And now we are back to the history of optical fibers. [See the first part of our story]

In the late 1950s, short optical fibers were already industrially produced and used in certain segments, especially in medicine to inspect the interior of the human body using endoscopes.

In telecommunications, the transmission of information through copper wires and radio waves was established and continued to advance. The first transatlantic copper wire cable was installed in 1956, and the first telecommunications satellite, which used radio waves, was launched two years later. However, the increasing use of the telephone and television was creating an urgent demand to increase the capacity to transmit information.

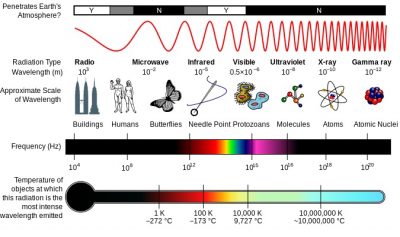

Telecommunication companies in Europe and the United States began to seek solutions in their research labs. Most of the research focused primarily on the use of microwaves and short-wave radio waves, but did not consider the waves of the so-called “optical region,” which is mainly made up of visible light. Yet it was in the waves of visible light where the greatest potential for communications could be found. To give you an idea, for example, these waves can carry tens of thousands of times more information than radio waves.

The emergence of the laser somewhat changed the story of optical telecommunications. Invented in 1960 at a research center of an aerospace company of the United States, the laser began to gain new and better versions throughout the decade. With its ability to emit light in the form of very narrow beams that are preserved over large distances, the laser could be a great partner to fiber optics.

However, the optical fiber was left out because of its enormous attenuation – a reduction in the intensity of the light signal between two points, which is measured in decibels lost per kilometer (dB/km). In fact, using the available optical fibers at that time, only 1% of the light injected into the fiber remained within it 20 meters ahead. Faced with this very low efficiency, other ways of guiding light began to be proposed and tested by some groups, while other researchers continued to invest efforts and resources into radio or microwave waveguides.

The few groups that opted for fiber optics or similar optical waveguides (thin films, for example) in the early 1960s were located at STL (research center of the British telecommunications company STC); at CSF (a strong French business group active in areas such as telecommunications, defense, materials and electronics); at the Bell Labs (US industrial research laboratory then connected to the AT&T telecommunications company), and at the Japanese university of Tohuku.

In the STL group, there was a man called Charles Kao, who would go on to win the Nobel Prize for Physics in 2009 in recognition of his work with fiber optics. Born in Shanghai, China, Kao attended high school at a British college in Hong Kong and moved to England to pursue university studies in electronics and communications, which he loved. He graduated in Electrical Engineering from the University of London in 1957, and soon began working for STC, until he received and accepted a proposal to do a business doctorate in the company’s research arm, STL. There he helped the researcher Antoni E. Karbowiak in his studies on various waveguides until Karbowiak left STL to take up a professorship. At that time, Kao dedicated himself to a project at STL which he believed in, the development of fibers composed of core and coating to be used in telecommunications as guides of visible light waves.

Kao then relied on the help of his colleague, the young engineer George Hockham, to develop his studies on fiber optics. Together they set out to understand the causes of light loss in the fiber to assess whether they could be eliminated or diminished, or whether, on the contrary, trying to lower the attenuation meant facing a losing battle. While Hockham studied the imperfections in the shape or size of the fibers, Kao concentrated on the characteristics of the material, in particular its structure and the impurities and defects. The results of their studies were published in June 1966 in the IEEE Proceedings [K.C. Kao and G.A. Hockham, “Dielectric-Fibre Surface Waveguides for optical frequencies”. Proc. IEE, 113, 1151 (1996)].

This paper can be considered a milestone in the history of fiber optics, since it is the first to report the causes of light loss in fiber optics and it has shown the way forward and the goal to be reached in order to achieve suitable for use in telecommunications.

Based on the characteristics of existing light emitters (laser) and detectors, Kao and his co-author argued that in order to use the fibers in optical telecommunications, it was necessary to lower their attenuation to 20 dB/km. The goal was very challenging, because in the fibers then available the light attenuated 20 dB… every 20 meters! At its best. However, by showing that the main causes of light loss in optical fibers were related to the presence of impurities in the material, which absorbed or scattered light and diverted it from its path, the paper pointed out a way to reduce the attenuation: the use of purest glasses.

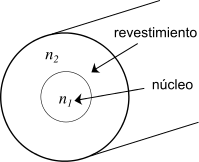

The article concluded that cylindrical fibers composed of a core and a coating, both made of vitreous materials with slightly different refractive indices (higher in the nucleus), could be a much better means for transmitting information than those existing at the time, in addition to being inexpensive.

In these fibers, the information would travel encoded in light signals that would run through the core, while the coating would ensure that the light remained in the nucleus, even in the curves.

After that, Charles Kao continued to focus on fiber optics, investing his time not only in research but also in dissemination. In fact, he lectured on his studies and on the potential of fiber optics in several laboratories and companies around the world. In addition, STL released a press release highlighting the possibilities of fiber optics in the field of telecommunications, with little impact on the press.

