[Text by Jessica Verger Nardeli, co-author of the research, with editorial changes by B-MRS Newsletter].

To produce the new coating, zinc microflakes (Zn) of about 13 µm were dispersed in a polymeric polyurethane matrix synthesized from vegetable oils (biological basis.) The coatings were applied in a AA7475 alloy (modern and competitive material for aerospace applications) to test the corrosion protection.

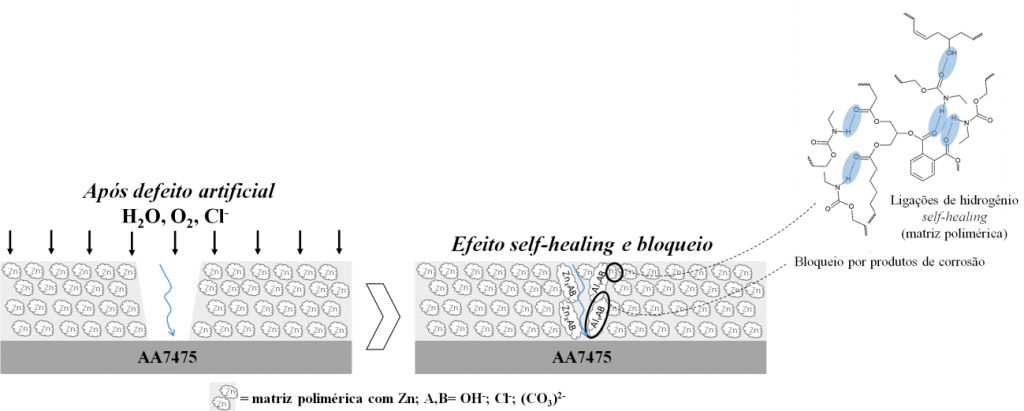

When the coating with zinc microparticles presents a defect, exposing the substrate to the corrosive environment, the dual function starts autonomously (without external intervention). The corrosion inhibiting effect of the zinc pigment combines with the self-healing effect induced by the replacement/increase of hydrogen bonds in the polyurethane polymer matrix, creating a dual function for corrosion protection.

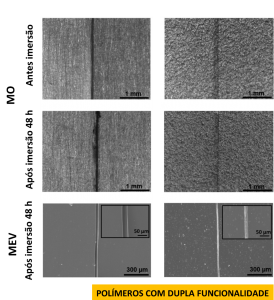

These microscopy images represent a drastic corrosion reduction in an aluminum sheet (AA7475) coated with a Zn-modified coating (right, figure below), when compared to a reference coating. Both samples were artificially scratched and placed in sodium chloride (NaCl) at 0.005 mol/L for 48 hours. In the modified coating, the scratch recovered completely, whereas in the reference coating, the scratch remained until substrate exposure.

“The main contribution of the work is related to the dual function of the coating in a single layer, that is, the self-healing effect attributed to the replacement/increase of hydrogen bonds (polymer matrix) and surface blocking (micro zinc particles) which increases the barrier effect,” summarizes Jessica Verger Nardeli, Ph.D. from the Post-Graduate Program in Chemistry at UNESP and corresponding author with Professor Assis Vicente Benedetti (IQ-UNESP), of the article that reports the research, recently published in the journal Chemical Engineering Journal (impact factor 10.652). “In addition to the self-healing effect of the polymer matrix and the anodic protection (zinc micro-flakes), additional cathodic inhibition is also possible, especially in confined defects in the coating, due to blocking by corrosion products, predominantly those containing zinc and aluminum. Corrosion products limit oxygen access to active sites, slowing down and, ultimately, inhibiting the cathodic reaction,” concludes Nardeli.

Thus, a mechanism for cathodic inhibition in confined defects along with the self-healing effect was proposed according to the schematic representation:

According to Professor Assis Vicente Benedetti, the initial objective of the work was to find a natural and efficient inhibitor for corrosion protection of aluminum alloys, together with an efficient polymer matrix as a barrier against electrolyte permeation. Thus, during her doctorate, Jessica Verger Nardeli performed several experiments based on a series of conventional and localized electrochemical measurements, complemented with computational calculations. “Thus, we had support to elaborate a dual function coating in a single layer,” says Dr. Nardeli.

Novelty of the study

It is well known that there is abundant literature addressing the topic of coatings for corrosion protection of aluminum alloys, but studies focusing on the corrosion protection of the AA7475 alloy, a relatively modern aluminum alloy, are still scarce. Therefore, AA7475 alloy corrosion protection coatings are an important research topic, and even better if these coatings have a dual protective action: self-curing and corrosion inhibition. The bio-based coating modified with zinc micro-flakes developed and applied in AA7475 alloy has both cited properties.

The study received funding from the Brazilian São Paulo Research Foundation (FAPESP). Jessica Verger Nardeli’s doctoral thesis was nominated for the CAPES 2021 Thesis National Award.

Paper: Biobased self-healing polyurethane coating with Zn micro-flakes for corrosion protection of AA7475. Jéssica Verger Nardeli, Cecílio Sadao Fugivara, Maryna Taryba, Fátima Montemor, Assis Vicente Benedetti, Chemical Engineering Journal, 404, 2021, 126478, https://doi.org/10.1016/j.cej.2020.126478.

Contact: Jéssica Nardeli – jeh.nardeli@gmail.com