Every year, at the end of the meeting of the Brazilian Materials Research Society, the next year’s event is announced: its date, chairs and, most importantly, the city where it will be held. However, with Foz do Iguaçu, one of the most beautiful destinations in the world, things happened differently. The announcement was made in September 2019, but the event only took place three years later. The blame for the delay was, of course, the pandemic. In 2020, the meeting was postponed. In 2021, it was carried out in an online format, always under the coordination of Professor Gustavo Dalpian (UFABC), who skillfully dealt with the challenges of a difficult period. Finally, in September 2021, at the end of the online meeting, Professors Lucimara Stolz Roman (UFPR) and Marcela Mohallem Oliveira (UTFPR), were presented as the chairladies of the XX B-MRS Meeting, and announced what many expected: the event would be held in Foz do Iguaçu, the following year.

This is how, after three years without face-to-face meetings, around 1,100 people from the five continents of the planet and the five regions of Brazil gathered in Foz do Iguaçu from September 25 to 29, 2022. “The twentieth meeting of B-MRS was very important for the materials community to meet in person again after the Covid-19 pandemic”, said Professor Lucimara. “The joy of the people, the students, especially those who were attending a face-to-face conference for the first time, was contagious”, expressed the chairlady.

Along that week, human warmth made up for the cold weather which was unusual for the season. And the event’s venue, the Rafain hotel’s convention center, perfectly accommodated the participants, allowing them to spend the whole day there without being exposed to the rain, and providing interactions, not only in the presentation rooms, but also in the large space that became an exclusive restaurant for the attendees, and in the wide corridor with tables and chairs that were always occupied by groups of researchers and students. Adjacent to the hotel’s garden, the corridor welcomed participants every morning to the sound of the song of several Atlantic Forest birds. Another environment of many exchanges was the space that comfortably contained the secretary, the 22 exhibitors’ stands, the coffee break tables and the posters. There, participants could circulate freely, satisfying their curiosity about the products and services for materials research that were exhibited or demonstrated in the stands, or exchanging scientific ideas with the posters´presenters.

“This exciting return to a face-to-face meeting with many participants was made possible not only by the fact that science won the battle of Covid, but also by the strength and resilience of our interdisciplinary community, which came to the event despite all the difficulties we face at the moment in the country”, said professor Mônica Cotta (Unicamp), B-MRS President.

And it is worth mentioning: the abundant face-to-face exchanges coexisted with virtual exchanges throughout the event. Hundreds of stories and posts from participants bubbled up on social media, extending the reach of face-to-face moments.

Emotions in the opening session

On Sunday, September 25, around 7:30 pm, around 900 people occupied the Amazônia room at the Rafain convention center. Number above expectations: several had to stand in the back of the room. The desire to participate was strong! “Looking at that event room with hundreds of people in the audience was so exciting for me, I had a unique feeling of happiness to have participated in this organization after the pandemic and to see that we were able to structure ourselves, to return to our normal”, said chairlady Lucimara.

We were in the twentieth edition of the B-MRS annual event, but it was the first time that gender parity was seen at the opening table. There were three women at the table, and in the leadership: the two chairs of the event and the B-MRS President. Besides them, Professors Rodrigo Martins (NOVA, Portugal) as president of the International Union of Materials Research Societies (IUMRS), Guillermo Solórzano (PUC-Rio) as leader of the creation of B-MRS and first President of the society, and Roberto Faria (IFSC-USP), honored with the Joaquim da Costa Ribeiro Memorial Lecture – a B-MRS distinction for researchers of the community with a long trajectory and solid contributions.

In her speech, the B-MRS President told a story that happened in the 1990s that reinforces the importance of representativeness in workplaces. Chairlady Lucimara, who was a student at the time, was at Unicamp participating in an event when she visited a laboratory coordinated by Mônica, who was starting her career as a research professor at the Institute of Physics Gleb Wataghin (IFGW). The young Lucimara was surprised to see, for the first time, a woman coordinating a lab of experimental physics, which made her think that a career in this area would be possible. Today, Lucimara coordinates a productive research group on physics of materials at UFPR, and Mônica is the director of the IFGW. At the end of her speech, the president took the opportunity to present and launch the new visual identity of B-MRS, developed to celebrate the society’s 21 years, conveying the strength, excellence, enthusiasm, cohesion and diversity of the Brazilian materials research community.

