a reporter I met many lobbyists, and became close over the years, and I learned quite a bit from them.

B-MRS newsletter: What is the Science and Technology Initiative in Congress (ICTP.br)? Does your work fall under this initiative?

Mariana Mazza: ICTP.br is an initiative to join the efforts of national entities relevant to ST&I in joint actions in the National Congress. It derived from an idea by SBPC’s chair Professor Ildeu de Castro Moreira to create an observatory for the Legislature. The idea was developed in partnership with former-minister Celso Pansera, who held a mandate as a federal congressman, when we started to prepare the project in 2018. Today, Pansera takes care of the executive secretary of ICTP.br, articulating the major guidelines that impact ST&I with the party leaders in an agenda of priorities that we jointly defined among the eight institutions that make up the coordination of ICTP.br: SBPC, ABC, Andifes, Consecti, Confap, Forum of Secretaries of ST&I, Conif and Confies. As a parliamentary advisor to SBPC, I have worked together with the ICTP.br agendas, but not all actions overlap. There are several guidelines that I have to address and because they are specific they are not on the Initiative’s agenda. On the other hand, the establishment of this coordinated operation eased performance in the heaviest national guidelines, which before ICTP.br they would fall on the advisors in an unarticulated way. Today, such actions on these high-impact agendas are much more organized, with former-minister Pansera at the head of the broader political articulations, with advisers like me taking on the ground work of building arguments and assisting the offices to implement the agreements signed. It is still work in the makings, but we have already had great results in improving the interaction between entities and winning gains in Congress.

B-MRS newsletter: What were the achievements achieved so far with the help of your work?

Mariana Mazza: There are many. Especially because most, as I said before, don’t even get visibility because they end up as a task to put out small fires. However, in terms of general repercussions, we have been very successful in the budget agenda, although today this action is more about containing losses than increasing resources for ST&I. I can safely say that the financial situation of the sector would be much more precarious if it were not for the work of the advisors and directors of the entities in containing the bleeding. Also regarding the big agendas, the action in Congress was what guaranteed the missing funds for the payment of CNPq scholarships in 2019. That maintained the existence of Finep, by blocking the initiative to transfer the executive secretary of the FNDCT to the MCTIC. That saved the FNDCT from possible extinction by removing it from the PEC of the Funds. That prevented the contingency of science resources at MCTIC in 2020. That also protected the entire budget of Embrapa, Fiocruz, IBGE and Ipea this year. Not to mention the countless denunciations that SBPC makes in its public notes and open letters that have enormous repercussions in Congress, containing the advance of harmful measures for Brazilian science. The testimonial of this type of work, as you can see from the examples I cited, is that we are currently being compelled to act more in containment than in proposition. It is important to remember, for example, that it was the performance of science in Congress that embodied the Legal Framework of CT&I, an operation that lasted many years of dedicated negotiation by advisers at that time.

B-MRS newsletter: What have been the main challenges or difficulties?

Mariana Mazza: The main difficulty is that we have many entities in the scientific area, but few with political activities in Brasília. As a result, many opportunities for specific actions are lost, which an advisor like me, from a national entity, cannot follow with the necessary dedication. It would be especially positive if associations and civil entities that do not operate in Congress started to insert this on their agendas. But it should be understood that parliament works with concrete guidelines. Acting in Congress in the pursuit of “defense of ST&I” quite simply – this is in fact true for any sector – becomes very frustrating very quickly. Because parliamentarians deal with dozens of topics at the same time and are therefore pragmatic. You need to know what you want before stepping into the National Congress. The challenge is that we are in a political and economic moment of deep retraction in public investments. And the ST&I sector is an expensive sector in the view of many parliamentarians, who are unaware of the vast Brazilian research network and its fruits throughout history. Although we have made significant progress in recent years, science is still seen by many in Congress as having low political repercussions in the electorate of these parliamentarians. And then we lose support for guidelines considered by them to be of greater social appeal. Therefore, the greater the presence of scientific entities in parliament, the greater the space for parliamentarians to discover the benefits of Brazilian science for their political agendas. We have seen this path opening up. Our collective goal is to naturalize the stimulus to science in the National Congress. The latest victories achieved this year show that we are on the right path, but there is still much to do, such as moving from a just reactive agenda to the continuation of propositional guidelines. But, as Bismarck’s famous phrase: “Politics is the art of the possible.” At this time, what is possible is to prevent further setbacks.

B-MRS newsletter: In this new and difficult scenario, marked by the advance of the Covid-19 pandemic in Brazil, unpaid funds, budget cuts and various uncertainties and instabilities, what are your action plans for the coming times?

