SPI Supplies

Silicon Nitride Membrane

Window Grids

MMR Technologies

Microcryogenic

and

Thermal Stage Systems

National

Electrostatics Corp.

Ion Beams

RBS, PIXE,

AMS

Huntington Mechanical Labs

Better-Built Vacuum Components

Goodfellow

Small quantities … fast!

|

DAY 3

CONTENTS

The 7th Brazilian MRS Meeting (VII Encontro SBPMat) 2008 completed its third day of events, sessions, poster presentations, and the exhibit. Three plenary lectures formed part of the technical sessions during the day. The major event was the conference banquet in the evening.

PLENARY LECTURE 4: BRIAN DERBY Mechanical Properties of Metal Nanowires and Nanoporous Foams

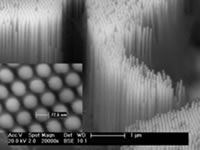

The first plenary lecture on Tuesday was given by Prof. Brian Derby of the Univ. of Manchester, UK. In nanoscience, mechanical properties of materials are significantly influenced by the decreasing size scale. The focus of Derby's talk was mechanical properties of metal nanowires and nanoporous foam. There has been interesting recent work on compression testing of Au nanopillars. Yielding was found to occur in bursts and strength was found to increase with decreasing diameter. In the present work, highly ordered anodic aluminum oxide films with regular pore arrays were used as templates for the electrodeposition of gold nanowires with diameters of 30 – 70 nm. The nanowires were single crystals with different crystal orientations. Compression testing was carried out using a flat punch tip obtained from a Berkovich indenter by cutting off the tip. 70 nm diameter gold nanowires had a yield stress of 600 MPa, while the yield stress of the 30 nm diameter gold nanowires increased up to 1.4 GPa. TEM indicated that deformation appeared to be caused by dislocation motion and possibly twinning. The yield stress had a -0.6 exponent relationship with wire diameter, different from the well known Hall-Petch relationship of exponent -0.5. The dislocation starvation mechanism previously proposed by Greer and Nix appears to be valid here but does not offer any predictive capabilities, said Derby.

In the second part of his talk,

he focused on nanoporous gold obtained by leaching Au-Ag alloys. The

materials has a relative density of 0.2 – 0.45, ligament size of 5

nm – 500 nm and

PLENARY LECTURE 5: GERNOT KOSTORZ Nanostructure and Properties of Materials

In the fifth plenary talk of the conference, and the second of the day, Gernot Kostorz (ETH Zurich) focused on small angle scattering, using x-rays, neutrons and electrons, as one of the important techniques to characterize nanostructural features in materials. He started with a brief introduction to scattering and compared the basic features of the three types of radiation used for scattering studies. He then presented some examples of recent applications. In particular, he described small-angle scattering and diffuse scattering applications in the fields of phase separation on the nanoscale, growth and assembly of nanostructures on surfaces, and coupling of chemical and magnetic inhomegeneities, emphasizing the progress in spatial and temporal resolution achieved in recent years. One example he gave was small-angle neutron scattering of Ni-rich Ni–Ti studied during aging at elevated temperatures, which indicated a complex sequence of phases during decomposition, involving two stages of metastable coherent precipitation preceding the formation of the stable hexagonal phase. Many details of nanostructured materials can now be analyzed with great precision using these techniques. Kostorz's message was that small-angle scattering is here to stay for characterizing nanomaterials.

PLENARY LECTURE 6: FERNANDO GALEMBECK A New Model for Dielectric Charging and Electrostatic Adhesion

In the sixth plenary lecture of the conference, Fernando Galembeck, from the Universidade Estadual de Campinas, Campinas, SP, Brazil, described a new model for dielectric charging and electrostatic adhesion. Galembeck joined a select few by challenging the almost universally accepted assumption of electroneutrality of materials, suggesting a new paradigm for explaining phenomena such as insulator charge inductance and adhesion. Galembeck first recounted historical literature stating that electrostatic charging, although well known, is poorly understood. Controversy still exists as to whether the carriers in insulator charge inductance are ions or electrons. Although some believe that this is a surface phenonemon, there are currently no widely accepted mechanisms for charge acquisition and dissipation in insulators. Consequences include safety problems, such as dust explosions, as well as issues in traditional technologies and nanotechnologies, such a nanofabrication, where electrostatic forces may exceed inertial forces for very small particles. Early work in Galembeck’s laboratory, employing Kelvin probe microscopy, scanning electric potential microscopy (SEPM) or electric force microscopy (EFM), showed that insulator surfaces contain complex but stable patterns of nano-domains. More recently, analytical transmission electron microscopy and electron energy-loss spectroscopy (ESI-TEM) showed that carriers of excess charges in polymer lattices were ions trapped during emulsion polymerization. This was not the case, however, for charge carriers in easily charged insulators, such as polyethylene and other thermoplastics, rubbers, cellulose and silicate glass. Galembeck said that calibration of SEPM instruments led to a procedure for detection of electrostatic patterning of sub-micrometer domains on silica surfaces, and the verification of their dependence on the relative atmospheric humidity. This led Galembeck to a new model for the electrification of insulators. Dissociated water ions or ion clusters are the charge-bearing species, which are deposited on or removed from the solid surfaces according to water-vapor adsorption-desorption. Charge transfer in dielectrics is coupled to mass transfer across the solid-gas interface with a rate that depends on the relative atmospheric humidity, which contributes to surface conductance. Gelembeck applied his new model to the formation and dissipation of electrified domains of several systems. For example, it explains the electrostatic charging of paper and polyethylene. In addition, the detection of the presence of ions in dielectrics has led to a new model for electrostatic adhesion in nanostructured materials; the remarkable but unexpected adhesion between hydrophilic clay and hydrophobic latex particles, which produces new and unmatched mechanical and swelling properties in polymer-clay nanocomposites, is now understood.