In her presentation, Professor Lucimara called attention to the names of the rooms where the symposia would take place in the coming days: Rio de Janeiro, Foz do Iguaçu, Recife, Florianópolis, Natal, Guarujá, Ouro Preto, Gramado, Campos do Jordão, João Pessoa, Campinas, and Balneário Camboriú. For those who had not yet discovered the criteria behind the choice, she revealed that these were the names of the cities in which B-MRS meetings have already been held over the 20 editions. And “Amazônia”, the name of room for the plenary sessions? “The name of this room refers to the concern with sustainability that our scientific community has and needs to have”, she explained.

Then, in an presentation illustrated with many documents, Professor Solórzano told the story of the origins of B-MRS, emphasizing that the society was born with a proposal of interdisciplinarity and integration with the international scientific community. “In the first B-MRS Meeting we had 400 participants from 18 countries”, highlighted the founding partner.

Watch Guillermo Solórzano’s presentation:

Finally, Professor Gregório Faria (IFSC-USP) took the stage to introduce none other than his father, Professor Roberto Mendonça Faria, the main honoree of the night, who was president of B-MRS from 2012 to 2015. “It’s not easy for me talk about the Professor, the father, the grandfather”, said Gregório, moved, in the year that Professor Roberto turned 70 years old. “Something that makes me very proud is the way his peers treat him, which has to do with the fact that he always thinks about the community first,” said the son.

In his presentation, following the characteristic approach of the memorial lectures, of recovering the memory of the Brazilian materials research, the honoree spoke about groups that participated in the beginnings of polymers research in Brazil: the Bernhard Gross Polymer Group (IFSC-USP), which Faria has been a part of since the 1970s when it was called Electrets Group, and two large national networks in the area of polymeric and organic materials, of which he was coordinator, the Multidisciplinary Institute of Polymeric Materials of the Millennium from 2002 and the National Institute of Organic Electronics since 2009.

During the lecture, Faria enthusiastically explained the main results achieved by these groups, which reflected the evolution of the area, from the study of insulating polymers and their application in the electret microphone, to research on electronic polymers and their use in electronic devices such as OLEDs and solar cells.

Watch Roberto Faria’s presentation:

From 8:00 pm on, the participants fraternized in a great opening cocktail, served in the convention center, where there was no lack of hugs, laughter, conversation… in short, the joy of a face-to-face reunion!

High academic and social impact science in plenary sessions

The technical program began, once again, before the opening, on Sunday afternoon, with around 120 participants in the traditional “Young Researchers’ School”, a tutorial for young researchers on how to do high-impact science, from the initial idea (always audacious) to the difusion of the article on social networks, without forgetting the writing of the paper and the back and forth of the publication process. This edition of the tutorial also featured the novelty of advices for postdocs on how to continue their scientific career. The tutorial was given by Professor Valtencir Zucolotto (IFSC-USP), who is editor of the Nanomedicine and Nanotoxicology Book Series (Springer-Nature) and the journal Frontiers in Sensors/Biosensors (Frontiers), and by Daniel Staemmler, Executive Publisher at Elsevier in the field of Materials Engineering. The tutorial is based on practical tips and examples on technical and behavioral aspects of scientific practice.

The technical program began, once again, before the opening, on Sunday afternoon, with around 120 participants in the traditional “Young Researchers’ School”, a tutorial for young researchers on how to do high-impact science, from the initial idea (always audacious) to the difusion of the article on social networks, without forgetting the writing of the paper and the back and forth of the publication process. This edition of the tutorial also featured the novelty of advices for postdocs on how to continue their scientific career. The tutorial was given by Professor Valtencir Zucolotto (IFSC-USP), who is editor of the Nanomedicine and Nanotoxicology Book Series (Springer-Nature) and the journal Frontiers in Sensors/Biosensors (Frontiers), and by Daniel Staemmler, Executive Publisher at Elsevier in the field of Materials Engineering. The tutorial is based on practical tips and examples on technical and behavioral aspects of scientific practice.

More examples of high (or very high) impact science came throughout the week in the plenary lectures of the event, given by world-renowned scientists, which led participants to imagine a more or less near future, lead by techniques, materials and devices increasingly intelligent, efficient and sustainable. Held in the Amazônia room, the plenary sessions had 400 to 600 people in the audience. “Our scientific program was, once again, strong and diverse, bringing experts from around the world to cover frontier science. It motivated us to pursue quality science in Brazil and to use the results to improve quality of life of our population”, said Mônica Cotta.

On Monday afternoon, Professor Christine Kranz showed the fantastic work of her group at the German University of Ulm (Einstein’s hometown). The group integrates different probe scanning techniques and adapts the instruments to study electrochemical processes while they are happening. The scientist, who is an associate editor of the journal Bioelectrochemistry (Elsevier), showed interesting results obtained with this instrumentation in the study of biofilms and antibacterial materials, catalysts for the production of hydrogen and new batteries.