Mariana Mazza: We are very concerned with the little attention given to science by the government in plans to fight the coronavirus outbreak. To repair the low budget for research in this area, we are already negotiating increases in resources with parliamentarians using the budget instruments sent by the Executive Branch. We are also already preparing to work on raising ST&I and R&D funds in the emergency plan announced by the federal government to mitigate the economic effects of the pandemic. We understand that investing in science, as other countries have done, is also vital for the national economy and we are in daily dialogue with the closest offices, drawing up action strategies. One of our great battles, inside and outside the National Congress, has been the end of the capture of FNDCT resources by the Contingency Reserve. This is a tax mechanism that is essentially illegally withdrawing money from science to meet government tax targets. We also want this reserve to be released now, in its entirety, to fight the coronavirus and foster science in general, recognizing its role in the economic recovery of the recession that will certainly hit Brazil after overcoming the pandemic. At the present time, all energy is focused on ensuring the presence of science in emergency plans and blocking any action that would harm science in this period of crisis.

Featured paper: A molecular machine to fight cancer.

[A reversible, switchable pH-driven quaternary ammonium pillar[5]arene nanogate for mesoporous silica nanoparticles. Santos, ECS ; dos Santos, TC; Fernandes, TS; Jorge, FL; Nascimento, V; Madriaga, VGC ; Cordeiro, PS; Checca, NR; Da Costa, NM; Pinto, LFR; Celia Ronconi. J. Mater. Chem. B, 2020,8, 703-714. https://doi.org/10.1039/

A molecular machine to fight cancer

In 2016, the smallest man-made machines ever created, called molecular or nanomachines, gained visibility with the Nobel Prize in Chemistry. These nanometer-sized machines, whose components are molecules that perform controlled movements, could help humanity accomplish complex tasks at the molecular scale.

In the health area, one such task is to effectively fight cancer cells without damaging healthy tissues. It is known that nowadays one of the main problems of the most used therapies concerns the side effects on healthy tissues – a problem that has led many scientists to develop drug delivery systems that can take drugs directly to cancer cells without leaking.

At the Brazilian Federal Fluminense University (UFF), over the last ten years Professor Célia Machado Ronconi and her scientific team have been working on nanomachines for cancer treatment. In her postdoctoral research, carried out between 2003 and 2005, the scientist learned about molecular machines at the University of California, Los Angeles (UCLA), at one of the most qualified laboratories in the world working on this subject – the research group of Sir James Fraser Stoddart, who years later would be awarded the Nobel Prize mentioned at the beginning of this article, alongside with Jean-Pierre Sauvage and Bernard L. Feringa.

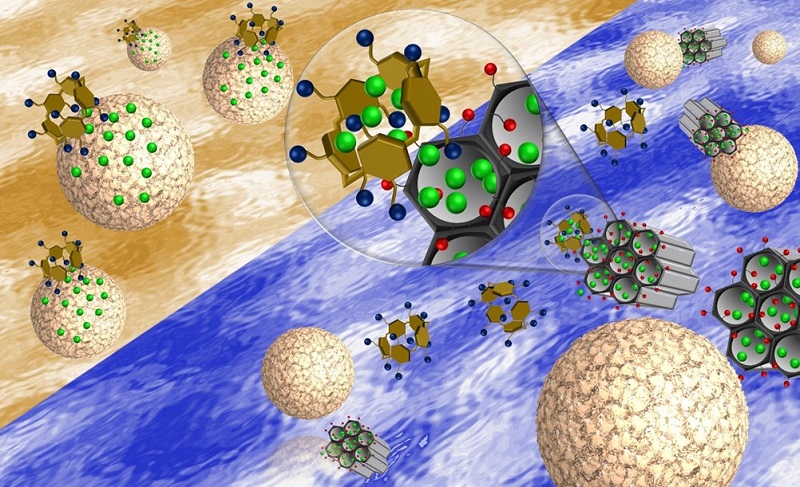

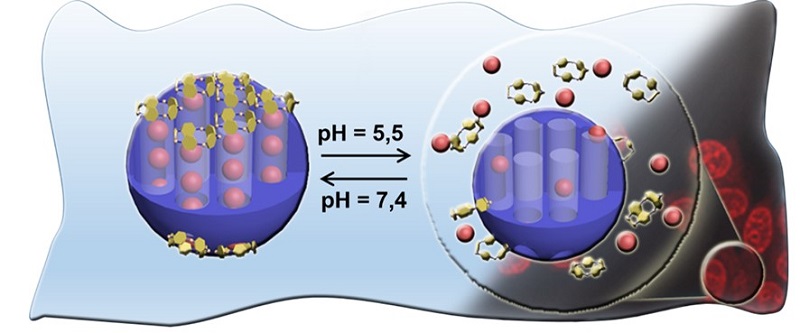

In a recently published paper in Journal of Materials Chemistry B, Professor Célia Ronconi, her team and collaborators, all from Brazilian institutions, presented a new nanomachine composed of a drug reservoir and a cap. The machine has an opening/closing lid mechanism that responds to changes in the acidity of the medium in which it is located. When the pH of the medium is similar to that of the blood of a healthy human being (physiological medium), the cap remains closed, preventing the drug from being released. When the pH is more acidic, a characteristic seen around cancer cells, the lid opens and the drug is released. In laboratory in vitro tests, the nanomachine loaded with a well-known chemotherapeutic drug proved to be more effective than the pure drug in eliminating breast cancer cells, destroying 92% of them in 48 hours.

