Producing microfibers from materials of the graphene family is a challenge some international research groups have decided to face in recent years. Because they are flexible and can readily conduct electricity, these elongated structures of a few tens of micrometers in diameter have several applications, largely as components of flexible electronic devices. However, the methods for microfibers production have failed as regards the control of their dimensions and shapes, impacting the properties of the material.

Now, a scientific team from Brazil, led by Professor Cecília de Carvalho Castro Silva (Mackenzie), has managed to overcome this challenge through an innovative graphene oxide (GO) processing strategy. The research was reported in an article published in Nanoscale, a journal of the Royal Society of Chemistry, featured on the journal’s back cover. In addition, the paper is part of a special edition of the journal, which brings together the work of young researchers with the potential to influence the direction of nanoscience and nanotechnology, which had the participation of Professor Cecília de Carvalho Castro Silva.

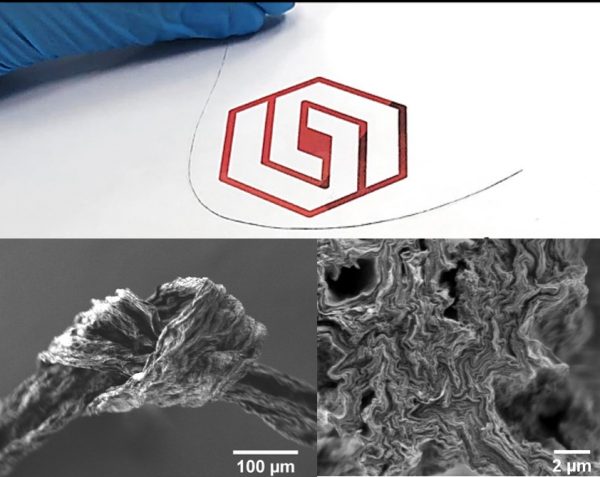

“In this work, we present to the Materials Science and Engineering community a simple strategy to obtain graphene oxide (GO) microfibers with high structural and dimension control, homogeneous shapes and adjustable diameter, through the use of microfluidic,” says Cecília, researcher at MackGraphe, a research center at Mackenzie Presbyterian University focused on graphene and other nanomaterials. The new approach could extend to the production of microfibers based on other two-dimensional or one-dimensional materials.

The work gathered MackGraphe’s expertise in two-dimensional materials for electro-optical devices and the experience of the São Paulo Institute for Technological Research (IPT) in Microfluidics – a multidisciplinary area dedicated to understanding and controlling the behavior of liquid or gaseous fluids on the micrometric scale, using it for this purpose tubes or cameras that confine fluids.

Interaction between fluids

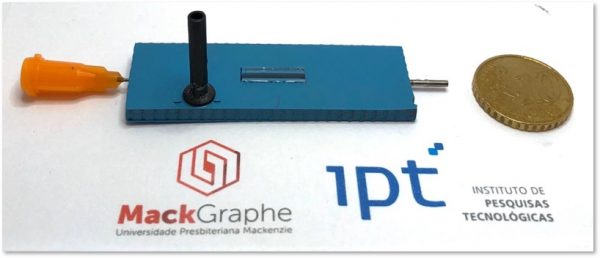

The challenge of the MackGraphe and IPT team was to homogeneously group the graphene oxide sheets, of nanometric thickness, within the desired dimension, forming fibers. Thus, the scientists developed a device composed of needles and micrometric channels that was designed to confine two different liquids so they could interact in a controlled way.

A dispersion of graphene oxide (main liquid) and a compound with coagulating and surfactant properties (support liquid) are injected in the microfluidic device. Both liquids flow together in a channel, in such a way that the support liquid uniformly envelops the main liquid, preventing it from touching the walls of the device. This allows to precisely control the diameter of the fibers leaving the device: the greater the flow of the support liquid, the greater the compression it exerts on the dispersion of GO, and the finer the fibers formed.

To determine how to modulate the diameter of the microfibers according to the flow of the injected liquids, the team used computer simulations. This theoretical work was carried out by researcher Martha Lucía Mora Bejarano, from IPT, using the computational fluid dynamics (CFD) technique.

Flexible transistors

The method developed by the Brazilian researchers includes a phase to improve the electrical properties of microfibers. In fact, graphene oxide, compared to graphene, is a material that is easier and cheaper to produce, but due to the presence of oxygenated functional groups in its structure, it is an electrical insulator. However, simple treatments can remove a part of these elements, generating the so-called reduced graphene oxide (rGO), whose ability to conduct electricity reaches levels close to those of pure graphene.

In the work reported at Nanoscale, thermal and microwave treatments were carried out on microfibers to improve their electrical properties. The result was very positive, and the researchers were able to use graphene oxide fibers to assemble transistors (basic components of electronics that fulfill the fundamental functions of turning on, off or amplifying the electric current). Fully flexible, these transistors could be used in the most diverse wearable devices, from sensors for health monitoring to devices for energy generation and storage in electronic tissues.

Adding competences

The origin of the study dates back to 2017, when Professor Cecília de Carvalho Castro Silva started to develop graphene oxide microfibers in her newly created research group at MackGraphe, and she faced numerous problems regarding the stability of the mechanical properties of the fibers and the control of its thickness and length.

That same year, Cecília was part of the organizing committee of the VII Microfluidics Workshop, which was held at IPT, in São Paulo. The senior IPT researcher Mario Ricardo Gongora Rubio, who has extensive experience in the development of microfluidic devices, was also on this committee.

“In conversations with Mario, we had this idea of exploring the use of microfluidic devices with 3D hydrodynamics, focusing to obtain GO microfibers with high structural and diameter control,” recalls the scientist. As the strategy had already been shown to be effective in obtaining polymeric microfibers, the research team thought about adapting it to the production of graphene oxide microfibers.

The idea was realized in the master’s degree of Jaqueline Falchi da Rocha, which began in 2018 under the guidance of Professor Cecília de Carvalho Castro Silva in the Postgraduate Program in Materials Engineering and Nanotechnologies at Mackenzie. “We had the opportunity to submit a project to IPT’s New Talents Program, which funds scholarships for promising students to develop research in conjunction with the institute,” reports the researcher. The project was approved, and Mario became the co-supervisor of Jaqueline’s work, whose master’s thesis was defended in July 2020.

The research received funding from the Brazilian agencies CNPq, Finep and Fapesp, the Mackenzie Research Fund and IPT.