On Monday afternoon, Professor Christine Kranz showed the fantastic work of her group at the German University of Ulm (Einstein’s hometown). The group integrates different probe scanning techniques and adapts the instruments to study electrochemical processes while they are happening. The scientist, who is an associate editor of the journal Bioelectrochemistry (Elsevier), showed interesting results obtained with this instrumentation in the study of biofilms and antibacterial materials, catalysts for the production of hydrogen and new batteries.

On Tuesday morning, Professor Daniel Ugarte (Unicamp) received the José Arana Varela Award. The distinction has been granted annually by B-MRS, since last year, to an outstanding researcher from the Brazilian materials research community, who delivers one of the plenary lectures at the B-MRS Meeting. A world-renowned expert in electron microscopy, Ugarte has distinguished himself in the study of the properties of nanosystems since the beginning of his career, when he was on the cover of the journal Nature as the sole author of an article on fullerene nanoonions. This was the starting point for a series of publications in this and other high-impact journals, such as Science, Nature Nanotechnology, Nano Letters and Physical Review Letters. “He never gives up on his ideals of research excellence and academic integrity,” said Mônica Cotta, who introduced the Ugarte plenary lecture and presented him with the award. But Professor Ugarte’s contribution to the materials community went beyond the papers. In the 1990s, he conceived and set up an open, multi-user electron microscopy laboratory within the Brazilian National Synchrotron Light Laboratory (LNLS), in Campinas. “Daniel’s crazy idea worked extremely well, providing excellent microscopists to the world and forming the basis of what is now known as the National Nanotechnology Laboratory at CNPEM”, highlighted Cotta.

On Tuesday morning, Professor Daniel Ugarte (Unicamp) received the José Arana Varela Award. The distinction has been granted annually by B-MRS, since last year, to an outstanding researcher from the Brazilian materials research community, who delivers one of the plenary lectures at the B-MRS Meeting. A world-renowned expert in electron microscopy, Ugarte has distinguished himself in the study of the properties of nanosystems since the beginning of his career, when he was on the cover of the journal Nature as the sole author of an article on fullerene nanoonions. This was the starting point for a series of publications in this and other high-impact journals, such as Science, Nature Nanotechnology, Nano Letters and Physical Review Letters. “He never gives up on his ideals of research excellence and academic integrity,” said Mônica Cotta, who introduced the Ugarte plenary lecture and presented him with the award. But Professor Ugarte’s contribution to the materials community went beyond the papers. In the 1990s, he conceived and set up an open, multi-user electron microscopy laboratory within the Brazilian National Synchrotron Light Laboratory (LNLS), in Campinas. “Daniel’s crazy idea worked extremely well, providing excellent microscopists to the world and forming the basis of what is now known as the National Nanotechnology Laboratory at CNPEM”, highlighted Cotta.

In the lecture, Ugarte spoke passionately about the historical evolution of transmission electron microscopy, which today provides, in addition to images, a lot of quantitative information, and its impact on the study of nanomaterials and nanosystems. The presentation did not lack moments of great emotion when the scientist shared his affection and admiration for people in the community, such as Ricardo Rodrigues, one of the LNLS developers, who died in 2020.

Watch Daniel Ugarte’s presentation:

“Through the awards given to professors Faria and Ugarte, the community was able to express once again its gratitude to the researchers who dedicate their lives to materials science in Brazil”, highlighted professor Lucimara. “We have to value our scientists in order to strengthen our community”, she added.

On Tuesday afternoon, the plenary showcased materials science working closely with industry in manufacturing and materials processing. The speaker was Professor Sanjay Sampath, from the State University of New York at Stony Brook (USA), who directs a National Science Foundation (NSF) thermal spray research center, with a large participation of companies. With great enthusiasm, he presented efforts to improve this technique, which can be used to deposit coatings, mainly refractory ceramics, on large surfaces of various materials, with an impact on industries such as automotive, aerospace, energy, construction and prostheses, among others. The scientist, who carries out both fundamental and applied research, showed that apparent limitations of the technique can be transformed, through scientific research, into possibilities for new applications.

On Tuesday afternoon, the plenary showcased materials science working closely with industry in manufacturing and materials processing. The speaker was Professor Sanjay Sampath, from the State University of New York at Stony Brook (USA), who directs a National Science Foundation (NSF) thermal spray research center, with a large participation of companies. With great enthusiasm, he presented efforts to improve this technique, which can be used to deposit coatings, mainly refractory ceramics, on large surfaces of various materials, with an impact on industries such as automotive, aerospace, energy, construction and prostheses, among others. The scientist, who carries out both fundamental and applied research, showed that apparent limitations of the technique can be transformed, through scientific research, into possibilities for new applications.