With these characteristics, the nanomachine developed at UFF shows application potential in the delivery of chemotherapeutic drugs to cancer cells. “The results of this work were extremely promising,” says Professor Ronconi. “However, there is still much to be studied. The next steps of the work will be to test the nanomachine loaded with the drug in other breast cancer cell lines, as only one line (MCF-7) was tested. We will also test the toxicity of the device without the drug in healthy cells and, if the results are positive, in vivo studies will be carried out, using mices genetically altered to have a deficient immune system, ” adds Professor Ronconi.

Assembly and operation of the nanomachine

To achieve the reservoir function, the UFF group synthesized spherical mesoporous silica nanoparticles of about 85 nm in diameter. In addition to being biocompatible, this material has a unique internal honeycomb-like structure, with a set of nanochannels of up to 4 nm in diameter, in which the drug molecules can be stored. The nanoparticles were covered with carboxyl groups (- COOH) that improved the interaction of the reservoir with its cap. For the cap, the researchers chose pilararene, an artificial molecule made up of five aromatic rings, whose first synthesis dates back to 2008 in the scientific literature.

In the assembly and operation of the nanomachine, the electrostatic interactions of attraction controlled by the medium pH were the great allies of the scientific team at UFF. In fact, as confirmed by the researchers in their experiments, in a solution with a pH of 7.4, which represents the acidity of healthy blood, the carboxyl groups (-COOH) that cover the reservoir lose a proton forming carboxylate groups (-COO- ), negatively charged, which interact electrostatically with the positively charged cap. Thus, the electrostatic attraction brings the two parts of the nanomachine together until it prevents the drug from being released. By lowering the pH, that is, by making the solution more acidic, the carboxylate groups (-COO-) gain protons, neutralizing their charge. As a result, the electrostatic attraction between the cap and the reservoir breaks apart, the cap opens and the drug is released.

In the experiments carried out, the UFF group was able to partially release the chemotherapeutic drug (34%) at a pH of 5.5 (probably similar to that surrounding the cancer cells) and almost totally (91%) in a 2.0 acidity medium. All experiments were carried out at a temperature of 37 °C, similar to that of the human body.

History of work

Since 2009, when she became a professor at UFF and set up the Laboratory of Supramolecular Chemistry and Nanotechnology, Professor Célia Ronconi has been working in the different development phases of diverse nanomachines and drug transport and release systems, using chemical, magnetic and luminous stimulants. During Evelyn da Silva Santos’ doctorate, under the guidance of Ronconi, a nanomachine prototype was developed using material available on the market. However, new studies carried out after the defense of her doctorate work, in 2018, showed that the nanoparticles used as reservoirs formed clusters in the physiological environment (the solution that emulates blood in experiments). Thus, Professor Ronconi involved postdoctoral fellow Thiago Custódio dos Santos and doctoral student Tamires Soares Fernandes in the development of new material. “They continued the project and synthesized a material with excellent dispersion in the physiological environment, and the device was redone, as well as the drug release studies,” says professor Ronconi. The biological tests of the nanomachine were performed at INCA’s molecular carcinogenesis group, by researchers Luis Felipe Ribeiro Pinto and Nathália Meireles da Costa, and the technician Fernanda Jorge. The study also included the participation of the Brazilian Center for Research in Physics (CBPF) in the characterization of materials by microscopy techniques, carried out at the Multi-User Laboratory for Nanoscience and Nanotechnology (LABNANO). The research received funding from the Brazilian agencies CNPq, CAPES and FAPERJ.

(Português) SBPMat subscreve manifestação da SBPC sobre o pronunciamento do Presidente da República a respeito da pandemia de Covid-19.

B-MRS & ICEM: update on the Corona virus.

Owing to the uncertainties related to the COVID-19, and in order to reduce the risk of hampering the health of our community, the Organizing Committee, the Executive Board of the B-MRS and the IUMRS decided to postpone the 2020 B-MRS and the IUMRS/ICEM meetings.

Owing to the uncertainties related to the COVID-19, and in order to reduce the risk of hampering the health of our community, the Organizing Committee, the Executive Board of the B-MRS and the IUMRS decided to postpone the 2020 B-MRS and the IUMRS/ICEM meetings.

The conferences are now scheduled to happen from August 29th until September 2nd, 2021, in the city of Iguassu Falls, at the Rafain Convention Center.

All participants will be asked to resubmit their abstracts following a new schedule to be released.