We are in 1679, in England. The protagonist of the story is Robert Hooke, a polymath who contributed to architecture and experimental science and made several contributions to the understanding of nature. For that, he used the incipient telescopes and optical microscopes that were under development in that century. While using his microscope, Hooke observed that when he dripped water onto the surface of the samples and placed this liquid layer in contact with the instrument, the water adhered to the lens and the images gained clarity and resolution.

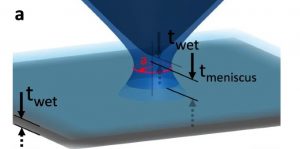

Liquid layers adhered to a surface are called meniscus, and their use at the interface between an optical microscope and a sample became, after Hooke, the basis of the so-called “liquid immersion microscopy.”

We are now in Brazil, at the Center of Microscopy of the Federal University of Minas Gerais (UFMG), more than 300 years after Hooke’s discovery – enough time for humans to develop numerous equipment and characterization techniques, such as microwave impedance microscopy (sMIM).

This technique is one of the newest members of the scanning probe microscopy family. In these microscopes, an extremely fine tip moves over the sample surface. The forces resulting from the probe-sample interaction are measured, which allows reconstructing the image of the sample surface, providing information about some of its properties. In the case of the sMIM technique, a microwave emitter is coupled to an atomic force microscope (AFM). The probe tip of the AFM then functions as a waveguide, and the interaction between the microwaves and the sample provides the information.

The hypothesis was validated through mathematical simulations, carried out within the doctorate in Electrical Engineering of Diego Camilo Tami López, defended in 2020 at UFMG. The modeling of the system, including the formation of meniscus, showed that the thin water slide did concentrate the microwaves, a phenomenon that generated an increase in the resolution of images generated by sMIM.

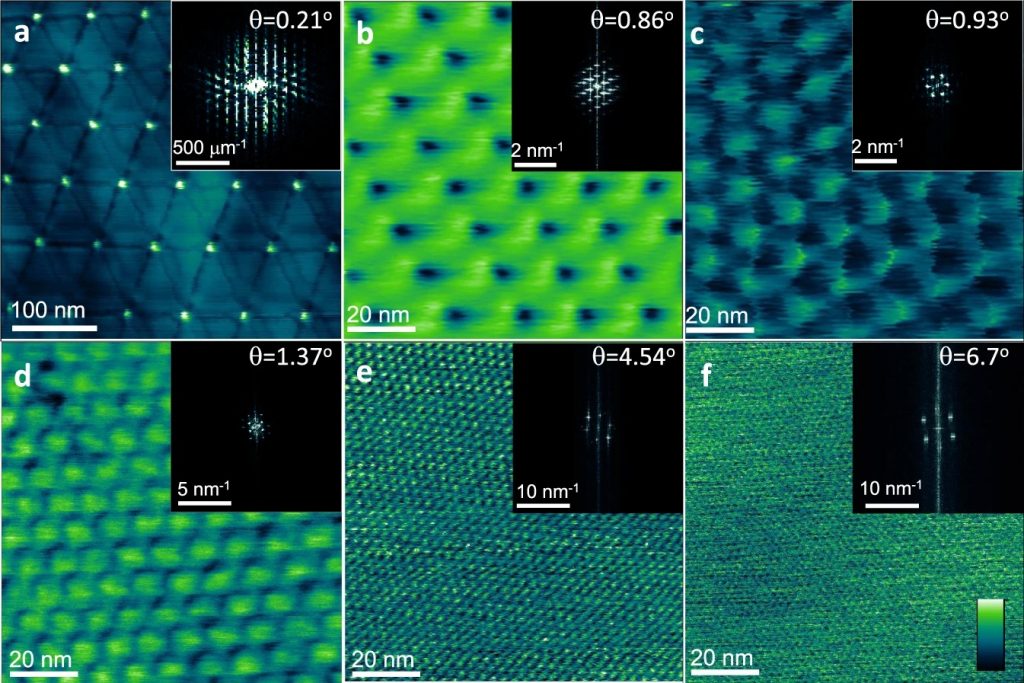

In addition, experimental tests were carried out using samples of twisted bilayer graphene, prepared using a technique recently developed by the UFMG researchers, and published earlier this year. Made up of two layers of graphene stacked and slightly misaligned with each other, the material was chosen by the UFMG team because it offers great versatility in the experiments.

The samples were prepared by scientists from UFMG with the collaboration of researchers from the Federal University of Bahia and NIMS (Japan). The sMIM experiments were carried out by Doug Ohlberg, a scientist who joined the UFMG research group in 2017, after more than 20 years working in the corporate laboratories of Hewlett-Packard in Palo Alto (USA).

In these experiments, by controlling the formation of water meniscus of very few nanometers at the tip of the microscope, the researchers were able to concentrate the microwaves in a controlled manner and go beyond the limits of the sMIM technique, achieving super-resolution.

“We showed that using microwaves as a tool in microscopy can be expanded to a scale of 1 nanometer,” says Professor Gilberto Medeiros Ribeiro (UFMG), corresponding author of the article that reports this research in the journal Nature Communications, in open access format. For non-microscopy specialists: this resolution means that two distinct points can be distinguished at a distance of at least 1 nanometer. “This is important because microwaves represent very low energy radiation, which allows applications in biology,” adds the scientist.

As microwaves have a wavelength between 1 meter and 1 millimeter, this advance indicates the possibility of probing materials at the nanometer scale with much larger waves. “The main contribution of the work is to show how the diffraction limit was surpassed by 100,000,000 times: we were able to make images with 1 nanometer of resolution using a wavelength of 10 centimeters,” says Medeiros Ribeiro.

The research was carried out with funding from the Brazilian agencies CNPq, Finep, FAPEMIG and Capes.

Paper: The limits of near field immersion microwave microscopy evaluated by imaging bilayer graphene moiré patterns. Douglas A. A. Ohlberg, Diego Tami, Andreij C. Gadelha, Eliel G. S. Neto, Fabiano C. Santana, Daniel Miranda, Wellington Avelino, Kenji Watanabe, Takashi Taniguchi, Leonardo C. Campos, Jhonattan C. Ramirez, Cássio Gonçalves do Rego, Ado Jorio & Gilberto Medeiros-Ribeiro. Nature Communications volume 12, Article number: 2980 (2021). Open acces through https://doi.org/10.1038/s41467-021-23253-2.

Contact of the corresponding author: Prof Gilberto Medeiros Ribeiro – gilberto@dcc.ufmg.br