Symposium B: Polymeric Nanocomposites for Packaging

and Other Applications in Engineering

In a contributed paper in Symposim B, Guillermo Ruperto, from the University of Sao Paulo, presented his research aimed at using nanocomposites from organophillic clays instead of carbon black as fillers in automobile tires. Rubber, of course, is a product native to Brazil, but so is smectic clay. Ruperto said that there is 20-30 times more clay in Brazil than petroleum in the world, which is the source of carbon black. The smectic clays are treated with ammonium quaternary compounds to form the organophyllic clays. The 40% carbon black filler typically used was replaced by 10% organophylluc clay and 30% inert inorganic material. Vulcanized rubber was then produced using a standard procedure. In addition to being more environmentally advantageous, the modified clays are one-third the weight of carbon black and, when used as a filler, provide the same final volume. In addition, mechanical characteristics, such as rupture tension, rupture lengthening, and hardness, equal or exceed those of vulcanized rubber filled with carbon black. Symposium D: Powder Processing of Novel

Materials

A poster presentation in symposium D by Francisco Araujo Bonfim (Nuclear and Energy Research Institute, Sao Paulo) and Davinson Mariano da Silva (University of São Paulo) presented interesting work on simulating lunar soil compositions and then trying to use this to potentially form useful materials. The motivation for this comes about from future human colonies that might be established on the moon and Mars. Since it will not be cost effective to carry large amounts of material from earth, it would be useful to use the material (soil) available there for various purposes. The NASA Johnson Space Center in Houston has developed several such simulants. In the present study, one of these simulants designated as JSC1-2A that was developed from volcanic ash deposit near Flagstaff, Arizona, was characterized using particle size analysis, scanning electron microscopy, thermal analysis (DTA, TGA), and chemical analysis. The material was found to be close in chemical composition and structural characteristics to the lunar material brought back by Apollo 14, by astronaut Alan Shepard and his crew. In additional interesting work, the researchers created a glass using this simulant material, showing that it is possible to create glasses from lunar soils. Studies such as this can help create a database of such compositions for future use.

Symposium H: Nanomaterials and Nanotechnology

Applied to Biotechnology and

Agriculture

Paulo H.S. Picciani, from the Instituto de Macromoléculas, Universidade Federal do Rio de Janeiro, presented his research on optimizing processing parameters for the electrospinning of polyaniline/poly(lactic acid) fibers. Picciani said that he chose electrospinning because it is inexpensive, is easy to scale up, can produce fibers with thicknesses ranging from nm to mm, and is applicable to a wide range of polymers. Because precise fiber diameter is essential for many applications, Picciani and co-researchers invested the main parameters that contribute to electrospinning small diameter fibers, using hexafluor-2-propanol as the solvent. Considering operational parameters, including polymer concentration, applied voltage and flow rate, the researchers used a factorial analysis to determine the processing conditions required for fiber diameters ranging from 50 nm to 1300 nm. In addition a statistical model was used successfully to fit the operational parameters with a level of significance of p< 0.10. Empirical modeling predicts the experimental results with good accuracy and also indicates that polyaniline concentration plays the major role in the process, although synergy with the others parameters is evident. Symposium J: Applications of Lasers in Materials

Processing

J. M. Drezet, from Ecole Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, presented his work on constructing process maps for laser-beam welding of aluminum alloys, which is a promising alternative to the riveting currently used in the aircraft industry. One motivation for this work is the desire to construct lighter aircraft, which would be more fuel efficient, by increasing the Li content in aluminum alloys. The weldability of the alloys, however, depends on the content of Li and other components. Drezet and co-researchers carried out laser-beam welding on three alloys, differing in Li content. By applying analytical and numerical solutions together with Rappaz-Drezet-Gremaud hot tearing criterion, weldability maps – laser power as a function of welding speed – were constructed. The maps define the region where the full-penetration keyhole mode and crack-free weld seams are obtained. The agreement of the maps with experiment is good.

Symposium L: High Resolution Electron

Microscopy

In symposium C, Leandro Socolovsky (Univ. Buenos Aires, Argentina) gave an interesting presentation on using high resolution TEM (HRTEM) to study magnetic nanoparticles. He presented two examples in his talk. In the first, he focused on the Fe-Cu alloy system. Mechanical alloying is one way to form Fe-Cu alloys. In addition, giant magnetoresistance is observed in granular Fe-Cu systems wherein the GMR effect is due to the presence of magnetic nanoparticles, which appears to be immersed in a non-magnetic matrix. X-ray diffraction (XRD) interestingly did not show bcc iron, only fcc Cu. HRTEM and XRD, along with first principle calculations showed that mechanical alloying produces true Fe-Cu alloys with two species of nanoparticles. One is formed by tiny nanoparticles (3 mm diameter) which are rich in Fe and magnetic. The second larger nanoparticles are rich in Cu, which could be non-magnetic. In the second example, HRTEM and XRD were used to look at silver nanostructures in a system where synthesis of Fe3O4 nanoparticles capped with silver was carried out. Again two species of nanoparticles, small (d~10 nm, iron) and large (d>20 nm, silver and iron with varying compositions) were detected. The large nanoparticles showed silver in the shells. These studies reveal the potential of HRTEM for studying nanoparticles and structures, particularly magnetic ones. However, the full potential of the technique is realized only when used in conjunction with other techniques, said Socolovsky.

ABOUT THE MEETING SCENE

© Materials Research Society, 2008 |