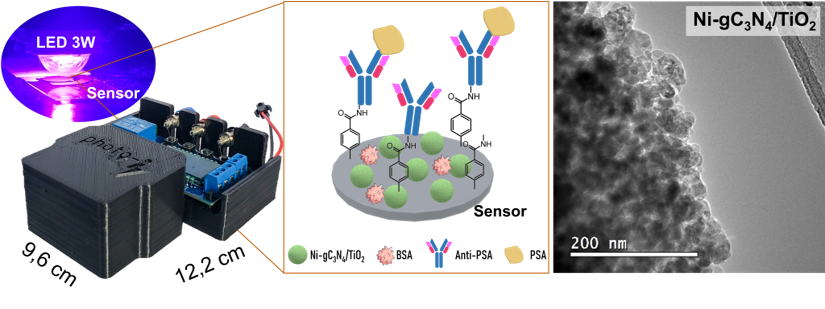

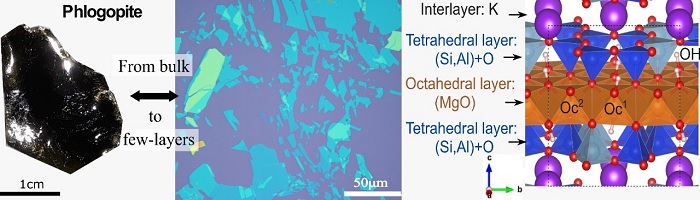

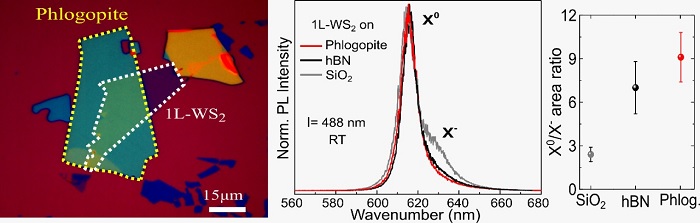

On Wednesday morning, the plenary speaker was a well-known member of the community, the former president of B-MRS Osvaldo Novais de Oliveira Junior (IFSC-USP). The speaker posed a thought-provoking question: can machines generate knowledge? Then he showed that, if computers still cannot transform information into knowledge, they already help a lot, even in the area of materials research. The scientist presented several works that use artificial intelligence tools, mainly machine learning, to analyze large volumes of data in order to discover materials with certain properties or to find papers of interest. In other cases, machine learning tools, coupled with good sensors built with the help of materials technology, make it possible to diagnose diseases using cheap and portable devices. According to the speaker, the next challenge for machines to actually generate knowledge is to understand human language. Physicist with a doctorate in Electronic Engineering and a productive career in the field of materials, Professor Osvaldo began his research on natural language processing in the 1990s from his interest in tools for scientific writing support. Over time, the scientist increasingly connected this research line to Physics and materials, especially in the development of sensors for the healthcare area. “How to teaching natural languages to machines is a very interesting issue for frontier research”, said the researcher, encouraging young people to work in the area.

On Wednesday morning, the plenary speaker was a well-known member of the community, the former president of B-MRS Osvaldo Novais de Oliveira Junior (IFSC-USP). The speaker posed a thought-provoking question: can machines generate knowledge? Then he showed that, if computers still cannot transform information into knowledge, they already help a lot, even in the area of materials research. The scientist presented several works that use artificial intelligence tools, mainly machine learning, to analyze large volumes of data in order to discover materials with certain properties or to find papers of interest. In other cases, machine learning tools, coupled with good sensors built with the help of materials technology, make it possible to diagnose diseases using cheap and portable devices. According to the speaker, the next challenge for machines to actually generate knowledge is to understand human language. Physicist with a doctorate in Electronic Engineering and a productive career in the field of materials, Professor Osvaldo began his research on natural language processing in the 1990s from his interest in tools for scientific writing support. Over time, the scientist increasingly connected this research line to Physics and materials, especially in the development of sensors for the healthcare area. “How to teaching natural languages to machines is a very interesting issue for frontier research”, said the researcher, encouraging young people to work in the area.

