[Paper: O artigo científico com participação de membros da comunidade brasileira de pesquisa em Materiais em destaque neste mês é: Predicting glass transition temperatures using neural networks. Daniel R.Cassar, André C.P.L.F. de Carvalho, Edgar D. Zanotto. Acta Materialia. Volume 159, 15 October 2018, Pages 249-256. https://doi.org/10.1016/j.

Artificial Intelligence to develop new glasses

Glasses, materials used in a wide variety of products, from a bottle of wine to a dental implant, can make new contributions to the quality of life of humans and animals, and to the preservation of the planet. In fact, so far, about 400,000 (4 x 105) glass formulas have been produced and published, while 1052 new glasses can still be developed using possible combinations of 80 friendly elements from the periodic table.

In order to deal with this myriad of possibilities, it is vital to count on the help of sophisticated computational tools that indicate the most promising chemical formulas in terms of their physicochemical properties. Recent tools use artificial intelligence, mainly algorithms of the so-called “machine learning.” After adequate training with known data, these tools can perform the initial screening that allows deciding in which formulas it is worth investing resources (time, money, efforts) to develop them in the laboratory.

This was the direction chosen by a Brazilian team that brought together researchers from the Materials and Computing areas, and created a machine learning computer tool (an artificial neural network) that proved capable of effectively predicting the glass transition temperature (Tg), which is an important property of glass that depends on its composition [See box].

This was the direction chosen by a Brazilian team that brought together researchers from the Materials and Computing areas, and created a machine learning computer tool (an artificial neural network) that proved capable of effectively predicting the glass transition temperature (Tg), which is an important property of glass that depends on its composition [See box].

The work was reported in a scientific paper recently published in the journal Acta Materialia (impact factor 6,036, and 22% acceptance rate).

“The main contribution of the article was to demonstrate the possibility of predicting an important property of oxide glasses (in this case Tg) using an artificial neural network,” says Edgar Dutra Zanotto, professor at the Brazilian Federal University of São Carlos (UFSCar) and one of the paper’s three authors. “The only information needed to make such a prediction is the chemical composition of the material,” he adds.

Artificial neural networks are widely used, for example, for facial recognition in large facial image databases, but their application in Materials research is still scarce and incipient. In the area of vitreous materials, for example, the article by Zanotto and coauthors is the third paper that reports the use of this computational tool.

Artificial neural networks are distributed computing systems made up of data units (equivalent to simplified neurons) interconnected through connections that are equivalent to synapses. They learn through learning algorithms. Working together, the “neurons” can process large volumes of data and make predictions, but for this the network needs to be trained based on concrete examples.

Zanotto’s approach to artificial neural networks began about two years ago when he thought of looking for artificial intelligence tools to facilitate the search for new glass formulas. The idea attracted great interest from Daniel Roberto Cassar, postdoctoral fellow at the Laboratory of Glassy Materials (LaMaV) of the Department of Materials Engineering (DEMa) of UFSCar, coordinated by Zanotto. Cassar then participated in courses and lectures on neural networks and began to venture into the development of neural networks applied to the study of glasses.

About a year ago, these materials scientists felt the need to rely on an artificial intelligence specialist and began collaboration with Professor André Carlos Ponce de Leon Ferreira de Carvalho, a professor at the Institute of Mathematical and Computer Sciences (ICMC) of the University of São Paulo (USP) at São Carlos. Thus, the research ended up involving a series of postdoctoral research fellows from both groups, all located in the city of São Carlos.

The team designed and implemented an artificial neural network, which was trained so that it could correlate Tg and chemical composition. The training was performed with Tg data and the composition of about 45,000 glasses based on the combination of 45 chemical elements. Each of the formulas used in the training contained at least 3 elements and a maximum of 21 elements. All the data were extracted from a glassy material database that collects experimental data extracted from the scientific literature.

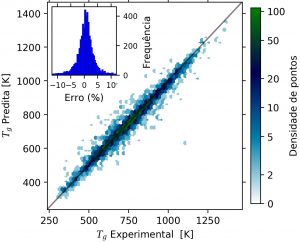

After training the network, the scientists tested its ability to predict Tg. This was done by informing the network the chemical composition of another 5,515 glasses, also present in the database, but that had not been used in the training. When comparing the values predicted by the neural network with the values obtained by means of experimental methods, present in the database, the scientific team was positively surprised. The artificial neural network performed very well in the responses, erring at most 6% up or down in temperature values in 90% of the tests – a level of uncertainty very similar to that exhibited by the experimental studies. In addition, the degree of precision of the results has been shown to be independent of the amount of chemical elements in the glass composition, which is important when thinking about probing materials with extensive chemical formulas.

The neural network of São Carlos is poised to help scientists and materials engineers worldwide to quickly estimate the Tg of any composition glass, making research and development of new glass much faster, easier and more economical. In addition, the study conducted by Cassar, Carvalho and Zanotto shows a path that can be followed to develop new neural networks applied to Materials Science and Engineering. “This result opens a wide path for similar studies aimed at predicting almost all the physico-chemical properties of glass based on their composition!” says Zanotto.

In fact, in the groups of professors Zanotto and Carvalho, a little more than a year after the beginning of the collaboration, a series of works on the subject is now underway. These studies shall generate: new algorithms to further improve neural networks, new networks trained to predict other properties (refractive index, modulus of elasticity, liquidus temperature, etc.), more knowledge about the performance of machine learning algorithms, new scientific articles and software tools to be used by the community.

The work that originated the article published in Acta Materialia was funded by the São Paulo State Research Foundation FAPESP, through the Research, Innovation and Dissemination Centers CERTEV (Vitreous Materials) and CeMEAI (Applied Mathematical Sciences). The research also received funding from the Nippon Sheet Glass Overseas Grant (Japan).