Imagine the following situation. You buy a food packaged with a polymeric film that has the property of keeping insects away. After consuming the food, you place the film in water and it starts to dissolve. Sixteen minutes later, you have a new product: a repellent liquid, ready to be sprayed on your plants.

And now, the reverse process. You pour the liquid into molds and wait a few days. As if by magic, the films spontaneously re-form. You can then use them again as repellent packs.

A material like this was recently developed in Brazil by a scientific team from Unicamp, in collaboration with Embrapa, within Izabella Wyne Inacio Alves Caetano’s master’s in Chemical Engineering, carried out with the guidance of Professor Liliane Maria Ferrareso Lona (Unicamp).

This video shows the polymeric film developed by the Unicamp team breaking up in water and forming a colloidal dispersion.

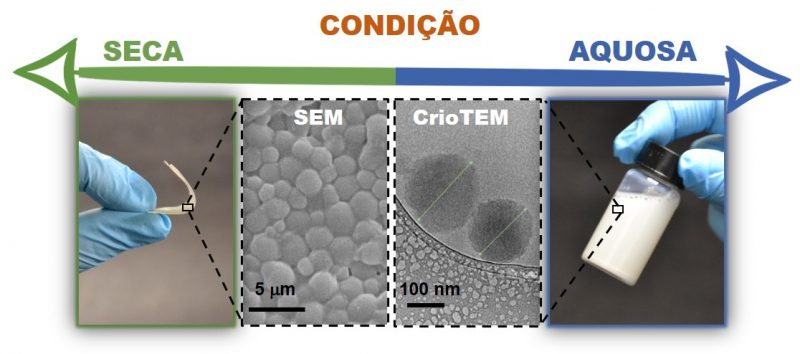

One of the secrets of the new film is its compartmentalized structure. Indeed, under the light of an electron microscope, it is possible to observe that the film contains partitions: spherical polymeric particles of about 500 nanometers, which carry a substance – in this case, neem oil, known for its insecticidal and repellent properties.

The particles help preserve the oil from the degradation that light would cause. At the same time, they allow its release in controlled doses, avoiding waste. When the film dissolves, the tiny particles become dispersed in the water, but they retain their functionality.

This scientific contiribution of the Brazilian team shows the possibility of developing products that the consumer can dismantle using only water, use in another context and rebuild without losing their main properties. Furthermore, the possibility of transforming a liquid into a film (smaller in size and weight) can be used to facilitate the transport and storage of the product and reduce the costs involved.

On the left, the photograph and microscopy image show the compartmentalized film (dry condition). On the right, the film deconstructed in water can be seen, forming a colloidal dispersion containing nanoparticles (aqueous condition).

The work was published earlier this year in the journal Advanced Sustainable Systems. Furthermore, with the help of Unicamp’s Innovation Agency (Inova), the authors filed a patent application on the nanocompartmentalized films in last December.

“The main contribution of this work is the preparation of nanocompartmentalized films with the possibility of upcycling (that is, reuse). Thus, the traditional “linear economy” (discard after use) is directed towards the “circular economy”, prioritizing the sustainability of the process”, says postdoc Filipe Vargas Ferreira, who participated in the work and signs the scientific article as corresponding author with Professor Liliane Lona.

UN and European Union documents suggest that, by 2030, polymeric films used in packaging are manufactured in such a way that they can be recycled or reused. In this context, say the authors of the paper, the upcycling proposal presented in the work constitutes an opportunity to add value to the product, since it increases the functionality of the material and it is in accordance with the new global requirements.

At the beginning, the idea of this work was to prepare a liquid containing nanoparticles (a colloidal dispersion) carrying natural compounds with potential use in pest control in agriculture. To synthesize the nanoparticles, the team chose a commercial polymer blend called ecovio®, which stands out for being compostable, that is, for turning into fertilizer when it is finally discarded. “In the scientific literature, a blend had never been used in an encapsulation process of this type, because it is very difficult to work with more than one polymer in these situations”, reports Professor Liliane. The challenge was overcome by master’s student Izabella after a year of working with her advisor.

Subsequently, new possibilities to reuse the dispersion opened up when the master’s student found that the liquid formed flexible films when left on the laboratory bench for a few days. “When we analyzed these films under a scanning microscope (SEM) we realized that, during drying, the nanoparticles had self-organized, forming compartments in them”, says Izabella, who defended her master’s thesis on this work last year. “Satisfaction was even greater when we verified that the diameter of the particles was maintained when the film returned to the colloidal dispersion form when we added water”, reports Professor Liliane.

The study was funded mainly by the Brazilian agencies FAPESP and CNPq.

The authors of the scientific article. From left: Izabella W. I. A. Caetano, Filipe V. Ferreira, Danilo M. dos Santos, Ivanei F. Pinheiro and Liliane M. F. Lona

Paper reference: Water-Dependent Upcycling of Eco-Friendly Multifunctional Nanocompartmentalized Films. Izabella W. I. A. Caetano, Filipe V. Ferreira, Danilo M. dos Santos, Ivanei F. Pinheiro, and Liliane M. F. Lona. Adv. Sustainable Syst. 2023, 2200430. https://doi.org/10.1002/adsu.202200430

Corresponding authors contact: lona@unicamp.br, f102309@dac.unicamp.br.

Elias José de Sales filho

Toda pesquisa científica que visa a preservação do meio ambiente tem que ser recebida com muita animação pois é por meio de passos como esse que a ciência melhora nossas vidas .