See the presentation by Osvaldo Novais de Oliveira Junior:

The Wednesday afternoon plenary was delivered by Natalie Stingelin, professor and director of the School of Materials Science and Engineering at the Georgia Institute of Technology (USA). The scientist showed that plastics, which currently have a strong negative impact on the environment, can be our allies to build a more sustainable world. For that, she said, it is necessary to develop more and better smart electronic plastics, which combine, on the one hand, the flexibility, lightness and easy processing of polymers and, on the other hand, the properties needed for the desired applications. In her charming talk, Professor Natalie, who directs the Center for Photonics and Organic Electronics at Georgia Tech, presented a material of this type developed in her laboratory from a very simple chemical process for applications where it is important to control the passage of light. The material, which is an organic-inorganic hybrid, can be used, for example, in smart windows that keep environments at mild temperatures, avoiding energy expenditure on air conditioning. In addition to the applications, the material offers interesting possibilities for carrying out experiments that can further advance Photonics.

The Wednesday afternoon plenary was delivered by Natalie Stingelin, professor and director of the School of Materials Science and Engineering at the Georgia Institute of Technology (USA). The scientist showed that plastics, which currently have a strong negative impact on the environment, can be our allies to build a more sustainable world. For that, she said, it is necessary to develop more and better smart electronic plastics, which combine, on the one hand, the flexibility, lightness and easy processing of polymers and, on the other hand, the properties needed for the desired applications. In her charming talk, Professor Natalie, who directs the Center for Photonics and Organic Electronics at Georgia Tech, presented a material of this type developed in her laboratory from a very simple chemical process for applications where it is important to control the passage of light. The material, which is an organic-inorganic hybrid, can be used, for example, in smart windows that keep environments at mild temperatures, avoiding energy expenditure on air conditioning. In addition to the applications, the material offers interesting possibilities for carrying out experiments that can further advance Photonics.

After three days of intense scientific programming, from 8:30 am to 7:30 pm, it was time for the traditional Conference Party, whose motto this year was the 20th anniversary of the B-MRS Meeting. The party, exclusively for event participants, was held at Dreams Motor Park, a space that is a bar, restaurant, concert hall and motorcycle museum. Participants of all ages and different geographical origins filled the house and made an unforgettable party. While on stage a rock band played classics of all times, on the dance floor and at the tables the excitement and the joy only increased. “What a lively party we had! It was a moment of relaxation and celebration of life”, expressed Professor Lucimara. A highlight was the participation on stage of a researcher from the community, Raphaela de Oliveira, who performed “Mercedes Benz”, by Janis Joplin. At the end of the event, the doctoral student would once again be highlighted by receiving one of the awards for the best student work.

After three days of intense scientific programming, from 8:30 am to 7:30 pm, it was time for the traditional Conference Party, whose motto this year was the 20th anniversary of the B-MRS Meeting. The party, exclusively for event participants, was held at Dreams Motor Park, a space that is a bar, restaurant, concert hall and motorcycle museum. Participants of all ages and different geographical origins filled the house and made an unforgettable party. While on stage a rock band played classics of all times, on the dance floor and at the tables the excitement and the joy only increased. “What a lively party we had! It was a moment of relaxation and celebration of life”, expressed Professor Lucimara. A highlight was the participation on stage of a researcher from the community, Raphaela de Oliveira, who performed “Mercedes Benz”, by Janis Joplin. At the end of the event, the doctoral student would once again be highlighted by receiving one of the awards for the best student work.

The next day, at 10:30 am, the last plenary session of the event began. Professor Pulickel M. Ajayan (Rice University, USA) spoke about the challenges of nanoscale engineering and the industrial scale-up of its processes, in order to produce increasingly smaller and more efficient devices. Co-founder and director of Rice’s Department of Materials Science and NanoEngineering, Ajayan has a very high impact production in the field, with an h= 209 index on Google Scholar. The scientist emphasized the difficulty of dealing with the interfaces of nanoblocks. “It’s not just about building a Lego,” he said.

The next day, at 10:30 am, the last plenary session of the event began. Professor Pulickel M. Ajayan (Rice University, USA) spoke about the challenges of nanoscale engineering and the industrial scale-up of its processes, in order to produce increasingly smaller and more efficient devices. Co-founder and director of Rice’s Department of Materials Science and NanoEngineering, Ajayan has a very high impact production in the field, with an h= 209 index on Google Scholar. The scientist emphasized the difficulty of dealing with the interfaces of nanoblocks. “It’s not just about building a Lego,” he said.

In addition to these technical-scientific plenary sessions, the event offered, early in the morning of the first day, a lecture on research, development and innovation funding in Brazil. The speaker was Marcelo Bortolini, Director of Scientific and Technological Development at FINEP, an organization of the Brazilian federal government devoted to funding of science and technology in the country. Bortolini showed the instruments that FINEP has to support the entire chain that generates technological innovation, from basic research to the launch of a product on the market. The speaker presented the financing possibilities, both reimbursable (loan) and non-reimbursable (grant) that FINEP offers to universities, research institutes, entrepreneurs, startups and companies.