In parallel, along with new collaborators, Kao performed a series of experiments with various glasses and other materials and showed, among other results, that in fused silica glass, the attenuation could reach only 5 dB/km. The result was encouraging, but turning that material made of pure silicon dioxide (SiO2) into an optical fiber was another story. Due to its purity, this glass could only be melted at very high temperatures, above 1,500 °C. In addition, after melting, its viscosity made it difficult to transform into any product. Finally, the refractive index of the fused silica was extremely low. Thus, using it to make the fiber core, if on the one hand it would be advantageous in terms of purity, on the other hand it would be very complicated, not only because of the difficulty of processing the material, but also because of the impossibility of finding a material with a lower refraction index for the coating.

At that time, some laboratories from companies in Germany, the United States, France, the United Kingdom and Japan decided to face the challenge of developing low-attenuation fiber optics. Faced with the difficulty of dealing with the fused silica, most of them gave up on this material and tried to make optical fibers with other glasses, removing the impurities. Other groups, on the other hand, gave up making low attenuation optical fibers upon hearing from glass experts who claimed that it would be impossible to remove the impurities that were so problematic.

Only one of these groups made different choices, the Corning company in the United States. Founded in 1851, the company always worked with glasses, but far from stagnating in the production of low value-added products, it led the development of many innovations, starting with the glass globe of Thomas Edison’s incandescent lamp. In the early 1930s, it was at Corning that the chemist Franklin Hyde created the flame hydrolysis method that enabled the manufacture and processing of fused silica. This method, instead of fusing silicon dioxide crystals, is based on a silicon-based liquid compound which when heated on top of a flame, generates a powder that can be deposited forming layers of silica.

In 1966, Corning commissioned physicist Robert Maurer to research and develop fiber optics of less than 20 dB km attenuation for use in optical communications. In 1968, two more scientists had joined Maurer in this project: Peter Schultz, PhD in Glass Science, and Donald Keck, PhD in Physics.

The trio firmly worked on ideas that were opposite to those that the other groups in the world were following. When choosing the material, Corning’s group opted to use the purest glass and added impurities when necessary, instead of removing impurities from less noble glass until it reached the desired attenuation. The Corning scientists then used pure fused silica to coat the optical fiber, which required a material with a lower refractive index, and silica with very small amounts of titanium in the core, in order to increase the refractive index only as necessary and to reduce purity as little as possible.

For the fiber manufacturing method, the Corning group also followed its own path, based on the method Hyde had developed more than thirty years ago. The trio made a tube of pure silica and deposited the doped silica into it. With this fiber, about four years after the start of the low attenuation fiber optic development project, the Corning group obtained the first attenuation measure of less than 20 dB / km. The first low attenuation optical fiber was developed!

In May 1970, the team filed two patents disclosing, respectively, the composition and manufacturing method of this fiber and, thereafter, began to disclose the results.

In 1971, Corning decided that the project could move from the research phase to the development phase, in which engineers worked to make the manufacturing process adequate to make the fiber stronger (the first fiber was more fragile than desirable) and to finalize the development with companies that were interested in buying the fiber. In the mean time, the research team continued to explore, with good results, new possibilities for better optical fibers. Subsequently, Maurer, Schultz, and Keck were forced to devote much of their time to litigation related to the fiber optic patents granted to Corning in 1972 and 1973.

In the early 1970s, fiber optics was not yet commercially available. In fact, it took more than 10 years for insertion of this technology in the market to take place. That part of the story, also interesting, will not be addressed here, but we can cite some landmarks. In 1975, in the United Kingdom, the first non-experimental optical fibers were installed. In 1976, Corning inaugurated its first industrial fiber optic plant. In 1983, in the United States, the first national fiber-optic telephone network was installed. In 1988, the first transatlantic fiber optic cable was installed.

Today, with billions of kilometers of fiber optics installed, telecommunications on planet Earth, mainly via the Internet, relies heavily on these fine glass or plastic wires. With regard to other technologies, fiber optics maintains first place in speed of data transmission, with immense amounts of information that can be transmitted in 1 second between distant points in the planet. With respect to the radio waves that prevailed in optical communications 60 years ago, this capacity increased by no less than a million times. All the effort of everyone involved in the history was worth it, wasn´t it?

To learn more

- Two revolutionary optical technologies. The Royal Swedish Academy of Sciences. https://www.nobelprize.org/nobel_prizes/physics/laureates/2009/advanced-physicsprize2009.pdf

- Making the first low-loss optical fibers. Peter C. Schultz. http://www.peterschultzconsulting.com/wp-content/uploads/2015/03/SchultzOPN2010Makinglowlossfiber.pdf

- Optical fiber spans 30 years. Dr Donald B. Keck. http://www.corning.com/media/worldwide/coc/documents/Fiber/Resource%20Center%20-%20General/r3461.pdf

- City of light. The story of fiber optics. Jeff Hecht. Oxford University Press (1999).