In addition to these technical-scientific plenary sessions, the event offered, early in the morning of the first day, a lecture on research, development and innovation funding in Brazil. The speaker was Marcelo Bortolini, Director of Scientific and Technological Development at FINEP, an organization of the Brazilian federal government devoted to funding of science and technology in the country. Bortolini showed the instruments that FINEP has to support the entire chain that generates technological innovation, from basic research to the launch of a product on the market. The speaker presented the financing possibilities, both reimbursable (loan) and non-reimbursable (grant) that FINEP offers to universities, research institutes, entrepreneurs, startups and companies.

Watch Marcelo Bortolini’s presentation:

A vibrant, competent and active community

About 1,200 research works were presented, in oral and poster sessions, within the 22 thematic symposia that made up the XX B-MRS Meeting. Organized by teams of researchers from Brazil and abroad, the symposia covered a variety of materials (glassy, ferroic, magnetic, superconducting, electronic polymers, two-dimensional materials, thin films) and their applications in areas such as health, energy, photonics, electronics, and environment. The event also featured 3 technical lectures on advanced materials characterization techniques, offered by scientific instrumentation companies.

Among the symposia, old acquaintances appeared, such as the thirteenth edition of the Brazilian glass and electroceramics symposia, as well as novelties, such as the symposium dedicated to new materials and nanotechnology for agribusiness. “As it was the first time that a symposium addressed this topic at the event, the organizers were positively surprised, both by the interest shown by the public and by the quality of the scientific works”, said Professor Valtencir Zucolotto (IFSC-USP), who was one of the organizers.

Once again, the symposia were thematic forums for the presentation of advances in the synthesis, characterization and application of materials, as well as in the experimental and computational techniques that make these advances possible. Not least, the discussion of the results from questions to the presenters was always stimulated. “In all the presentations, the public asked the speakers interesting questions, raising the scientific level of the event”, commented João Coelho, professor at Universidade Nova de Lisboa (Portugal), one of the organizers of the symposium P, which addressed sustainable materials and technologies for sensors and electronics. “The oral presentations promoted, as expected, interesting technical-scientific discussions between the audience and the presenters”, highlighted professor José Antonio Eiras (UFSCar), co-organizer of the symposium I on ferrous and multiferroic materials.

Once again, the symposia were thematic forums for the presentation of advances in the synthesis, characterization and application of materials, as well as in the experimental and computational techniques that make these advances possible. Not least, the discussion of the results from questions to the presenters was always stimulated. “In all the presentations, the public asked the speakers interesting questions, raising the scientific level of the event”, commented João Coelho, professor at Universidade Nova de Lisboa (Portugal), one of the organizers of the symposium P, which addressed sustainable materials and technologies for sensors and electronics. “The oral presentations promoted, as expected, interesting technical-scientific discussions between the audience and the presenters”, highlighted professor José Antonio Eiras (UFSCar), co-organizer of the symposium I on ferrous and multiferroic materials.

Researchers of all training levels, from undergraduate students to professors, performed the presentations of the thematic symposia. In total, there were more than 340 oral presentations and more than 750 posters. In addition, there were almost 100 invited lectures by leading experts from Brazil and abroad.

While the presentations took place, the works that had applied for the student awards were evaluated. Committees set up by the organizers of each symposium classified the works following the criteria defined by the B-MRS award committee to, at the end of the event, define the list of winners of the Bernhard Gross Prize – a distinction granted by B-MRS to undergraduate, master’s or doctoral students who present the best oral and the best poster of each symposium. The award also involved Professors Ieda Garcia dos Santos (UFPB), B-MRS scientific director, Ivan Bechtold (UFSC), financial director of the society, and Maria Luiza Rocco Duarte Pereira (UFRJ). The trio was in charge of comparing the evaluations of all the finalists and choosing the best works from the entire event to receive the awards sponsored by journals from the American Chemical Society (ACS) and the Royal Society of Chemistry (RSC), which consisted, respectively, of R$2,000 and vouchers of £200 for each winning work, in addition to certificates.

While the presentations took place, the works that had applied for the student awards were evaluated. Committees set up by the organizers of each symposium classified the works following the criteria defined by the B-MRS award committee to, at the end of the event, define the list of winners of the Bernhard Gross Prize – a distinction granted by B-MRS to undergraduate, master’s or doctoral students who present the best oral and the best poster of each symposium. The award also involved Professors Ieda Garcia dos Santos (UFPB), B-MRS scientific director, Ivan Bechtold (UFSC), financial director of the society, and Maria Luiza Rocco Duarte Pereira (UFRJ). The trio was in charge of comparing the evaluations of all the finalists and choosing the best works from the entire event to receive the awards sponsored by journals from the American Chemical Society (ACS) and the Royal Society of Chemistry (RSC), which consisted, respectively, of R$2,000 and vouchers of £200 for each winning work, in addition to certificates.

As a result of this process, the delivery of prizes took place at the end of the event, just before noon on Thursday. In front of an audience of a few hundred people, Professor Ieda called to the stage, one by one, the finalists of the Bernhard Gross Awards: 27 students of all educational levels. Subsequently, the winners of the nine ACS Publications Prizes were announced, whose certificates were presented at the ceremony by the deputy editor of the magazine ACS Applied Nano Materials, T. Randall Lee, and the five RSC Prizes, presented by Natalie Stingelin, who is editor-in-chief of both the Journal of Materials Chemistry C and Materials Advances.

Also at the closing ceremony, the chairlady Lucimara thanked the participants, the sponsors of the awards, the evaluation committees, the sponsors of the event (companies, funding agencies, ICTs), and the B-MRS team.

And in this cycle that always starts again, the awaited moment of the announcement of the next B-MRS Meeting arrived. The event will be held for the first time in Maceió, capital of the state of Alagoas, and for the fifth time in the Northeast region, from 1st to October 5, 2023. Professor Carlos Jacinto da Silva (UFAL), chair of the meeting with Professor Mário Roberto Meneghetti (UFAL), took the floor to present the event’s location, the Cultural and Ruth Cardoso Exhibitions, located in a central area of Maceió, close to the beach and many hotels, restaurants and leisure facilities.

Watch the presentation of the XXI B-MRS Meeting:

At the end of the closing ceremony, there were again long, strong hugs. Gradually, the participants left the Amazônia room, probably with the satisfaction of having participated in a very productive scientific event and the desire to repeat the experience in Maceió. “At the event we saw a lively, pulsating society, with a new generation of competent researchers committed to the development of science”, highlighted chairlady Lucimara. “I’m already excited for the next meeting in Maceió!!!”, she concluded.

The call for symposium proposals to compose the XXI B-MRS Meeting is open until December 3rd this year. The event will be held from October 1st to 5th, 2023 in Maceió (Alagoas, Brazil), chaired by Professors Carlos Jacinto da Silva and Mario Roberto Meneghetti, from the Federal University of Alagoas (UFAL).

The call for symposium proposals to compose the XXI B-MRS Meeting is open until December 3rd this year. The event will be held from October 1st to 5th, 2023 in Maceió (Alagoas, Brazil), chaired by Professors Carlos Jacinto da Silva and Mario Roberto Meneghetti, from the Federal University of Alagoas (UFAL).

On Monday afternoon, Professor Christine Kranz showed the fantastic work of her group at the German University of Ulm (Einstein’s hometown). The group integrates different probe scanning techniques and adapts the instruments to study electrochemical processes while they are happening. The scientist, who is an associate editor of the journal Bioelectrochemistry (Elsevier), showed interesting results obtained with this instrumentation in the study of biofilms and antibacterial materials, catalysts for the production of hydrogen and new batteries.

On Monday afternoon, Professor Christine Kranz showed the fantastic work of her group at the German University of Ulm (Einstein’s hometown). The group integrates different probe scanning techniques and adapts the instruments to study electrochemical processes while they are happening. The scientist, who is an associate editor of the journal Bioelectrochemistry (Elsevier), showed interesting results obtained with this instrumentation in the study of biofilms and antibacterial materials, catalysts for the production of hydrogen and new batteries. On Tuesday morning, Professor Daniel Ugarte (Unicamp) received the José Arana Varela Award. The distinction has been granted annually by B-MRS, since last year, to an outstanding researcher from the Brazilian materials research community, who delivers one of the plenary lectures at the B-MRS Meeting. A world-renowned expert in electron microscopy, Ugarte has distinguished himself in the study of the properties of nanosystems since the beginning of his career, when he was on the cover of the journal Nature as the sole author of an article on fullerene nanoonions. This was the starting point for a series of publications in this and other high-impact journals, such as Science, Nature Nanotechnology, Nano Letters and Physical Review Letters. “He never gives up on his ideals of research excellence and academic integrity,” said Mônica Cotta, who introduced the Ugarte plenary lecture and presented him with the award. But Professor Ugarte’s contribution to the materials community went beyond the papers. In the 1990s, he conceived and set up an open, multi-user electron microscopy laboratory within the Brazilian National Synchrotron Light Laboratory (LNLS), in Campinas. “Daniel’s crazy idea worked extremely well, providing excellent microscopists to the world and forming the basis of what is now known as the National Nanotechnology Laboratory at CNPEM”, highlighted Cotta.

On Tuesday morning, Professor Daniel Ugarte (Unicamp) received the José Arana Varela Award. The distinction has been granted annually by B-MRS, since last year, to an outstanding researcher from the Brazilian materials research community, who delivers one of the plenary lectures at the B-MRS Meeting. A world-renowned expert in electron microscopy, Ugarte has distinguished himself in the study of the properties of nanosystems since the beginning of his career, when he was on the cover of the journal Nature as the sole author of an article on fullerene nanoonions. This was the starting point for a series of publications in this and other high-impact journals, such as Science, Nature Nanotechnology, Nano Letters and Physical Review Letters. “He never gives up on his ideals of research excellence and academic integrity,” said Mônica Cotta, who introduced the Ugarte plenary lecture and presented him with the award. But Professor Ugarte’s contribution to the materials community went beyond the papers. In the 1990s, he conceived and set up an open, multi-user electron microscopy laboratory within the Brazilian National Synchrotron Light Laboratory (LNLS), in Campinas. “Daniel’s crazy idea worked extremely well, providing excellent microscopists to the world and forming the basis of what is now known as the National Nanotechnology Laboratory at CNPEM”, highlighted Cotta.

The Wednesday afternoon plenary was delivered by Natalie Stingelin, professor and director of the School of Materials Science and Engineering at the Georgia Institute of Technology (USA). The scientist showed that plastics, which currently have a strong negative impact on the environment, can be our allies to build a more sustainable world. For that, she said, it is necessary to develop more and better smart electronic plastics, which combine, on the one hand, the flexibility, lightness and easy processing of polymers and, on the other hand, the properties needed for the desired applications. In her charming talk, Professor Natalie, who directs the Center for Photonics and Organic Electronics at Georgia Tech, presented a material of this type developed in her laboratory from a very simple chemical process for applications where it is important to control the passage of light. The material, which is an organic-inorganic hybrid, can be used, for example, in smart windows that keep environments at mild temperatures, avoiding energy expenditure on air conditioning. In addition to the applications, the material offers interesting possibilities for carrying out experiments that can further advance Photonics.

The Wednesday afternoon plenary was delivered by Natalie Stingelin, professor and director of the School of Materials Science and Engineering at the Georgia Institute of Technology (USA). The scientist showed that plastics, which currently have a strong negative impact on the environment, can be our allies to build a more sustainable world. For that, she said, it is necessary to develop more and better smart electronic plastics, which combine, on the one hand, the flexibility, lightness and easy processing of polymers and, on the other hand, the properties needed for the desired applications. In her charming talk, Professor Natalie, who directs the Center for Photonics and Organic Electronics at Georgia Tech, presented a material of this type developed in her laboratory from a very simple chemical process for applications where it is important to control the passage of light. The material, which is an organic-inorganic hybrid, can be used, for example, in smart windows that keep environments at mild temperatures, avoiding energy expenditure on air conditioning. In addition to the applications, the material offers interesting possibilities for carrying out experiments that can further advance Photonics. After three days of intense scientific programming, from 8:30 am to 7:30 pm, it was time for the traditional Conference Party, whose motto this year was the 20th anniversary of the B-MRS Meeting. The party, exclusively for event participants, was held at Dreams Motor Park, a space that is a bar, restaurant, concert hall and motorcycle museum. Participants of all ages and different geographical origins filled the house and made an unforgettable party. While on stage a rock band played classics of all times, on the dance floor and at the tables the excitement and the joy only increased. “What a lively party we had! It was a moment of relaxation and celebration of life”, expressed Professor Lucimara. A highlight was the participation on stage of a researcher from the community, Raphaela de Oliveira, who performed “Mercedes Benz”, by Janis Joplin. At the end of the event, the doctoral student would once again be highlighted by receiving one of the awards for the best student work.

After three days of intense scientific programming, from 8:30 am to 7:30 pm, it was time for the traditional Conference Party, whose motto this year was the 20th anniversary of the B-MRS Meeting. The party, exclusively for event participants, was held at Dreams Motor Park, a space that is a bar, restaurant, concert hall and motorcycle museum. Participants of all ages and different geographical origins filled the house and made an unforgettable party. While on stage a rock band played classics of all times, on the dance floor and at the tables the excitement and the joy only increased. “What a lively party we had! It was a moment of relaxation and celebration of life”, expressed Professor Lucimara. A highlight was the participation on stage of a researcher from the community, Raphaela de Oliveira, who performed “Mercedes Benz”, by Janis Joplin. At the end of the event, the doctoral student would once again be highlighted by receiving one of the awards for the best student work.